Application of InfiRay Thermal Cameras in Optical Fiber Laser Inspection

Currently, the optical fiber laser has become the mainstream development direction and main force of laser industry applications. Temperature control directly affects the laser quality and service life. Thermal cameras can provide smart, high-precision, and non-contact temperature measures.

rement solutions, achieving high-efficiency testing of optical fiber lasers.

Application Example:

Optical fibers absorb part of the laser energy and cause temperature rise. A too high temperature will accelerate the aging process, and the aged optical fiber, in turn, accelerates the temperature rise, creating a vicious circle. This hampers the reliability and service life of the laser, and therefore thermal cameras are needed to measure the entire optical fiber, especially the temperature at the fusion splices.

A company in Shenzhen city is faced with the problem that the small temperature difference between the optical fiber backplane and the optical fiber makes it difficult to accurately locate the optical fiber. The company needs a solution and has the following requirement:

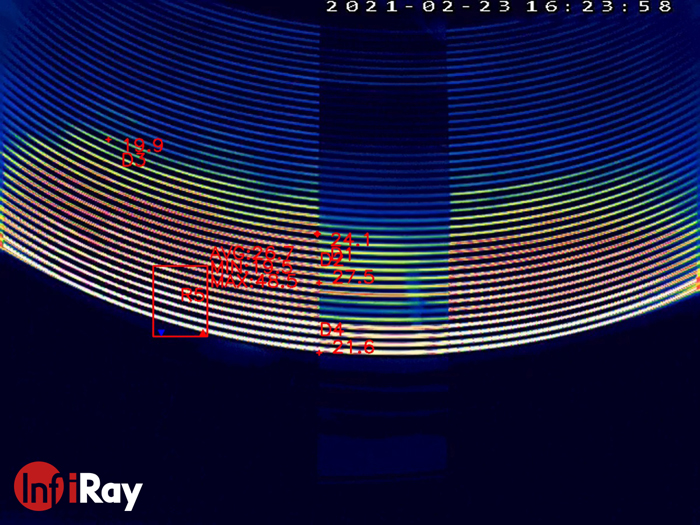

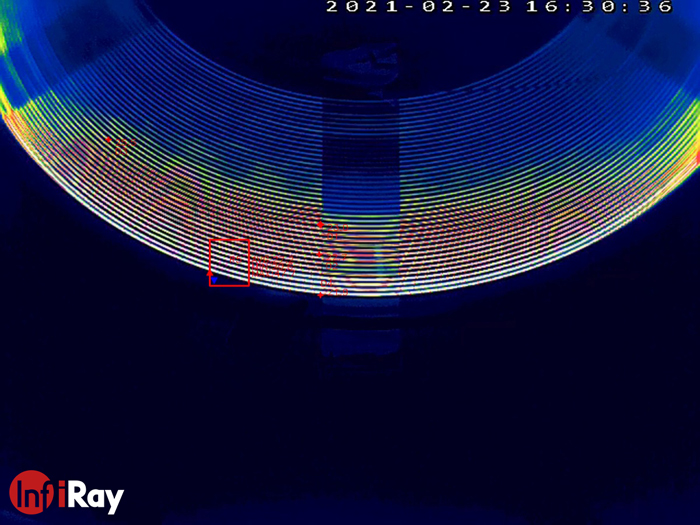

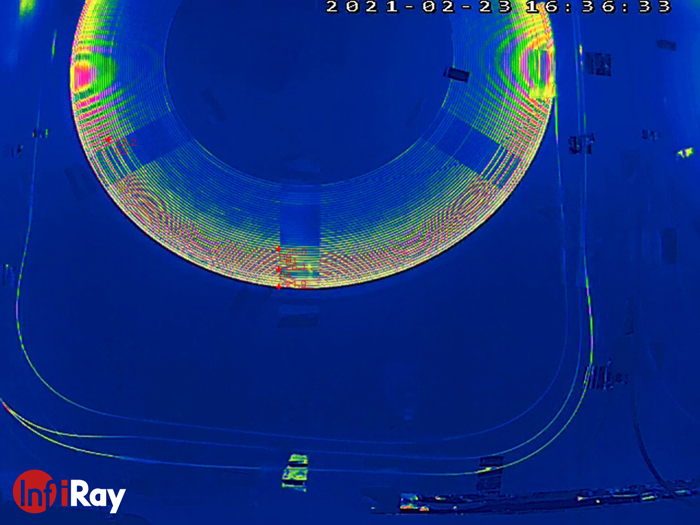

①The high-power laser (6.0KW, 12.0KW, 15.0KW, and 20.0KW) is turned on in a step fashion, from 15% to 30% to 50% to 80% and to 100%. In each step, the pump surface and YB optical fiber, nodes, and components must be examined to determine whether light leaks and whether the temperature is within the specified range. The laser should be examined in 100% power to see whether the standards are met.

②Temperature measurement should be implemented in different temperature areas, and alarms should be triggered when the temperature is exceeded in the area.

③The devices are controlled by PLC programs to implement automatic measurement of different locations on the optical fiber plane.

InfiRay studies the customer's requirements, investigates the use scenario, and then uses the AT61 thermal camera for temperature monitoring. The automatic rail is installed for automatic measurement in the X and Y directions, The solution satisfies all requirements of the customer.

Solution Strengths:

①Thermal cameras provide non-contact online temperature measurement and do not affect the objects to be measured. They can measure all temperature points of the image. The hottest point on the entire screen or the area is automatically captured for users to directly see the problem and efficiently locate problems without omission.

②Thermal cameras can be used alone or connect a PC and record full radiometric videos, providing the heat spreading path and temperature rise curves for R&D analysis;

③Thermal cameras support emissivity settings in different areas. Different emissivity settings can be implemented for different measured materials in a screen for more accurate temperature measurement;

④Thermal cameras support triggering through the temperature threshold, time, and duration, to implement automatic data collection and improve working efficiency.

As the leading manufacturer of uncooled IRFPA, InfiRay will leverage its cutting-edge technology and mass production capabilities to present its infrared camera series with a smaller size, lower power consumption, higher performance, and lower cost, as well as professional infrared thermal imaging solutions, thus overall boosting the application of infrared thermal imaging technology in more areas and empowering various industries.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar