Why Thermal Cameras Ensure Safe Industrial Work Environments?

Industrial work environments are hotbeds of activity, quite literally sometimes. With heavy machinery, electrical equipment, and various processes at play, ensuring safety becomes paramount. This is where thermal cameras come into the picture. In this blog, we'll dive into how thermal imaging cameras are changing the game when it comes to safety in industrial workplaces.

What is A Thermal Imaging Camera

Thermal cameras are like the superheroes of the tech world – they see what the naked eye can't. These cameras work by detecting infrared radiation, which is emitted by all objects with a temperature above absolute zero. They then translate this radiation into colorful images, with different colors representing different temperatures. Think of them as the X-ray vision goggles for temperature.

The Role of Thermal Cameras in Industrial Safety

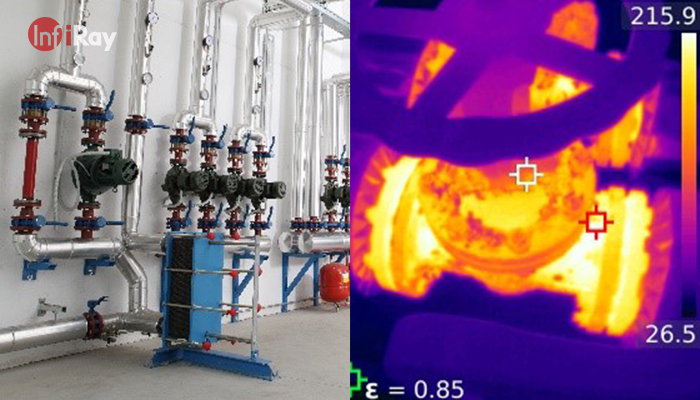

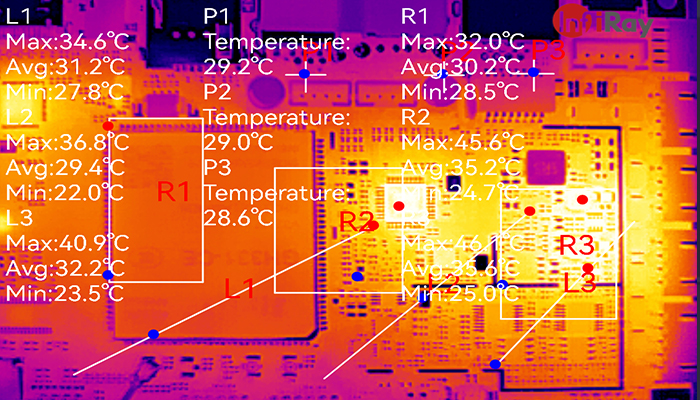

1. Early Detection of Temperature Anomalies

Imagine you're in a factory filled with complex machinery. How do you know if one of those machines is overheating? This is where thermal cameras shine. They can identify hotspots and detect overheating machinery long before it becomes a safety hazard.

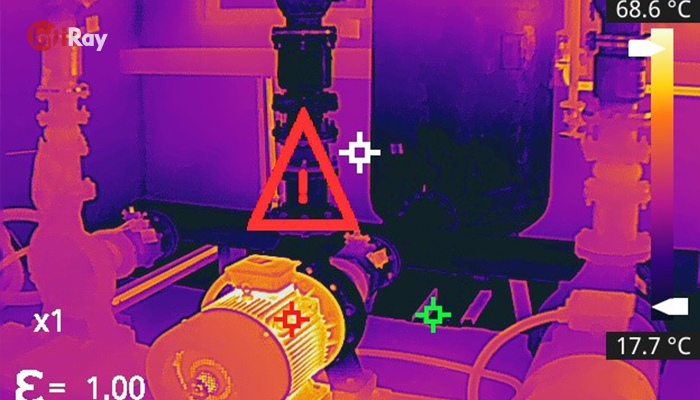

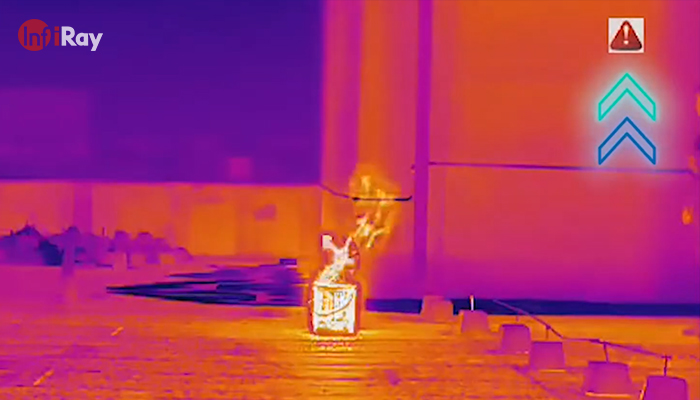

2. Prevention of Fires and Explosions

Fires and explosions are nightmares in industrial settings. Thermal imaging cameras can be your first line of defense. By monitoring electrical equipment and detecting gas leaks, they can prevent potential disasters from happening. It's like having a fire-breathing dragon detector, but much safer!

3. Ensuring Personnel Safety

In the era of pandemics, ensuring the health of workers is paramount. Thermal cameras can screen for fever by measuring body temperature from a distance. Also, in low-visibility conditions, such as smoke or darkness, these cameras can track personnel and guide them to safety. They're like the guardian angels of industrial workers.

Advantages of Using Thermal Cameras

Now that we've taken a deeper dive into the world of thermal cameras and their applications in industrial safety, let's shine a spotlight on the many compelling advantages they bring to the table. Think of these advantages as the superpowers that make thermal imaging cameras the heroes of workplace safety:

1. Non-contact and Non-invasive Wonder

Picture this: you're in a factory filled with machines and equipment that could be searing hot or laden with potentially harmful substances. Thermal cameras swoop in as your safety superheroes. Why? Because they can monitor all of this from a safe distance without ever making physical contact. In an industrial world where 'keep your distance' is often a golden rule, these cameras are a game-changer. Workers get to stay out of harm's way while the cameras do the risky business of monitoring.

2. Real-time Vigilance

When it comes to safety, timing is crucial. Thermal cameras are like lightning-fast sentinels. They provide real-time monitoring, immediately capturing and displaying temperature variations. This super-quick response allows for on-the-spot action when something's amiss. Whether it's a sudden temperature spike or a gradual change, thermal imaging is the ever-watchful guardian, ready to leap into action at a moment's notice.

3. 24/7 Unyielding Watchfulness

Unlike humans who need to catch some Z's, thermal cameras don't sleep, nap, or take coffee breaks. They're the unsung heroes working around the clock, ensuring unbroken safety and surveillance. This round-the-clock vigilance is particularly crucial in industries that never rest, like manufacturing plants or energy facilities. Whether it's high noon or the dead of night, thermal imaging stands guard.

4. Precision and Reliability Beyond Compare

When it comes to temperature measurement, thermal cameras are the Jedi Knights of precision. They can detect temperature variations as minuscule as 0.1°C, making them top-tier in accuracy. This level of precision ensures that false alarms are few and far between. You won't find these cameras crying wolf; they spot the real deal every time.

5. Seamless Integration with Safety Squad

In our hyper-connected world, teamwork is essential. Thermal cameras understand this and can flawlessly join forces with other safety systems. They sync up with alarms and automation systems. When thermal imaging detects a temperature hiccup, it can sound the alarm, and alert operators. This teamwork ensures that safety is a cohesive effort, leaving no room for gaps.

In the ever-evolving landscape of industrial workplaces, safety remains paramount. Thermal cameras are proving to be invaluable tools in preventing accidents, fires, and health-related issues. They are the silent protectors, working tirelessly to keep industrial workers safe.

So, the next time you step into a manufacturing facility, remember that those unassuming cameras on the walls might just be the heroes ensuring everyone goes home safely.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar