Why Thermal Imaging Boosts LED R&D and Quality Control

Effective heat dissipation is crucial for maximizing the lifespan of LEDs, making thermal management a key factor in LED applications and development. In this article, we explore the significant advantages of utilizing infrared thermal imaging in LED product research and quality management monitoring.

I. Unique Advantages of Infrared Thermal Imaging in LED Development and Quality Management

1. Non-contact Temperature Measurement:

· Automatic capture of the hottest points in the entire screen or a specific area.

· Intuitive identification and precise location of problematic points.

· Reliable and accurate detection of fault origins.

2. Automatic Data Collection and Analysis:

· Target temperature data is automatically collected and presented in curves.

· Facilitates visual analysis of temperature development trends.

3. Alarm Functionality:

· Set alarm thresholds to trigger alerts when temperatures reach specified ranges.

· Enables prompt action to address problematic products.

4. Support for Secondary Development:

· Provides SDK development packages for automation and device integration.

II. Key Applications of Infrared Thermal Imaging in LED Product Development and Quality Management

1. Research and Development:

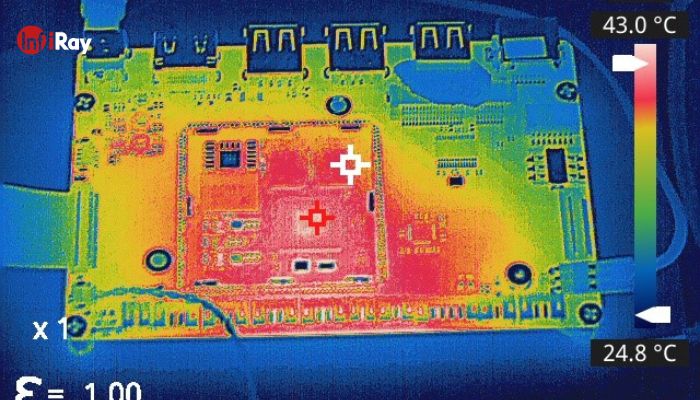

(a) LED Module Driver Circuit Temperature Detection: - Identifying temperature anomalies in circuits for efficient circuit design.

(b) LED Light Source Semiconductor Chip Temperature Detection: - Analyzing semiconductor chip heat distribution during operation to enhance product lifespan.

(c) Light Attenuation Test Temperature Detection: - Correlating temperature with light attenuation to address product quality issues.

2. Quality Management:

(a) Semiconductor Lighting: Uniformity Check for Blown Bulbs: - Improving glass blowing processes through infrared thermal imaging for enhanced product yield.

(b) LED Chip Pre-encapsulation Temperature Detection: - Detecting temperature anomalies before encapsulation to reduce waste.

III. Recommended Thermal Imaging Stars:

1. AT31F/61F Fixed-focus Online Temperature Measurement Thermal Imager:

· Various focal length lenses for different detection needs.

· I/O alarm output for external alarm device linkage.

· Rich backend interfaces for easy integration into monitoring systems.

2. AT31/61 Motorized Focus Online Temperature Measurement Thermal Imager:

· Autofocus for convenient on-site application.

· Power over Ethernet (POE) for simplified cable layout.

· Comprehensive software functions for external alarm device linkage.

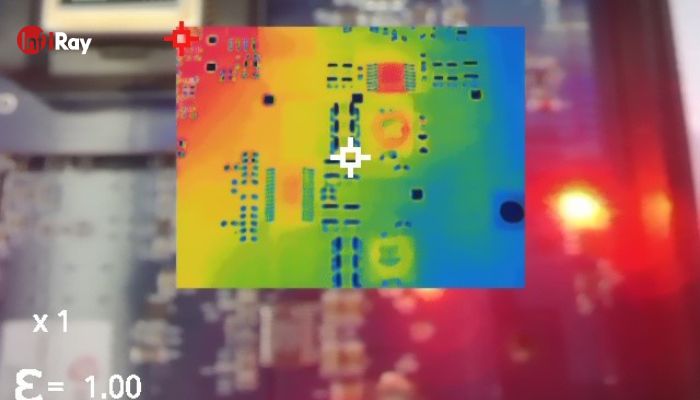

3. M300/600 Handheld Temperature Measurement Thermal Imager:

· Manual focus support for discerning small targets.

· Dual light fusion for improved observation in complex environments.

· Intelligent high and low-temperature alarms for timely fault resolution.

· WIFI transmission for real-time temperature data sharing.

IV. The Control Center: Software System:

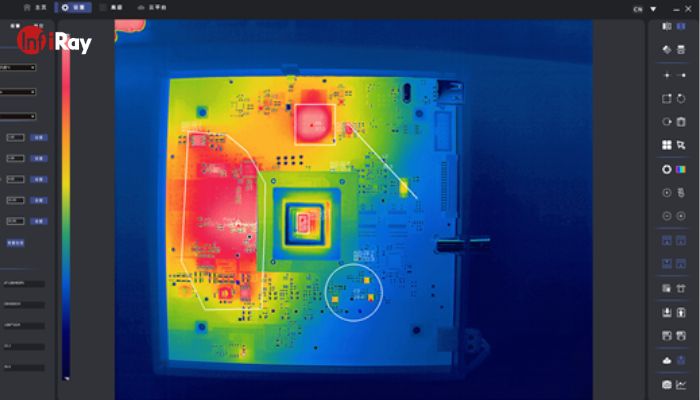

Recommend pairing with InfiRay professional temperature analysis software.

1. Real-time temperature display.

2. Area temperature measurement with customizable alarm ranges.

3. Historical data query and image analysis for further research.

4. High and low-temperature alarms with multiple alert options.

V. Tips for Capturing High-Quality Infrared Thermal Pics:

1. Choose a high thermal sensitivity infrared thermal imager for scenarios with small temperature differences.

2. Select the appropriate infrared thermal imager product or mode based on different scenes and temperatures.

3. Use the automatic mode to measure temperature ranges, then manually set horizontal and span parameters for optimal results.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar