From Preventive Maintenance to Security Monitoring: The Versatility of Thermal Imaging Cameras in Oil and Gas

The oil and gas industry is one of the most hazardous industries, with workers facing numerous risks on a daily basis. Safety is a top priority for companies operating in this sector, and they are constantly seeking new technologies to help improve safety and efficiency. One such technology is thermal imaging cameras, which are proving to be an invaluable tool in the oil and gas industry.

What are Thermal Imaging Cameras?

Thermal imaging cameras, also known as infrared cameras, are devices that use infrared radiation to detect and create images of objects based on the temperature they emit. These cameras are used to detect heat signatures and create images based on the thermal energy emitted by objects.

In the oil and gas industry, infrared thermal cameras are used to identify potential safety hazards and equipment malfunctions. They can detect hot spots in machinery, leaks in pipelines, and even gas emissions that are invisible to the naked eye.

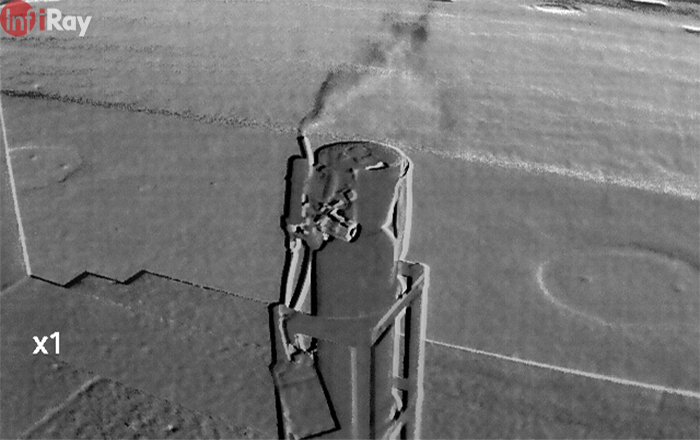

When there is a temperature anomaly around the gas leak, the gas leak area will be displayed as a wisp of smoke on the infrared thermal imaging, enabling visualization of the leaking gas.

How do Thermal Imaging Cameras Work in the Oil and Gas Industry?

Thermal imaging cameras work by detecting the infrared radiation emitted by objects. The cameras use a special lens to focus the infrared radiation onto a detector array, which converts the radiation into an electrical signal. The signal is then processed to create an image that represents the temperature of the object.

In the oil and gas industry, they are used to detect heat signatures and create images of equipment and infrastructure. These images can be used to identify potential safety hazards and equipment malfunctions. Click to see more applications that thermal imaging cameras are used in the industry.

For example, thermal imaging can detect leaks in pipelines before they turn into major spills or identify hot spots in machinery before they cause a fire or explosion. This helps to prevent accidents and injuries and ultimately saves lives.

InfiRay thermal imaging cameras provide real-time monitoring of equipment in the oil and gas industry.

Benefits of Thermal Imaging Cameras in the Oil and Gas Industry

There are many benefits to using thermal imaging cameras in the oil and gas industry. Some of the key benefits include:

1. Improved Safety: Thermal imaging cameras can identify potential safety hazards before they become major issues. For example, they can detect leaks in pipelines before they turn into major spills or identify hot spots in machinery before they cause a fire or explosion. This helps to prevent accidents and injuries and ultimately saves lives.

2. Increased Efficiency: By detecting issues early on, companies can schedule maintenance and repairs in a more timely and efficient manner. This helps to minimize downtime and increase productivity, ultimately leading to cost savings.

3. Environmental Protection: Thermal imaging cameras can detect gas emissions and leaks, helping companies to take action to prevent environmental damage and reduce their carbon footprint. This is becoming increasingly important as the industry faces increasing pressure to operate in a more sustainable and environmentally friendly manner.

4. Cost Savings: By improving safety, increasing efficiency, and reducing environmental impact, thermal cameras can ultimately lead to cost savings for companies operating in the oil and gas industry. Click here to find the thermal imaging camera that can help you with cost savings.

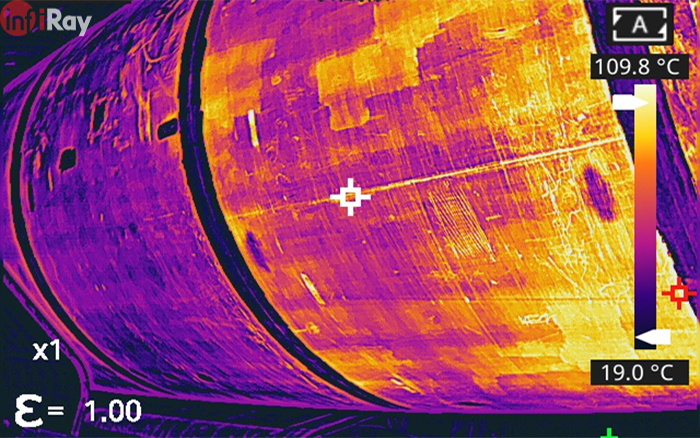

InfiRay thermal imaging cameras monitor pipelines to find potential failures and improve transportation efficiency.

Applications of Thermal Imaging Cameras in the Oil and Gas Industry

Thermal imaging cameras are being used in a variety of applications in the oil and gas industry. Some of the key applications include:

1. Pipeline Monitoring: Thermal imaging cameras are used to monitor pipelines for leaks and other safety hazards. By detecting leaks early on, companies can take action to prevent spills and other environmental damage.

2. Equipment Monitoring: Thermal imaging cameras are used to monitor equipment for hot spots and other safety hazards. By detecting issues early on, companies can schedule maintenance and repairs in a more timely and efficient manner.

3. Gas Emissions Monitoring: Thermal imaging cameras can detect gas emissions that are invisible to the naked eye. By monitoring gas emissions, companies can take action to prevent environmental damage and reduce their carbon footprint.

4. Fire Detection: Thermal imaging cameras can be used to detect hot spots that may indicate a potential fire. By detecting these hot spots early on, companies can take action to prevent fires before they occur. See How InfiRay Thermal Camera Safeguard the Warehouse from Fire.

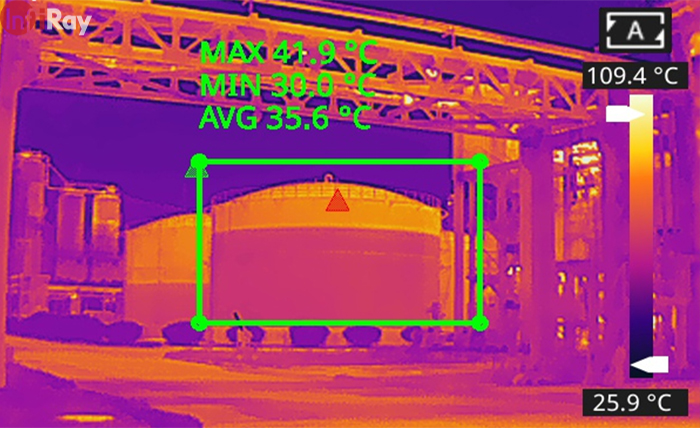

5. Tank Level Monitoring: Thermal imaging cameras are used to monitor tank levels and detect potential leaks. By detecting leaks early on, companies can take action to prevent spills and other environmental damage.

6. Security Monitoring: Thermal imaging cameras can be used to monitor intruders and detect potential security threats. By detecting these threats early on, companies can take action to prevent theft and other security incidents.

InfiRay thermal imaging camera detects the level line directly in the tank

Thermal cameras are proving to be an invaluable tool in the oil and gas industry, helping to improve safety and efficiency while reducing environmental impact and costs. While there are some challenges and limitations to their use, the benefits of thermal imaging cameras in this industry are clear. As the industry continues to face increasing pressure to operate in a more sustainable and environmentally friendly manner, thermal imaging cameras will likely play an increasingly important role in ensuring the safety and efficiency of operations.