The Future of Manufacturing: How Smart Thermal Cameras Are Leading the Way

Manufacturing processes have evolved significantly over the years, incorporating cutting-edge technologies to streamline operations, enhance efficiency, and improve product quality. One such technological innovation that is revolutionizing the manufacturing industry is the use of smart thermal cameras. These advanced devices can capture and analyze thermal data, providing invaluable insights that enable manufacturers to optimize their processes.

Why Thermal Cameras Can Help Manufacturing?

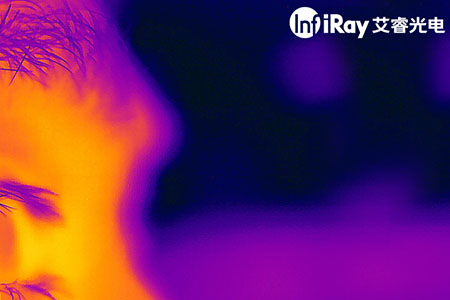

Smart thermal cameras are specialized imaging devices equipped with advanced sensors that can detect and measure temperature variations in real time. By converting thermal energy into visible light, these cameras create detailed thermal images with temperature data. These thermal images provide a comprehensive view of the temperature distribution across an object or a scene, enabling manufacturers to identify anomalies, monitor equipment performance, and ensure product quality. Discover additional options for thermal imaging solutions in the manufacturing industry here.

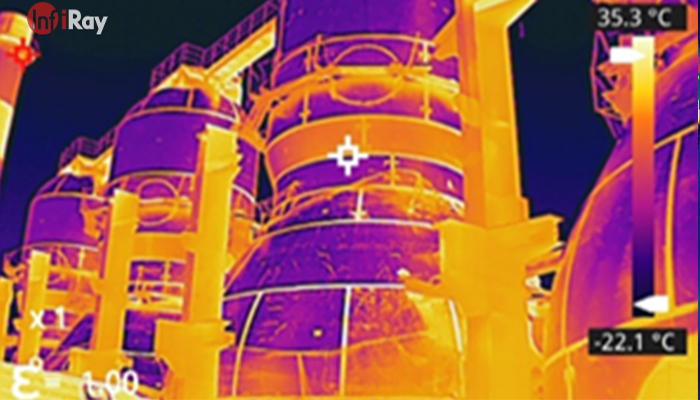

Thermal imaging can detect the temperature of the plant equipment in a wide range of conditions

Application of Thermal Cameras in Manufacturing

The application of smart thermal cameras in manufacturing is vast and diverse. One of the primary applications is in predictive maintenance. By continuously monitoring the temperature of machinery and equipment, thermal cameras can identify potential faults and detect overheating issues before they cause costly breakdowns. This proactive approach minimizes downtime, improves productivity, and reduces maintenance costs.

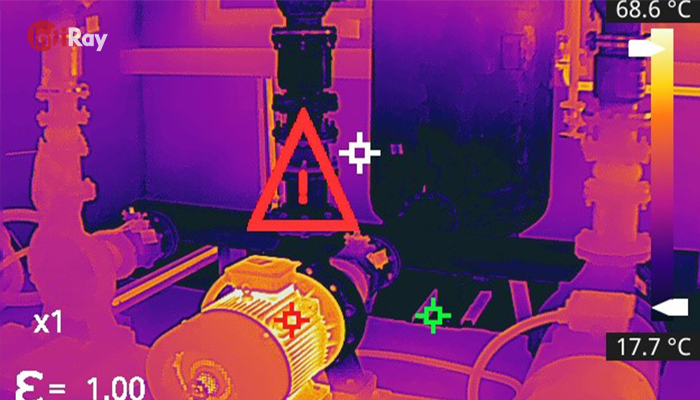

Smart thermal cameras also play a crucial role in quality control and inspection processes. They can detect defects, irregularities, or temperature variations that may affect product performance or safety. Whether it's detecting faulty electrical connections, monitoring heat distribution in electronic components, or detecting abnormal situations in products. these cameras provide a non-intrusive and efficient method for identifying issues that may not be visible to the naked eye. Have you considered the additional capabilities of smart thermal cameras?

A plant placed the InfiRay AT20 3m away from the inspected equipment.

Advantages of Using Thermal Cameras in Manufacturing

The advantages of using smart thermal cameras in manufacturing are numerous. Firstly, they enable real-time monitoring, allowing manufacturers to continuously assess and control temperature-related parameters. This capability ensures consistent product quality, reduces waste, and prevents the production of defective goods. Additionally, by identifying and rectifying potential issues promptly, manufacturers can avoid costly repairs, minimize downtime, and maximize operational efficiency.

Another advantage is the ability to perform inspections without interrupting the manufacturing process. Unlike traditional methods that often require equipment shutdown or dismantling, thermal cameras can assess temperature variations remotely, making inspections faster, more cost-effective, and non-disruptive. This feature significantly improves productivity and minimizes operational disturbances. Looking for thermal cameras to aid in manufacturing? Check out our selection.

InfiRay thermal imaging camera alerts immediately after detecting abnormal temperatures

What Can Thermal Cameras Do in the Future?

Looking ahead, the future of smart thermal cameras in manufacturing is promising. As technology advances, these devices will become even more powerful, compact, and affordable, making them more accessible to a wider range of manufacturers. In addition, the progress made in artificial intelligence (AI) and machine learning (ML) will empower thermal cameras to carry out automatic analysis and produce practical observations. This integration will further enhance the efficiency and effectiveness of manufacturing processes.

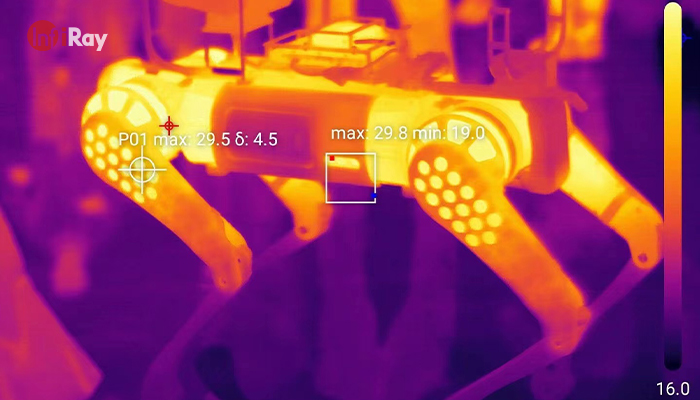

Moreover, the integration of smart thermal cameras with other emerging technologies, such as the Internet of Things (IoT) and cloud computing, will enable real-time data analysis, remote monitoring, and predictive analytics. Manufacturers will be able to harness the power of big data to optimize their operations, make informed decisions, and improve overall productivity.

InfiRay thermal Imaging Equipment That Can Be Mounted on Mining Robots

Smart thermal cameras are revolutionizing the manufacturing industry by providing valuable insights into temperature variations, optimizing processes, and offering a range of benefits such as predictive maintenance and quality control. These cameras enable real-time monitoring, non-intrusive inspections and can significantly reduce costs. As technology advances, smart thermal cameras will continue to be indispensable in manufacturing, raising the bar for efficiency, productivity, and quality. Considering the many advantages, why not explore the world of InfiRay smart thermal cameras further?

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar