Applications of InfiRay Light-Load PT Camera for Thermal Cameras in Power Inspection

With the continuous advancement of technology, automatic control and unattended operation of electric devices have become an inevitable trend. Currently, the smart grid reconstruction project has been fully rolled out. Central control centers need to be built to monitor key equipment such as the power transmission and distribution plants, substations, and transmission and distribution lines, to satisfy the need of developing intelligent and centralized monitoring for the modern power industry. The temperature measurement and diagnosis functions provided by thermal cameras are extremely vital for scheduled/on-demand remote online temperature of primary equipment such as the generator step-up (GSU) transformer.

Application Background:

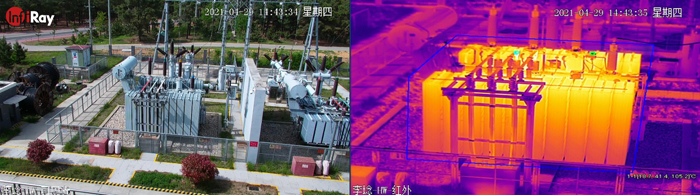

①Modern electric devices feature high power voltage grades and large capacity, and this creates more requirements for the electric device status maintenance;

②Traditional manual inspections and visible-light video monitoring do not satisfy such monitoring requirements and cannot spot thermal-related defects in the device;

③The device status maintenance depends on the status detection during operation and online monitoring methods. Traditional detection methods will cause safety risks;

④Traditional monitoring methods cannot provide operations related to the fault properties, such as the real-time monitoring of the heat distribution fields and fault property diagnosis of the thermal image. This will usually cause delayed monitoring and great property loss.

Application Example:

A power company in Jiangsu Province wants to install thermal cameras to monitor the power equipment and has the following requirements:

①Visible light, thermal videos, and temperature information can be fed into the hard drive recorder in the current system, and the temperature of GSU transformers 1# and 2# can be uploaded in real-time.

②Customizable preset and scheduled cruise functions need to be supported.

③Alarm linkage should be equipped. When the temperature exceeds the 110°C thresholds, the equipped client software should report and upload alarms. There should be functions such as audio prompt, linkage image capture, video recording, pop-up window preview, and export of history temperature curves of the measured area.

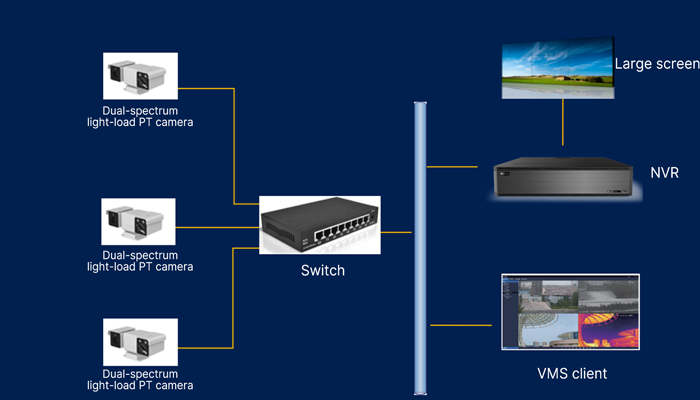

Based on the company's requirements, InfiRay installs multiple PT264 thermal light-load PT cameras for cruise and non-stop monitoring. Multiple regions of interest (ROIs) are specified to ensure reliability and promptness as well as accurate temperature measurement in outdoor harsh environments.

The front-end PT264 thermal light-load PT cameras are installed on the upper area of the comprehensive office building. The transmission is implemented through optical transceivers and network switches connected to the existing back-end NVR of the customer and the InfiRay VMS client, to monitor the temperature of GSU transformers 1# and 2# with an interval of 25 to 30 meters.

Solution Strengths:

1. The all-weather automatic scheduled cruise reduces manpower, and ONVIF is supported to access the hard drive recorders of mainstream manufacturers;

2. Compared with the medium-load PT cameras, light-load PT cameras provide better price-performance with the same image effect, temperature accuracy, and measurement distance. This reduces the cost for the customer;

3. Non-contact temperature measurement does not affect the objects to be measured and measures all temperature points of the image. The hottest point on the entire screen or the area is automatically captured for users to directly see the problem and efficiently locate problems without omission.

As a leading manufacturer of uncooled IRFPA, InfiRay will leverage its cutting-edge technology and mass production capabilities to present its infrared imager series with a smaller size, lower power consumption, higher performance, and lower cost, as well as professional infrared thermal imaging solutions, thus overall boosting the application of infrared thermal imaging technology in more areas and empowering various industries.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar