InfiRay Temperature Monitoring Solution with Infrared Temperature Measurement Thermal Cameras for Data Center Power Distribution Machine Rooms

As the infrastructure for the intelligent economy, big data centers are the core places for informatization. Fire safety is the top priority for ensuring the safe operation of data centers.

Pain Points of Fire Safety Maintenance in Big Data Centers

Currently, data centers mainly rely on traditional visible-light and smoke sensors to monitor the fire safety of devices in machine rooms. These sensors only work after smoke and fire have appeared and are incapable of early perception of temperature changes for prevention in advance.

The temperature of cabinet electrical devices is mainly monitored through contact measurement using thermocouples or other temperature sensors. This approach can only monitor individual points. It only archives this single function and is incapable of visual temperature monitoring of the whole surface.

Traditional patrol inspection is inefficient and may have problems such as omission and not finding abnormalities. The entry of patrol inspection data is inefficient and data upload reliability cannot be ensured.

Main Applications of Infrared Temperature Measurement Thermal Cameras

Monitoring of Cabinet Temperature and Machine Room Fire

The AT Fixed-Focus Infrared Temperature Measurement Thermal Camera is deployed for 24/7 full-coverage monitoring of the real-time temperature of data center power distribution machine rooms.

Videos and images with temperature data are uploaded to the monitoring back-office in real-time. The presence of abnormal temperatures in machine rooms will trigger audio and pop-up alarms at the back-office and fire alarm devices such that hazards are discovered and resolved timely.

Temperature Monitoring of Cabinet Electrical Devices

The AT20 Online Dual-Spectrum Infrared Temperature Measurement Thermal Camera features a compact size and PoE supply mode. It is deployed inside important electrical cabinets in data center machine rooms for all-weather uninterrupted temperature monitoring of key points, such as electrical contact points and connectors.

The thermal camera timely pushes alarm messages about abnormal connector heating due to overload and poor contact with back-office staff. This enables back-office staff to check and troubleshoot problems in cabinets.

Patrol Inspections of Data Center Power Distribution Machine Rooms

The C200, P200, and M600F Temperature Measurement Thermal Cameras can be utilized for frontline patrol inspections, inspections in small spaces, and professional problem diagnosis. They are practical tools to patrol inspection engineers and safeguard the safe operation of devices in data centers.

Thermal cameras provide intuitive temperature information of switchboards, switch boxes, circuit breakers, contactors, fuses, and cables. Photos taken on-site can be further analyzed by measured temperature analysis software to generate data reports to facilitate troubleshooting by engineers.

Unique Advantages of InfiRay Infrared Temperature Measurement Thermal Cameras

Remote, Non-Contact Measurement and No Need to Change The Target's Structure

Non-contact temperature measurement is achieved. The hottest spot on the screen or area is automatically captured to make problems intuitively visible and allow accurate problem locating. This helps engineers ascertain the root causes of faults in a reliable, precise manner, thereby finding a solution quickly.

Automatic Temperature Data Collection and Curve Generation

Real-time data reading enables intuitive monitoring of the detection process and automatic temperature detection. When used together with client software, the cameras allow the temperature data collection from targets, making it easy for operators to intuitively analyze the temperature trends of contact points in electrical cabinets and cabinet surfaces.

Alarm Function and Messages of Abnormality Alarms

The abnormal temperature range is set and the heat generated during the temperature rise of the cabinet surface and electrical devices in machine rooms is monitored. Temperature reaching the set range triggers alarms so that staff will be notified and take control measures.

Secondary development support for customers' unique advantages

A secondary development SDK is provided to support users, empowering them to form unique advantages. Alarm messages can be pushed through the IO port, serial port, or other various methods to assist customers in the action linkage and development of automation devices.

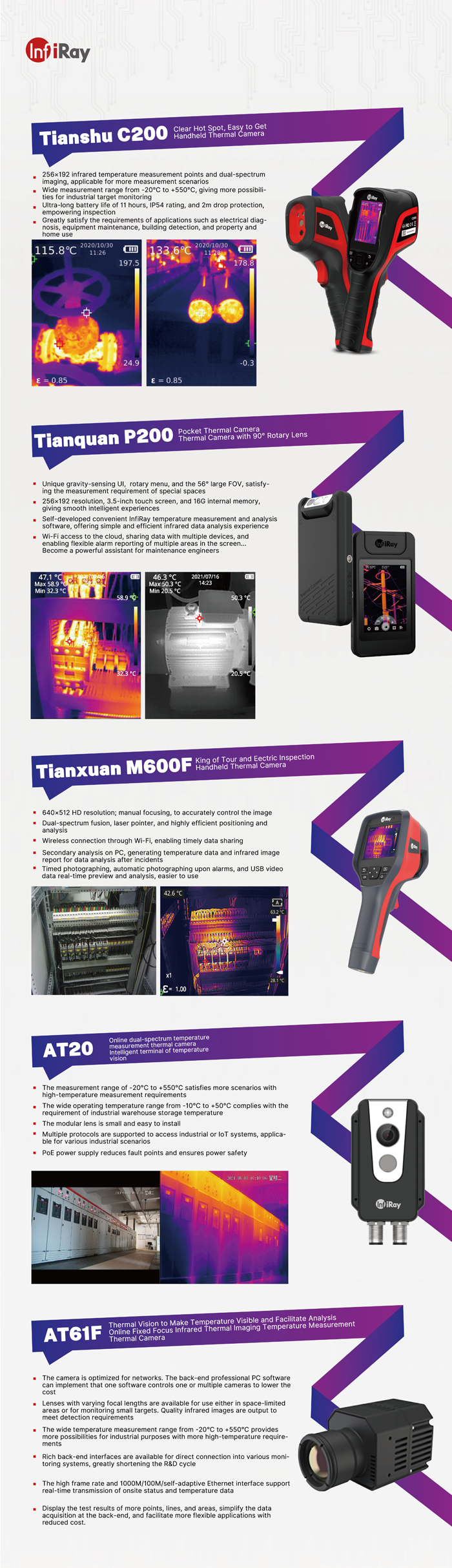

Recommended Models

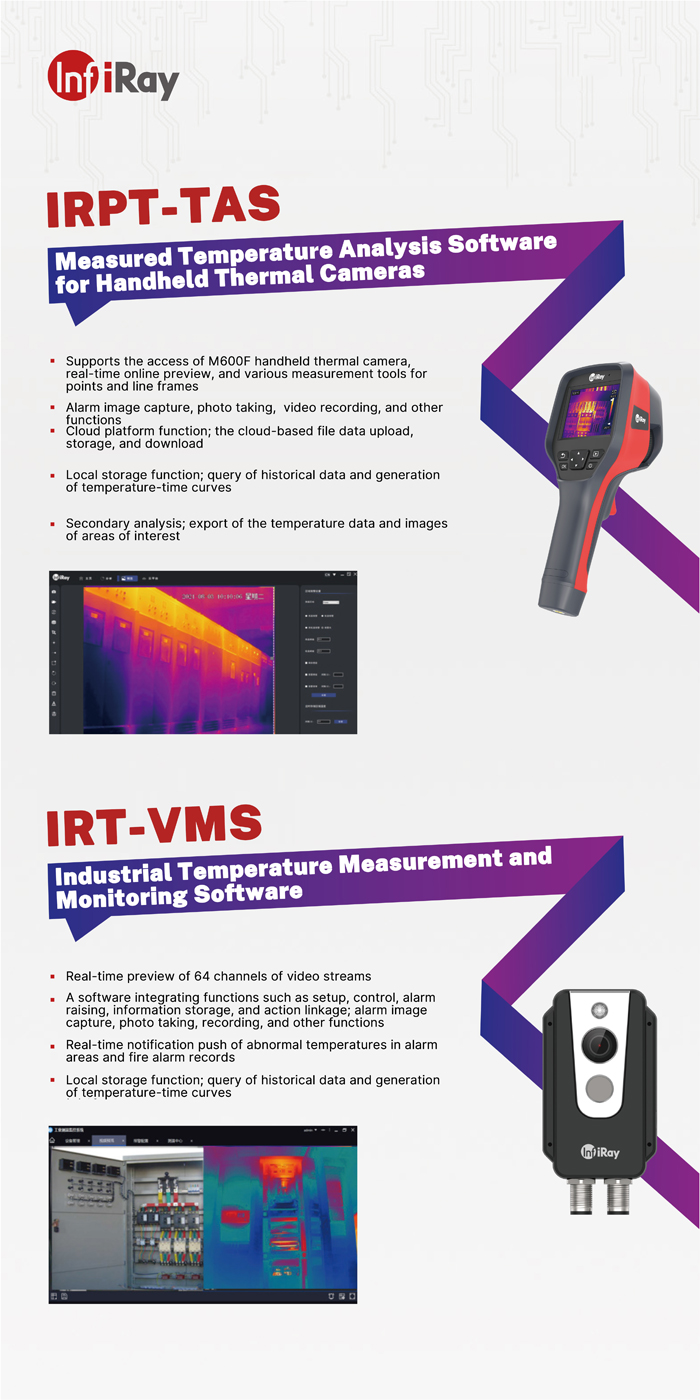

Recommended System Software

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar