3 Reasons to Use the Thermal Camera for Pipeline Inspections

Maintaining the integrity of pipelines is vital for the safe and efficient transportation of various substances. Any damage or leakage in the pipeline can lead to environmental hazards, financial losses, and even jeopardize public safety. Traditional inspection methods may fall short in detecting early signs of deterioration or weak points in the pipeline. This is where thermal imaging technology proves its value. By utilizing thermal cameras, inspectors can identify potential issues such as corrosion, leaks, or insulation problems by capturing temperature variations along the pipeline. Extended Reading: The Versatility of Thermal Imaging Cameras in Oil and Gas.

Major Advantages of Thermal Imaging Technology in Pipeline Inspections:

Thermal imaging technology offers several significant advantages over conventional inspection methods.

A. Non-Destructive Testing: Thermal cameras enable non-destructive testing of pipelines, eliminating the need for invasive procedures. Inspectors can capture thermal images remotely, without interfering with the pipeline's operations or causing disruptions.

B. Early Detection of Anomalies: By detecting temperature variations, thermal cameras can identify potential anomalies that may indicate underlying problems. These anomalies include hotspots, cold spots, or abnormal temperature gradients, which could signify leaks, blockages, or structural weaknesses.

C. Enhanced Safety: Thermal camera allows inspectors to identify potential safety hazards such as overheating or the presence of flammable gases. By addressing these issues promptly, operators can prevent accidents, explosions, or fires, ensuring the safety of personnel and the surrounding environment. Find InfiRay thermal imaging technology that can help you in pipeline inspections here.

Applications of Thermal Imaging Technology in Pipeline Inspections

Thermal imaging technology finds extensive application in pipeline inspections.

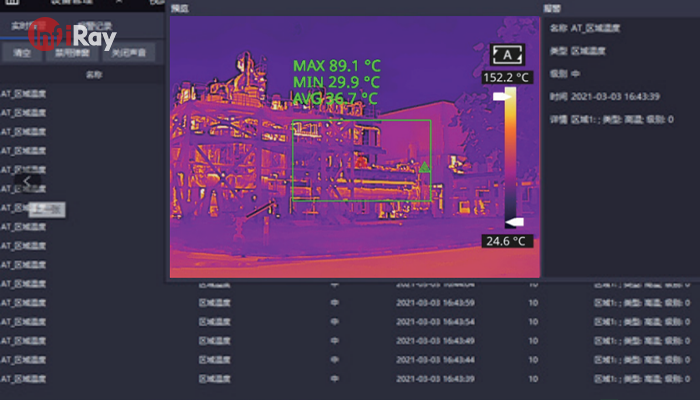

A. Leak Detection: Thermal cameras can detect and locate leaks by capturing temperature differences caused by fluid leakage. This enables operators to address leaks promptly, preventing environmental contamination and minimizing repair costs.

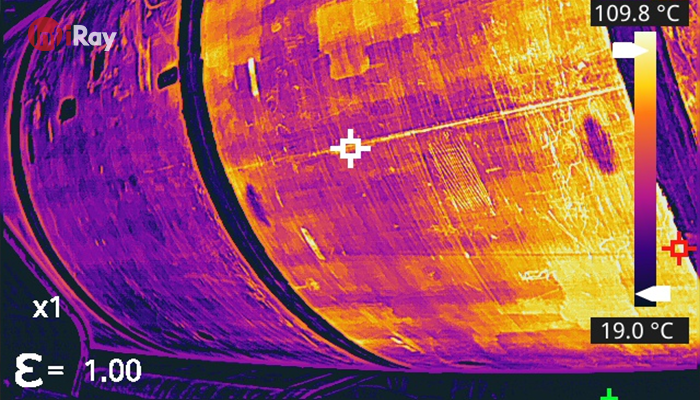

B. Corrosion Assessment: Corrosion is a common issue in pipelines, which can weaken their structural integrity. Thermal imaging can identify areas of corrosion by detecting temperature variations caused by rust or deterioration. Early identification allows for timely repairs or replacement, extending the lifespan of the pipeline.

C. Insulation Assessment: Thermal cameras can assess the insulation effectiveness of pipelines by detecting thermal energy loss or gain along the system. Inefficient insulation can lead to energy wastage, increased operational costs, and decreased system efficiency. They aid in identifying insulation deficiencies for prompt remedial action.

Future Developments and Potential Advancements:

The field of thermal imaging technology for pipeline inspections holds significant potential for future advancements. Some areas for potential growth include:

A. Advanced Data Analysis: With the advent of artificial intelligence and machine learning, the analysis of thermal images can become more automated and accurate. This could improve the detection and identification of pipeline anomalies, streamlining the inspection process.

B. Integration with IoT: The integration of thermal cameras with Internet of Things (IoT) devices and sensors could provide real-time monitoring and alerts. This would enable proactive maintenance and instant notifications of critical pipeline conditions.

Given the numerous benefits of thermal imaging technology in pipeline inspections, it is crucial to encourage further research and its widespread application in the industry. By investing in research and development, fostering collaborations between experts, and sharing knowledge, we can unlock the full potential of thermal imaging technology. InfiRay is committed to the advancement of infrared technology and welcomes partners from all over the world to InfiRay Infrared Open Source Platform.

Thermal imaging technology plays a vital role in maintaining the integrity of pipelines. Its non-destructive nature, early anomaly detection capabilities, and various specific applications make it an indispensable tool for inspectors. Using thermal cameras will lead to more efficient inspections, reduced downtime, improved safety, and substantial cost savings for pipeline operators. As the industry moves towards a more technologically advanced future, further research and application of thermal imaging technology will undoubtedly contribute to safer, more efficient, and cost-effective pipeline inspections.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar