The Power of Thermal Cameras in Preventive Maintenance: Saving Time, Money, and Lives

Preventive maintenance plays a crucial role in ensuring the reliability and longevity of equipment, machinery, and electrical systems. It involves regular inspections and maintenance activities to identify and address potential issues before they escalate into costly failures. One technology that has revolutionized preventive maintenance is the thermal camera. With its ability to detect and visualize heat patterns, thermal cameras have become invaluable tools for identifying problems that are invisible to the naked eye.

What is Preventive Maintenance?

Preventive maintenance refers to a proactive approach to maintenance, which involves regularly scheduled inspections, servicing, and repairs. Its primary goal is to prevent equipment failure, minimize downtime, and extend the lifespan of assets. Preventive maintenance helps avoid costly breakdowns and ensures optimal performance by identifying and resolving issues early on.

How do Thermal Cameras Help in Preventive Maintenance?

Thermal cameras, also known as infrared cameras or thermographic cameras, are devices capable of capturing and visualizing thermal energy emitted by objects. They create detailed images called thermograms, which represent the variations in temperature across a surface. By using thermal imaging cameras, maintenance personnel can identify abnormal heat patterns, hotspots, or temperature anomalies that may indicate underlying issues. Extended Reading: Everything You Need to Know about Thermal Cameras.

1. Detecting Electrical Problems

Electrical problems, such as loose connections, overloaded circuits, or faulty components, can lead to equipment malfunctions, power outages, or even fires. Detecting these issues early is critical to ensure the safety and reliability of electrical systems. Thermal cameras excel in identifying such problems by pinpointing areas of excessive heat. During an inspection, a thermographic camera can scan electrical panels, breakers, and connections to identify potential trouble spots. The heat signatures captured by the camera reveal abnormal temperature rises, indicating loose or corroded connections. This early detection allows maintenance teams to address the issues promptly, preventing equipment damage and potential hazards.

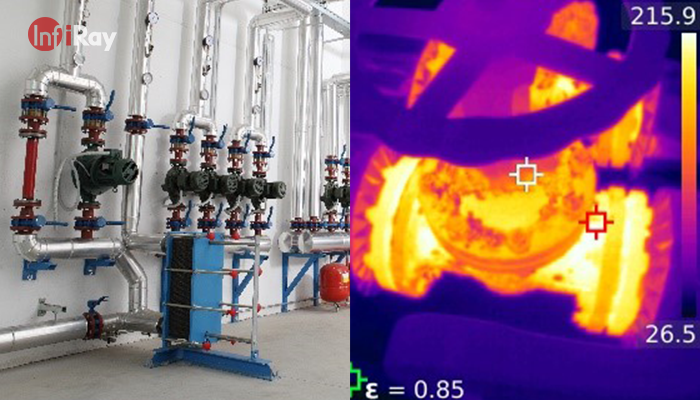

2. Monitoring Mechanical Systems

Thermal cameras are also highly effective in monitoring mechanical systems, such as motors, bearings, and pumps. By detecting temperature variations, they can identify potential failures or inefficiencies caused by friction, misalignment, or inadequate lubrication. During a mechanical inspection, thermal imaging can quickly scan the components and identify any hotspots or temperature variations. For example, an overheating bearing may indicate impending failure or insufficient lubrication. By detecting such issues early on, maintenance personnel can schedule repairs or lubrication tasks, avoiding unexpected breakdowns and optimizing equipment performance. Click to Check Why Can Thermal Cameras Help Check Your Home's Insulation.

3. Inspecting Insulation and Energy Loss

Thermal cameras are instrumental in assessing insulation integrity and identifying energy loss points in buildings and industrial facilities. By visualizing heat patterns, they can identify areas of inadequate insulation, air leaks, or energy inefficiencies. In a building inspection, they can identify heat loss through windows, doors, or poorly insulated walls. By pinpointing these areas, facility managers can take corrective measures to improve energy efficiency, reduce heating and cooling costs, and create more comfortable environments.

What are the Benefits of Using Thermal Cameras in Preventive Maintenance?

The use of thermal imaging cameras in preventive maintenance offers several key benefits:

Early Detection: Thermal cameras can identify potential issues before they become critical failures, enabling proactive maintenance and minimizing downtime.

Cost Savings: By addressing problems early on, they help prevent costly breakdowns, reduce repair expenses, and extend the lifespan of the equipment.

Enhanced Safety: Identifying electrical issues or equipment malfunctions in advance helps mitigate safety risks, preventing accidents and potential injuries.

Time Efficiency: Thermographic cameras allow for faster inspections and troubleshooting compared to traditional methods, saving valuable time for maintenance teams.

Comprehensive Assessments: Thermal imaging cameras provide a holistic view of the system's health, detecting issues that may be invisible to the naked eye, resulting in more thorough inspections. Find thermal imaging cameras that can help you in prevention maintenance here.

By integrating thermal cameras into routine maintenance practices, companies can improve the reliability of their equipment, optimize performance, and prevent costly breakdowns. Let us embrace this powerful technology and unlock its full potential in safeguarding our assets and ensuring a safer and more efficient future.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar