Professional Tips Using Thermal Cameras for Industrial Air Leak Detection

Industrial settings can be a labyrinth of pipes, ducts, and machinery, where hidden air leaks can wreak havoc on both energy efficiency and safety. Fortunately, modern technology has given us a superhero in the fight against these elusive culprits - thermal cameras! Today, we are going to explore professional tips on how to use thermal imaging cameras effectively for industrial air leak detection.

Understanding Industrial Air Leaks

Picture this: your industrial facility is like a ship sailing through the seas of production. But, instead of water, it's air that's constantly on the move, powering your operations. Now, imagine tiny holes in the ship's hull - those are air leaks. They may seem small, but they can cost you big in terms of wasted energy and compromised safety.

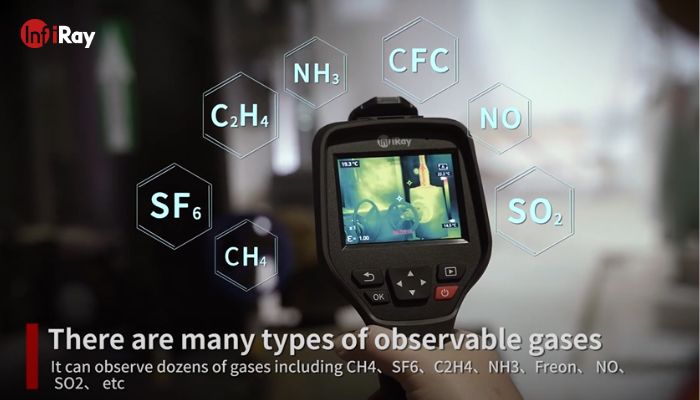

What is a Thermal Camera

Before we dive into the action, let's meet our hero: the thermal camera. These gadgets are like magic eyes that can see what our regular eyes can't. They work on the principle of detecting heat signatures. Every object emits infrared radiation, and thermal imaging cameras capture this radiation to create a temperature map, highlighting even the tiniest temperature differences.

Preparing for Air Leak Detection

Now, let's get ready for our air leak detection adventure. Safety first! Equip yourself and your team with the necessary safety gear like goggles, gloves, and, of course, the thermal camera. Ensure that your facility is well-lit to get accurate readings.

Using Thermal Cameras for Air Leak Detection

Here comes the exciting part - using the thermal camera. It's as easy as point-and-shoot. Start by scanning the areas you suspect may have air leaks. Pay close attention to joints, valves, and any equipment that might be potential culprits.

As you scan, you'll notice temperature variations on the camera's screen. Air leaks often show up as cooler or hotter spots compared to their surroundings. These cold or hot spots indicate where air is escaping, making them easy to spot.

Common Challenges and Solutions

Like any superhero, thermal cameras face challenges in their quest. Sometimes, environmental conditions like wind or extreme temperatures can affect the accuracy of your readings. Don't worry; there are solutions.

To combat wind interference, try using screens or barriers to create a still environment around the suspected area. In extreme temperatures, allow your thermal imaging to adjust to the conditions before starting your scan. These little adjustments can make a big difference.

Benefits of Using Thermal Cameras

Now, let's talk about why thermal imagers are the real MVPs in air leak detection. They not only help you locate leaks quickly but also save you money. By identifying and fixing air leaks promptly, you can improve energy efficiency and reduce your utility bills. Extended reading: Why Thermal Cameras Ensure Safe Industrial Work Environments?

Moreover, thermal imaging cameras are non-destructive. You won't need to tear down walls or dismantle equipment to find those pesky leaks. This not only saves you time but also prevents unnecessary damage to your facility.

Maintenance and Best Practices

Lastly, to keep your thermal camera in tip-top shape, follow these maintenance tips:

· Regularly clean the camera lens to ensure clear imaging.

· Store it in a protective case to prevent damage.

· Calibrate the camera as per the manufacturer's recommendations.

· Keep the battery charged and have spare batteries on hand for extended use.

In conclusion, using thermal cameras for industrial air leak detection is a game-changer. It's like having X-ray vision for your facility's hidden problems. By following these professional tips, you can identify and address air leaks efficiently, saving energy and money while ensuring a safer working environment.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar