48Hr Non-Stop Operation! InfiRay® Thermal Imaging Monitoring Solution for High-Voltage Substations

Automatic control and unattended operation of electric devices have become a trend with the continuous development of technology. As the smart grid renovation is now in full swing, monitoring of data, environmental parameters, and images of key devices such as transmission and distribution power plants, substations, and transmission and distribution lines is required to keep track of device operation in real time and respond to emergencies on time. In the substation process, transformers, bushings, cable clamps, disconnectors and other key devices are frequently used with high-level reliability requirements. Once overheating occurs, it is liable to cause accidents and affect the safe operation of a substation. Hence, employing thermal imaging to measure temperature and perform diagnoses 24-7 is necessary to avoid undesired consequences.

I. Pain Points

There are various solutions on the market for measuring the temperature of key devices, mostly contact measurement. The implementation of such solutions involves a large number of wiring and device transformations, and requires considerable construction effort. In addition, once implemented, it is difficult to increase or move the temperature measurement points. The traditional measurement system only serves to provide very basic temperature information instead of more explicit images or videos, thus inconvenient for the analysis and solution of problems. Infrared thermal imaging is non-contact remote monitoring, dispensing with any transformation to original devices. The installation of it is simple and can be done for measuring the temperature of a specific point/line/area, together with alarm linkage, avoiding serious consequences caused by overheating as far as possible and minimizing possible losses.

II. Solution Application

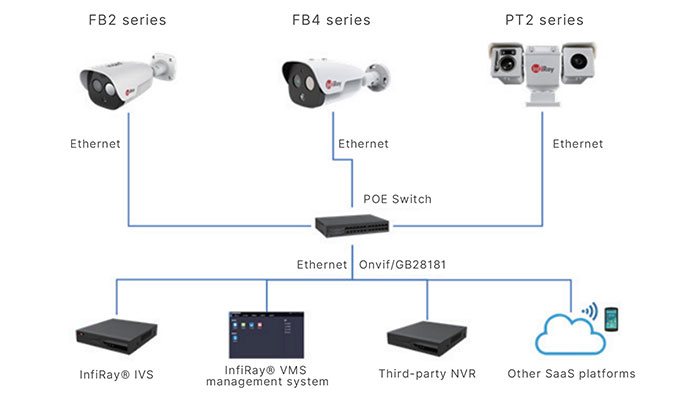

FB2/FB4/PT2 series provide different focal lengths and the choice can be made according to the actual needs. FB2/FB4 camera can be connected with a POE switch for power supply and network access.

Draw the measurement area and set the measurement and alarm rules.

After configuration, use a backend IVS/NVR device or monitoring platform for unified management.

III. System Topology

IV. Solution Strengths

1. Thermal imaging & visible light dual-spectrum imaging enables temperature measurement and monitoring at the same time

2. Multiple focal lengths are available for different monitoring ranges

3. Non-contact temperature measurement, easy installation

4. Wide measurement range from -20°C to 550°C, accuracy up to ±2°C or 2%

5. Point/line/area measurement satisfies various requirements

6. PTZ products support preset point scanning, pattern scanning, patrol scanning and more

7. VMS, a professional temperature monitoring software, is applied, featuring multi-channel view and functions such as temperature statistics and charts

8. Pop-up window/audible and visual/email alarms for early-warning

9. Protocols of Onvif and GB 28181 are supported for secondary development or connection to existing platforms

10. IP66 ingress protection allows for both outdoor and indoor measurement

V. Cases Sharing

1. Monitoring of a wind power company's substation in Jiangsu

PT2 Lightweight PTZ Thermal Camera was employed to monitor the temperature of the main substations 1# and 2#, with a measurement distance of 25-30 meters.

2. A substation in Wuxi, Jiangsu

FB432-T Thermal Camera was deployed to monitor high-voltage disconnectors, featuring 4-level alarms and collecting temperature every 10 minutes.

Product Recommendation

FB2 Series

Thermal imaging & visible light dual-spectrum imaging satisfies the all-weather and 24-hour measurement requirements

Infrared resolution: 256×192

Measurement distance: ≤4m

Measurement range: –20°C~+550°C; accuracy: ±2°C or ±2%

FB4 Series

Thermal imaging & visible light dual-spectrum imaging satisfies the all-weather and 24-hour measurement requirements

Maximum infrared resolution: 640×512

Multiple focal lengths are optional, with a measurement distance of up to 25m

Thermal imaging measurement range: –20°C~+550°C; accuracy: ±2°C or ±2%

PT2 Series

Dual-spectrum imaging; maximum infrared resolution: 640×512

Focal lengths of 9.1mm-35mm are optional, with a measurement distance of up to 30m

4-megapixel visible light camera, supporting 20x optical zoom

Thermal imaging measurement range: –20°C~+150°C or 0°C~550°C; accuracy: ±2°C or ±2%

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar