Avoid Fire Risks: Thermal Imaging for Electrical Safety

Electrical safety is a paramount concern in various industries and everyday life. Electrical systems power our homes, businesses, and critical infrastructure, but they also pose potential fire risks if not properly maintained. This is where thermal imaging technology comes into play. In this blog, we will delve into the significance of using thermal cameras for preventing fire risks in electrical systems.

Understanding Fire Risks in Electrical Systems

Electrical fires are often caused by factors such as faulty wiring, overloaded circuits, or loose connections. These fires not only jeopardize the safety of individuals but also lead to significant property damage and business disruptions. To mitigate these risks, it's essential to proactively identify potential issues before they escalate into emergencies.

Basics of Thermal Imaging Technology

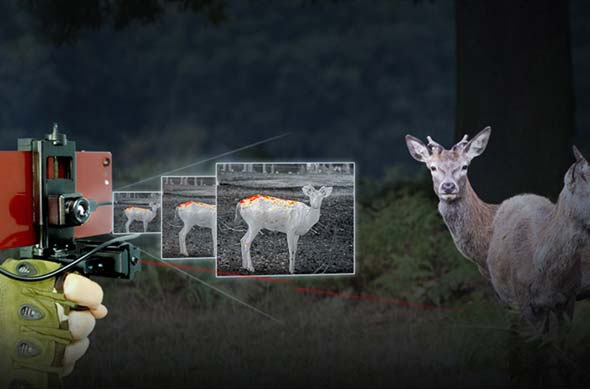

Thermal imaging is a non-invasive technology that allows us to visualize temperature variations in objects, surfaces, and environments. It works by capturing the infrared radiation emitted by objects and translating it into a visual representation called a thermogram. This technology is particularly effective in identifying abnormal temperature patterns, which can be indicative of underlying problems. Find Thermal Cameras That Can Be Used for Electrical Inspection Here.

Role of Thermal Imaging in Electrical Safety

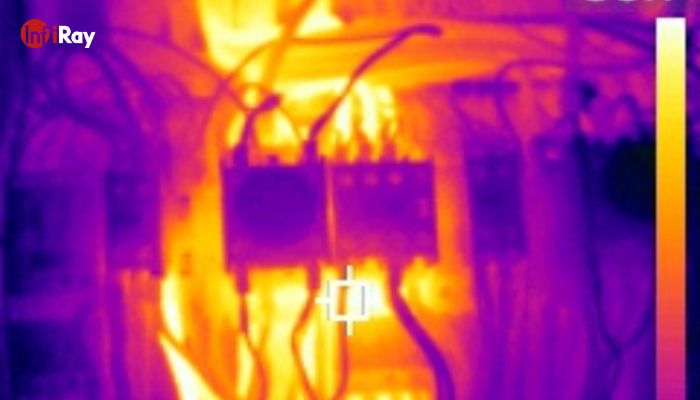

1. Detection of Hotspots: Hotspots, areas with elevated temperatures, are often early signs of impending electrical failures. Thermal cameras can quickly pinpoint these hotspots in electrical components, such as circuit breakers, switches, and connections, enabling timely intervention.

2. Early Issue Identification: Thermal imaging enables predictive maintenance, as it helps identify potential problems before they lead to system failures. By addressing issues at an early stage, businesses can reduce downtime and minimize repair costs.

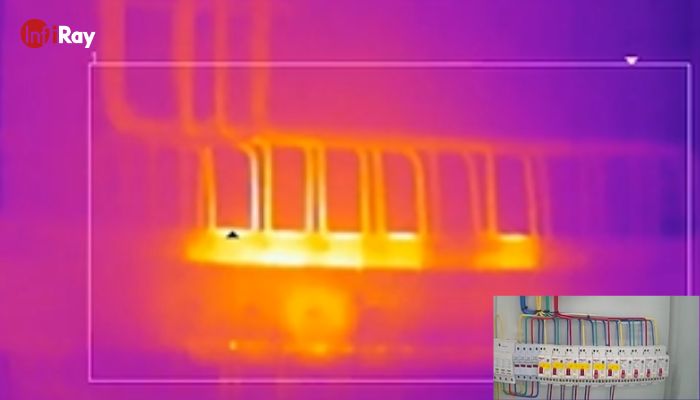

3. Non-Invasive Inspections: Unlike traditional methods that require physical contact with energized equipment, thermal imager allows technicians to conduct comprehensive inspections from a safe distance. This eliminates the need for shutting down systems, enhancing both safety and efficiency.

Implementing a Thermal Imaging Electrical Inspection Program

To harness the benefits of thermal imaging for electrical safety, organizations need to establish a structured inspection program.

1. Training and Certification: Skilled operators are crucial for accurate thermal imaging inspections. Operators should be trained to recognize thermal patterns associated with different types of faults.

2. Regular Inspection Schedule: Determine the frequency of inspections based on the criticality of the electrical systems. Integrating thermal cameras into routine maintenance routines ensures consistent monitoring.

3. Reporting and Analysis: Create detailed thermal reports that highlight identified issues and their severity. Prioritize actions based on the urgency of the problems detected.

Successful Applications of Thermal Imaging

Real-life examples highlight the effectiveness of thermal imager in preventing fire risks:

1. Overheating Components: In a manufacturing plant, thermal cameras identified overheating in a switchgear cabinet. Timely intervention prevented a potential electrical fire, saving both equipment and preventing production disruptions.

2. Comparative Analysis: A side-by-side comparison of thermal cameras with traditional methods revealed hidden issues missed by visual inspections. This underscored the superior accuracy of thermal imaging in identifying potential hazards. Extended reading: The Magic of Thermal Cameras: See Your Electrical System in a Whole New Way.

Overcoming Challenges and Limitations

While thermal imaging is a powerful tool, it's important to be aware of its limitations:

1. Environmental Factors: Ambient conditions, such as temperature and humidity, can influence thermal readings. Adjustments may be needed to account for these factors.

2. Surface Emissivity: The ability of an object to emit thermal radiation varies. Understanding surface emissivity is crucial for accurate temperature measurements.

Future Trends in Thermal Cameras for Electrical Safety

Advancements in thermal imaging technology are poised to revolutionize electrical safety:

1. Higher Resolution and Sensitivity: Ongoing research is enhancing the resolution and sensitivity of thermal cameras, enabling even more precise detection of temperature variations.

2. Integration with AI and Data Analytics: Combining thermal imagers with artificial intelligence and data analytics will enable automated fault detection and predictive maintenance.

Thermal imaging technology is transforming the landscape of electrical safety. By detecting hotspots, enabling early issue identification, and providing non-invasive inspections, the thermal camera plays a crucial role in preventing fire risks in electrical systems. Embracing this technology today not only safeguards lives and property but also ensures the smooth operation of critical infrastructure for years to come.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar