Thermal Imaging Tips for Early Fault Detection in Electronics

In the fast-paced world of electronics, early fault detection is crucial to prevent costly downtime, equipment failures, and potential safety hazards. One powerful tool that has emerged as a game-changer in this field is thermal imaging. So how to effectively use thermal imager for early fault detection in electronics? We can explore today’s blog to get the answer.

Understanding the Basics

A. What is Thermal Imaging?

Thermal imaging, also known as infrared thermography, is a non-contact technology that captures the temperature variations of objects and displays them as colorful thermal images. These images, called thermograms, enable technicians and engineers to identify anomalies and pinpoint potential issues in electronic equipment.

B. The Importance of Temperature Variations

In electronics, temperature variations can be indicative of problems such as loose connections, damaged components, or overloaded circuits. By detecting these temperature anomalies early on, you can address issues before they escalate into critical failures. Find powerful thermal cameras that can detect early electronic faults here.

Benefits of Thermal Imaging in Electronics

1. Preventing Costly Equipment Failures

Thermal imaging allows you to identify overheating components or connections that may lead to equipment failures. By addressing these issues proactively, you can avoid expensive repairs or replacements.

2. Minimizing Downtime

Scheduled maintenance can be disruptive, leading to downtime that impacts productivity. Thermal camera lets you plan maintenance when it's needed, reducing unexpected and lengthy equipment downtime.

3. Enhancing Safety for Personnel

Faulty electronics can sometimes pose safety risks, such as fire hazards or electrical shocks. Identifying these faults through thermal imaging ensures a safer working environment for personnel.

4. Reducing Maintenance Costs

With thermal imaging, you can target specific areas for maintenance instead of conducting blanket inspections. This focused approach saves time and resources, ultimately reducing maintenance costs.

Thermal Imaging Equipment

A. Types of Thermal Cameras: There are various types of thermal cameras available, including handheld, mounted, and mobile units. The choice depends on your specific application and budget.

B. Considerations for Selecting the Right Camera: When selecting a thermal camera, consider factors like temperature range, resolution, and sensitivity. Choose a camera that suits your specific needs and the type of electronics you'll be inspecting.

C. Accessories and Software: To enhance your thermal imaging capabilities, consider accessories like remote sensors and thermal analysis software. These tools can help you gather more accurate data and analyze it effectively.

Best Practices for Thermal Imaging in Electronics

A. Preparation Before Inspection

· Clean the equipment to ensure accurate readings.

· Conduct inspections during normal operations to capture real-world conditions.

B. Proper Camera Settings

· Adjust the temperature range to capture the relevant temperature variations.

· Set the emissivity correctly for accurate measurements.

· Choose an appropriate thermal image resolution for your needs.

C. Image Acquisition Techniques

· Use systematic scanning patterns to cover all areas.

· Focus on critical components and areas with historical issues.

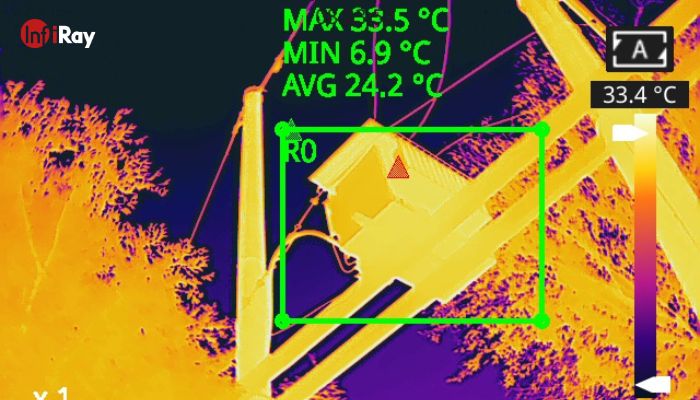

D. Interpreting Thermal Images

· Identify hotspots that indicate potential problems.

· Understand temperature gradients to assess the severity of an issue.

· Look for anomalies and variations that deviate from the norm.

Let's take a look at a couple of real-world examples where thermal imagers played a pivotal role in early fault detection in electronics.

1. Data Center Cooling Systems

In a data center, thermal imaging cameras were used to identify overheating server racks. By addressing the cooling system's inefficiencies promptly, they prevented potential data loss and hardware damage. Extend Reading: InfiRay Temperature Monitoring Solution with Infrared Temperature Measurement Thermal Cameras for Data Center Power Distribution Machine Rooms.

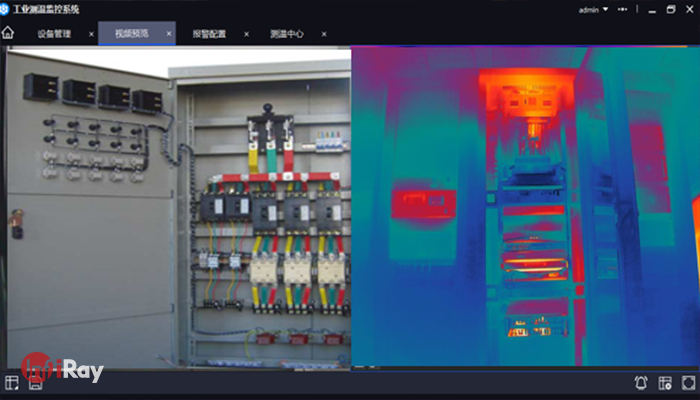

2. Electrical Panels

A manufacturing facility used thermal cameras to inspect electrical panels. They discovered loose connections that were generating excess heat. Addressing these issues proactively prevented costly production delays.

The thermal imager is a valuable asset for early fault detection in electronics. By understanding its basics, selecting the right equipment, and following best practices, you can harness its power to prevent costly equipment failures, reduce downtime, enhance safety, and cut maintenance costs in your electronic systems.

Incorporate thermal imaging into your maintenance strategy and stay ahead of potential issues before they become critical.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar