Safeguarding High-Power Electronics with Thermal Cameras

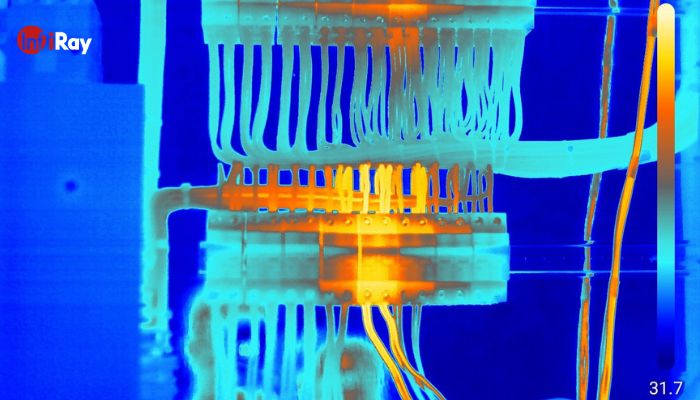

High-power electronics, found in industries ranging from manufacturing to scientific experiments, are susceptible to overheating, which can lead to catastrophic failures. In the dynamic landscape of high-power electronics, ensuring their reliability and longevity is paramount. Thermal cameras, equipped with advanced imaging technology, provide a cutting-edge solution to identify potential issues before they escalate. The use of thermal imaging cameras has emerged as a game-changer, offering a proactive approach to monitor and safeguard these critical components.

Understanding Thermal Monitoring

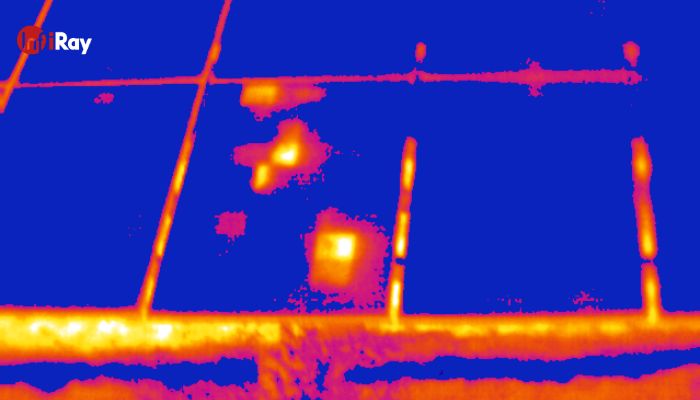

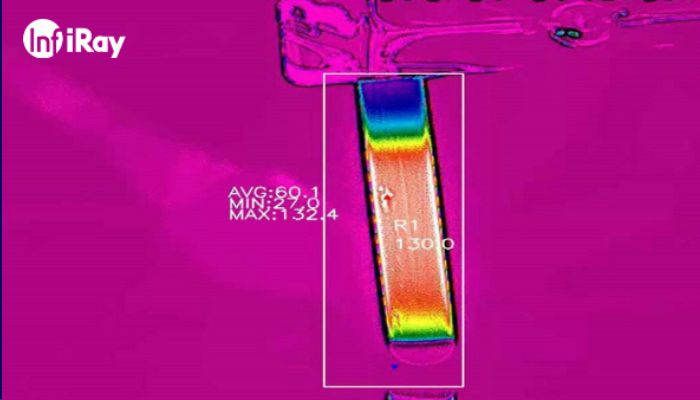

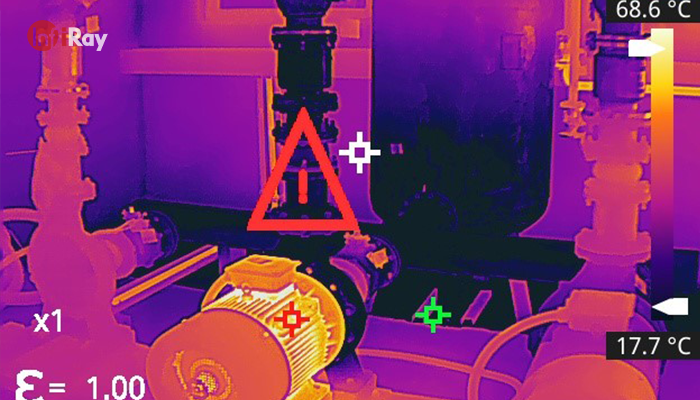

Thermal imaging technology operates on the principle of detecting infrared radiation, converting it into a visible image that represents the temperature variations of an object. In the context of high-power electronics, this translates to early detection of overheating, preventing costly downtimes and component failures. The real-time capabilities of thermal cameras make them indispensable for maintaining the overall reliability of electronic systems.

Applications in High-Power Electronics

1. Industrial Settings

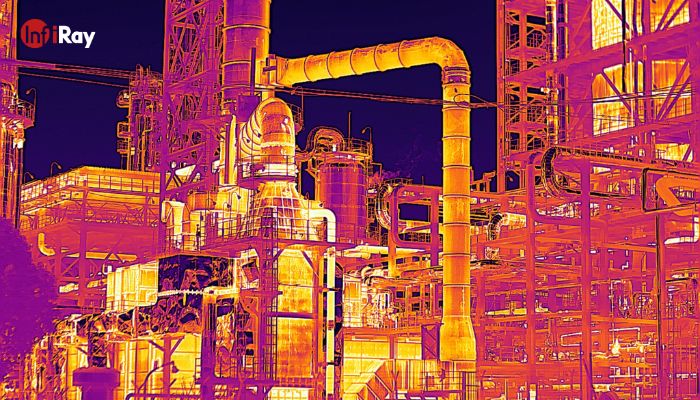

In the bustling realm of manufacturing plants and power stations, high-power electronics form the backbone of operations. Thermal imaging cameras play a pivotal role by providing continuous monitoring of equipment. Detecting temperature anomalies early on allows operators to intervene promptly, preventing potential damage to crucial components. This not only ensures the smooth operation of machinery but also minimizes downtime and maintenance costs.

2. Energy Sector

Within the energy sector, encompassing renewable energy installations and high-power transmission lines, the role of thermal cameras is crucial. These technologies aid in preventing overheating, ensuring the reliability of energy infrastructure. By identifying and addressing temperature fluctuations, this tech contributes to the longevity and efficiency of electronic systems in this critical sector.

3. Healthcare Technology

Beyond traditional sectors, the application of thermal cameras extends to healthcare technology. In medical facilities, high-power electronic devices, such as diagnostic equipment and imaging devices, are susceptible to overheating. They provide an added layer of security by monitoring temperatures, ensuring the continuous and reliable operation of critical healthcare systems.

4. Research Laboratories

In research and development settings, where cutting-edge technologies are developed, high-power electronics play a central role. Thermal cameras aid scientists and researchers in monitoring temperature variations, contributing to the precision and reliability of experiments and the overall functionality of advanced electronic systems.

Key Features of Thermal Cameras

Investing in high-quality thermal imagers provides several key benefits:

1. High Resolution

The detailed thermal imagery provided by high-resolution cameras allows for precise monitoring, ensuring that even minor temperature variations are identified.

2. Real-time Monitoring Capabilities

The real-time monitoring capabilities of thermal cameras enable immediate response to any detected anomalies, preventing potential damage to electronic systems.

3. Integration with IoT for Remote Monitoring

Thermal imaging cameras can be integrated into IoT systems, allowing for remote monitoring and management, providing flexibility and efficiency in overseeing high-power electronics.

4. Alarm Systems for Immediate Response

Equipped with alarm systems, thermal cameras alert operators to temperature irregularities, enabling swift action to prevent potential failures.

Real-world examples highlight the efficacy of thermal cameras in safeguarding high-power electronics. At a power plant, infrared cameras detected an ongoing problem with an electrical distribution unit that was much brighter than the others, so preventive maintenance was carried out to avoid costly downtime. These cases underscore the importance of proactive monitoring.

Importance of Regular Maintenance

Implementing thermal monitoring is not a one-time effort. Regular inspections and calibration are crucial to ensuring the continued accuracy of the system. Additionally, training personnel for efficient monitoring plays a vital role in maximizing the benefits of thermal imaging cameras.

Safeguarding high-power electronics is a multifaceted challenge that demands a proactive approach. Thermal cameras provide a reliable solution, offering real-time monitoring, early detection, and integration capabilities. By embracing these technologies and staying abreast of future trends, industries can ensure the resilience and longevity of their high-power electronic systems.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar