Sharp Eyes for Safety Monitoring in Hazardous Chemicals Warehouse: Infrared Thermal Camera

At the turn of the year, all kinds of production and business activities are carried out actively, bringing increasing uncertain factors to safety production. Hazardous chemicals have the characteristics of large volume, wide distribution, rich varieties, and high risk. It can be said that the safety monitoring of hazardous chemicals is the top priority of safety production.

Chemical/hazardous chemical accidents

As the leader of thermal imaging in China, with continuous R&D, InfiRay delivers infrared thermal cameras providing clear images and accurate temperature measurement for the market. These "real-time online safety officer" provides all-day continuous service for the production line to escort the safety production.

Due to the characteristics of flammability and explosiveness, the safety of hydrogen has attracted much attention. A company has encountered the dilemma of how to carry out safety monitoring in the process of loading, unloading, and storage of hydrogen.

After a full understanding of customer demand and on-the-spot investigation of practical application scenarios, InfiRay® decided to use InfiRay® AT Series Automatic Focusing Online Temperature Measurement Thermal Camera for on-site temperature and environmental monitoring.

The infrared thermal camera can monitor the temperature of the valve, pipeline, and surrounding environment in real-time during loading and unloading hydrogen. The monitoring system also has an alarm function. When there is an abnormal temperature, it can trigger the networked alarm device, and timely inform the staff to take safety measures or evacuate to a safe area.

Applied with the second generation algorithm of electric automatic focusing, the AT series can provide real-time images and temperature data monitoring, which can be widely used in process control, quality inspection, status monitoring, fire warning, and other aspects.

According to the specific needs of the customers, InfiRay® offers the following solutions:

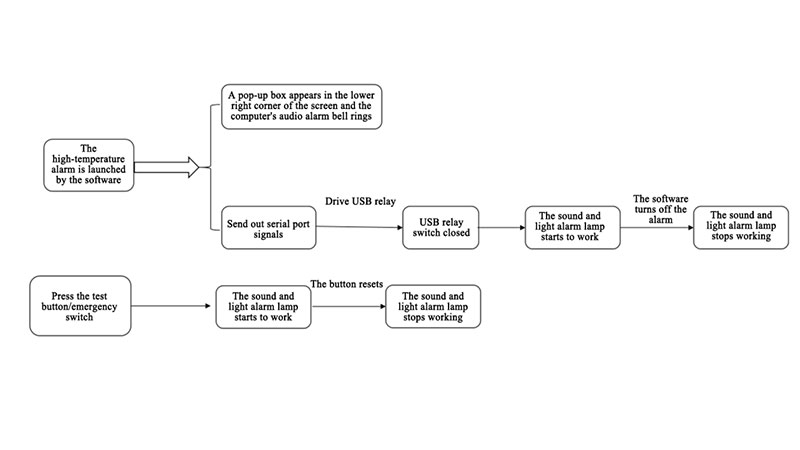

1. The sound and light alarm lamp is controlled by a USB relay, whose switch is connected in series with the power supply circuit of the alarm lamp. The USB relay needs a serial port signal to drive the action and customize the software function;

2. According to the size provided by the customer's technical personnel, the preliminary installation plan can be issued. With the rotation of the PTZ, the overall coverage of the tail of the torpedo vehicle can be realized;

3. It is integrated into the PTZ by the customer and installed at a height of 5 meters to monitor the hydrogen storage area on the back;

Combined with the customer application scenario, after the installation and debugging on site, the AT series has achieved the expected effect and met the actual needs of the customers.

InfiRay® infrared thermal camera is a perfect maintenance tool for hazardous chemicals warehouse. Its advantages are as follows:

01. The infrared thermal camera can measure the temperature without contact, which can guarantee and maintain the personal safety of personnel as much as possible without disturbing the operation of the equipment;

02. The infrared thermal camera can measure the surface temperature, visualize the temperature, and intuitively find the temperature change and the temperature difference between different targets;

03. Compared with the traditional temperature measurement tools, the infrared thermal camera can visualize the temperature and expand the measurement range;

04. The infrared thermal camera can complete real-time observing and recording, thus identifying the problem points quickly and analyzing the causes after the danger is eliminated;

05. The on-line infrared thermal camera can automatically monitor the target all day long, and alarm immediately when problems are found, saving a lot of manpower and material resources;

Other application scenarios of InfiRay®'s infrared thermal camera in hazardous chemicals monitoring

1. Temperature monitoring of hazardous chemicals storage cabinet/pallet tank

It is necessary to measure and control the surface temperature of the container due to the active chemical properties of hazardous chemicals. The AT31F/61F of the AT series Automatic Focusing Online Temperature Measurement Thermal Camera is installed on the top or side of the container. At the same time, the overall temperature of several containers is monitored. In case of an abnormal temperature rise, the alarm will be given immediately. Its excellent networking capability enables us to monitor the temperature of multiple groups of containers in one software at the same time.

2. Overall temperature measurement of warehouse

In addition to containers containing hazardous chemicals, temperature control in other areas is also very important. The AT series Automatic Focusing Online Temperature Measurement Thermal Camera is installed on the roof of the warehouse to detect the overall temperature of the warehouse, so as to prevent possible abnormal temperature and give an alarm in advance.

3. Temperature inspection of other equipment in the warehouse

For the electrical cabinet, connecting line, and other equipment in the warehouse, as well as some areas that are difficult to be detected by the on-line infrared thermal camera, we can use Tianshu C200/Tianxuan M300 Handheld Thermal Camera to conduct regular inspection, find out the hidden danger in time, and take preventive measures.

Safety monitoring of hazardous chemicals is the most important part of safety production. InfiRay® temperature measurement infrared thermal camera can provide all-day infrared thermal imaging temperature monitoring and take targeted safety troubleshooting measures in advance to ensure safe production.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar