Must Read Before Buying an Industrial Thermal Camera: 7 Key Factors to Consider

Industrial thermal cameras have become indispensable tools in various industries, from industrial inspections to security and surveillance. Their ability to detect and visualize heat signatures has revolutionized how we perceive the world around us. However, with an array of them available in the market, choosing the right one can be overwhelming. To ensure you make an informed decision, this blog will shed light on the essential factors to consider before purchasing an industrial thermal camera.

1. Resolution: Capturing the Fine Details

One of the most critical factors to consider when buying an industrial thermal camera is its resolution. Resolution determines the level of detail in the thermal images. Higher resolution cameras have more pixels, allowing them to capture finer details. For industrial inspections, a higher resolution is advantageous, enabling you to identify and analyze smaller defects and anomalies with greater accuracy.

Definition and accuracy are the most important features

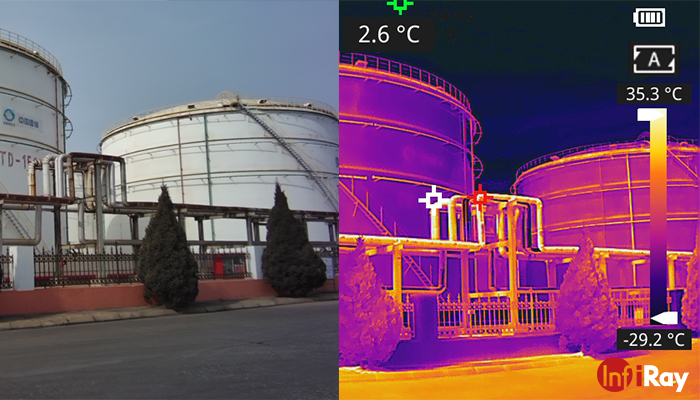

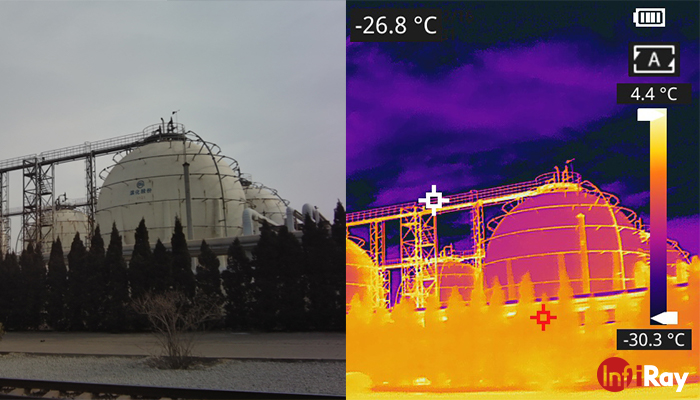

2. Temperature Range and Sensitivity: Detecting Subtle Temperature Variations

The temperature range and sensitivity of an industrial thermal camera play a vital role in its performance. The temperature range indicates the minimum and maximum temperatures the camera can measure accurately. Choose a camera with a wide temperature range that covers the temperatures relevant to your application.

Additionally, consider the camera's sensitivity, often measured as Noise Equivalent Temperature Difference (NETD). Lower NETD values indicate higher sensitivity, allowing the camera to detect subtle temperature differences. This is crucial for identifying potential issues in industrial processes and equipment.

3. Optics and Lens Options: Zooming in or Wide-Angle Views

The versatility of an industrial thermal camera heavily depends on its optics and lens options. Different lens types offer varying field of view (FOV) and focal lengths. Wide-angle lenses are suitable for capturing larger areas, making them ideal for facility monitoring and surveillance. On the other hand, telephoto lenses provide a narrower FOV, allowing for detailed inspections of distant objects or hard-to-reach areas.

4. Frame Rate: Real-Time Monitoring

For applications that involve dynamic processes or moving objects, frame rate becomes crucial. Frame rate refers to the number of frames per second (fps) an industrial thermal camera can capture. A higher frame rate ensures real-time monitoring and accurate depiction of fast thermal changes, making it essential for tasks such as predictive maintenance and quality control.

InfiRay thermal camera can measure accurate temperature in industrial facilities

5. Integration and Connectivity: Seamless Data Transfer

An industrial thermal camera's integration and connectivity capabilities are significant factors to consider, especially in industrial environments with existing systems and protocols. Look for cameras with multiple connectivity options such as USB, HDMI, Ethernet, and wireless connectivity. This allows for easy data transfer, integration with industrial systems, and remote control.

6. Software and Analysis Tools: Unleashing the Power of Data

The availability of advanced software and analysis tools can greatly enhance the usability and effectiveness of your industrial thermal camera. Seek cameras that come with user-friendly software for data analysis, report generation, and image processing. These tools enable you to extract valuable insights from thermal data, optimizing your industrial inspection processes.

7. Environmental Protection (IP Rating): Withstanding the Elements

Industrial environments can be harsh, with exposure to dust, moisture, and potential hazards. To ensure the longevity and reliability of your industrial thermal camera, consider its Ingress Protection (IP) rating. An IP rating indicates the camera's resistance to dust and water ingress. Choose a camera with an appropriate IP rating that matches the environmental conditions of your industrial setting.

Conclusion:

Investing in an industrial thermal camera is a decision that requires careful consideration of several key factors. By paying attention to resolution, temperature range, sensitivity, optics, frame rate, integration, software, and environmental protection, you can make an informed choice that aligns perfectly with your specific industrial inspection needs.

Whether you are conducting preventive maintenance, analyzing heat distribution, or enhancing security and surveillance, a well-chosen one will unlock a new realm of possibilities for your business or organization. Remember that each application may have its unique requirements, so take the time to assess your needs and select an industrial thermal camera that delivers optimum performance and value for your investment.