Why Should Boost Electricity Inspection Efficiency by Utilizing Thermal Imaging

Electricity is the lifeblood of our modern world, powering our homes, industries, and gadgets. Ensuring its safety and reliability is paramount. Traditional methods of inspecting electrical systems have their limitations, often requiring time-consuming, manual processes that may overlook potential hazards. But fear not! There's a superhero in the world of electrical inspections, and it goes by the name of "Thermal Imaging."

Understanding the Importance of Electrical Inspections

Before we dive into the superhero's powers, let's understand why electrical inspections are so crucial. Imagine the havoc a faulty electrical system could wreak! Electrical fires, power outages, and even electrocution are all potential dangers lurking in the shadows. Electrical inspections are the caped crusaders that protect us from these disasters.

Challenges in Traditional Inspections

However, our trusty caped crusaders have faced challenges in the past. Traditional inspections often involve inspectors painstakingly examining electrical components one by one, hoping to spot anomalies. This process can be time-consuming, and there's always a risk of missing subtle warning signs.

Enter Thermal Imaging

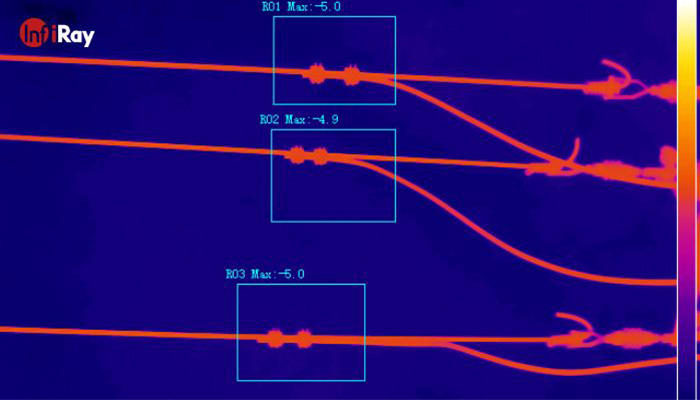

Now, it's time to introduce our superhero, Thermal Imager. Armed with specialized cameras, thermal imaging technology detects temperature variations within electrical systems. Think of it as X-ray vision for your electrical wiring! Here's why it's the ultimate sidekick for electrical inspections:

1. Detecting Hotspots and Abnormalities

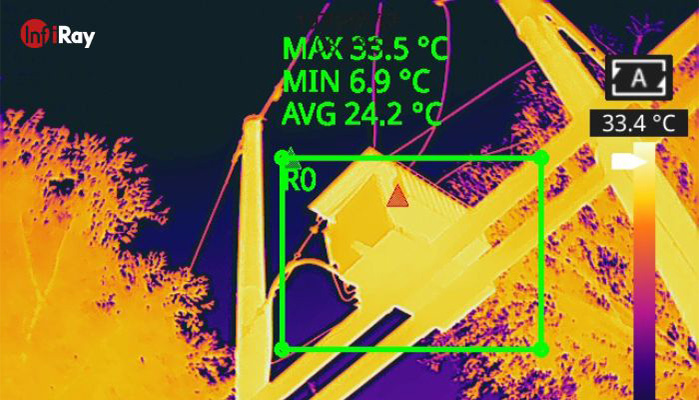

Thermal imaging can identify hotspots and abnormalities in electrical systems with remarkable precision. Hotspots are areas where electrical connections are overheating, often a precursor to equipment failure or fires. With a thermal camera, these hotspots are easily visible, allowing for timely intervention.

2. Non-Invasive Inspections

Unlike traditional methods that require dismantling equipment for inspection, thermal imager is non-invasive. It can inspect electrical systems without disrupting operations, minimizing downtime.

3. Real-Time Data Capture

Thermal imaging provides real-time data, allowing inspectors to monitor temperature variations as they happen. This instantaneous feedback empowers inspectors to make informed decisions swiftly.

Efficiency Improvement through Thermal Imaging

So, how does our superhero, Thermal Imaging, improve the efficiency of electrical inspections?

1. Rapid Fault Detection

The thermal camera's ability to spot hotspots means that potential issues are detected early. This early intervention prevents major failures, reducing costly repairs and downtime.

2. Reduction in Downtime

Fewer unexpected equipment shutdowns mean less downtime for businesses. By scheduling maintenance based on thermal imaging findings, organizations can optimize their operations and save money.

3. Enhanced Safety

Inspectors no longer need to risk their safety by physically inspecting hazardous electrical equipment. Thermal imager keeps them out of harm's way, preventing electrical accidents and fires.

Cost Savings

The financial benefits of adopting thermal imaging are impressive. Here are some examples:

1. Industrial Applications

In industries like manufacturing, where downtime can cost thousands of dollars per hour, thermal cameras can result in substantial savings. Predictive maintenance based on thermal data can prevent unplanned shutdowns and production losses.

2. Residential and Commercial Use

For homeowners and businesses, avoiding electrical fires and sudden outages can save both property and money. Early detection through thermal cameras mean avoiding costly emergency repairs.

Investing in thermal camera equipment and training might seem daunting at first, but the return on investment is substantial. The cost savings, increased efficiency, and improved safety quickly justify the initial expenditure.

Future Trends in Thermal Imaging

1. Advances in Technology: Thermal imaging technology keeps getting better. Higher resolutions, improved sensitivity, and greater affordability are on the horizon.

2. Integration with IoT: Thermal imager is becoming part of the Internet of Things (IoT) ecosystem. This integration allows for even more intelligent and automated monitoring of electrical systems.

3. Emerging Applications: Beyond electrical inspections, the thermal camera is finding new applications in fields like healthcare, agriculture, and security.

In the world of electrical inspections, thermal imaging is the hero we need. It's efficient, cost-effective, and enhances safety. By embracing this technology, we can ensure that our electrical systems remain reliable, preventing disasters before they strike.