Unique Advantages of Thermal Cameras in Plate Electrode Monitoring in Electrolytic Tanks to Assist the Metallurgy Industry

In an electrolytic tank, metal purification is implemented by electrolyzing metal materials. In the purification process, metal impurities often accumulate between the plate electrodes, causing short circuits in between. If short circuits occur, a large amount of heat is produced, melting and damaging the plate electrodes and causing device faults. Traditional manual inspection is of low efficiency and can possibly cause omission and incorrect results. The thermal camera can comprehensively and quickly scan the measurement target and automatically capture high-temperature points, helping staff quickly locate the heat defect location, improving maintenance efficiency, lowering maintenance cost, and ensuring manufacturing safety.

I. Main Applications of Thermal Cameras in Plate Electrode Monitoring in Electrolytic Tanks

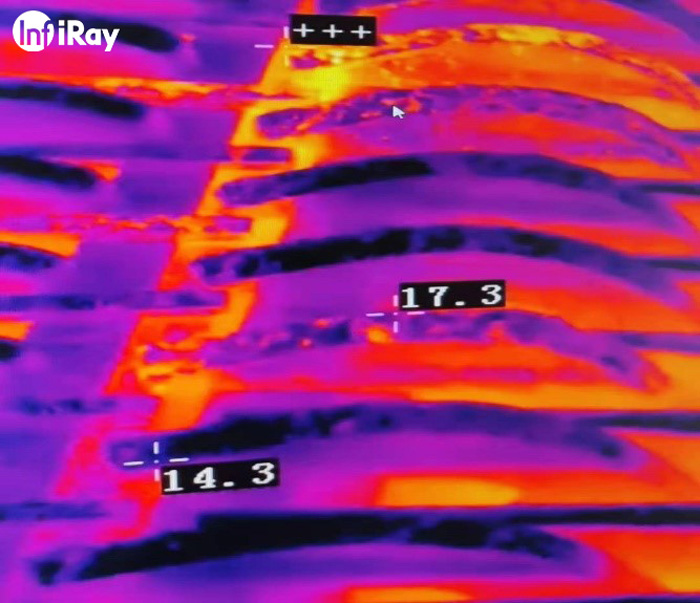

1. Accurately Locating the High-Temperature Points on the Plate Electrode

Thermal cameras collect the thermal image of the electrolytic tank, and the computer processes the thermal image to capture the pixels with exceptional temperature and determine the specific location of the faulty plate electrode. In this way, the short circuit location of the plate electrode in the monitored area is determined.

2. Determining Whether the Plate Electrode Is Short-Circuited and Failed

Thermal cameras are used to monitor the plate electrode temperature, in order to determine the short circuit location in between.

3. Improving the Efficiency and Accuracy of Batch Plate Electrode Inspection

Thermal cameras greatly improve the inspection efficiency compared with that of manual inspection. They reduce the manpower cost and provide a convenient and efficient way for monitoring the electrolytic tank operation.

II. Unique Advantages of Thermal Cameras in Electrolytic Tank Monitoring

1. Non-contact real-time online temperature measurement, with optional lenses, to monitor every corner in the electrolytic tank and the temperature of the narrow space between the positive and negative plate electrodes, missing no high-temperature points in between.

2. If the plate electrodes are not evenly distributed or the positive plate electrode is attached to the negative plate electrode, short circuits occur, causing excessive current and temperature rise on the plate. On the thermal image, the color of the short circuit point is obviously different from surrounding area, staff can quickly locate the fault location, facilitating fault and potential risk troubleshooting and prompt handling.

3. Due to the difficulty in locating high-temperature points on plate electrodes in electrolytic tanks, a second analysis can be implemented on thermal image data, helping staff to accurately determine the failed plate electrode caused by short circuits and high-temperature position of the plate electrode.