Important Application of Thermal Cameras in Battery High-Temperature Aging Tests

"Aging" is an indispensable process and also a process with the highest risks in the battery production process.

The traditional visible-light monitoring cannot promptly detect the exceptional changes in lithium-ion batteries during the aging process. Usually, severe safety accidents have already occurred when the problem is discovered. Thermal cameras can promptly detect batteries with exceptional changes in the aging process, to implement pre-warnings and real-time online infrared monitoring in high-temperature aging workshops for lithium-ion batteries. Each preventive measure can be implemented before the fire, to effectively prevent fire and ensure manufacturing safety.

I. Main Application of Thermal Cameras in Battery High-Temperature Aging Tests

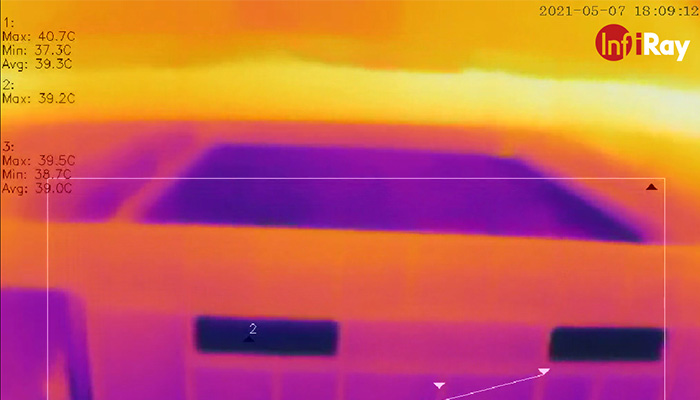

The thermal camera is installed on the stand of the stacking crane. As the stacking crane moves during daily operation, the camera monitors the temperature status of lithium-ion battery chips. The thermal camera transmits signals to the industrial temperature monitoring system on the PC through network cables for real-time thermal image display, temperature measurement, and pre-warning. This helps monitoring personnel to discover exceptions in the monitored area and implement remedies in advance accordingly. Alarm parameters are configured according to the temperature characteristics of the "aging" process for lithium-ion batteries, to provide pre-warning of exceptional temperature fluctuation of battery chips, preventing fire.

II. Unique Advantage of Thermal Cameras Applied in Battery High-Temperature Aging Tests

1. Thermal cameras feature high stability and reliability and can adapt to the special temperature environment of the high-temperature aging workshop

2. All-weather real-time temperature monitoring is implemented for the entire workshop, supporting display and analysis of temperature of a selected area in a video and image

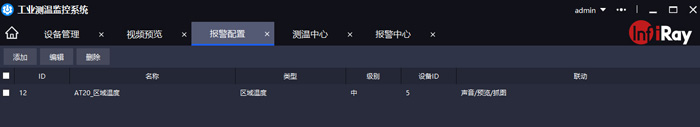

3. The alarm parameters can be configured based on the temperature characteristics of the monitored area, to achieve pre-warning of exceptional battery temperature fluctuation at an early stage

4. Multiple protocols are supported to access the industrial or IoT systems, extensively applied to scenarios such as device operation status safety monitoring and confined-space fire-prevention monitoring

III. Recommended Models

1. AT20 Thermal Camera

① Modular lenses, compact size, and easy installation; 56° FOV, to cover the entire temperature monitoring area

② Dual-spectrum fusion, with clear imaging, helping staff to locate the hottest point and promptly detect the battery chips with exceptions in the aging process

③ Automatic temperature report generation and monitored area temperature recording upon discovering temperature exceptions, for analysis and review in the future

2. AT31/61/61P Thermal Cameras

① PoE power supply, automatic focusing, to cover both far and near targets; electric lens position saving upon power-off

② Simultaneous output of the temperature stream data and image stream data, to promptly predict the fire and ensure test safety

③ Secondary development support to easily connect to the aging test workshop system

3. AT31F/61F Thermal Cameras

① Compact size for easy installation; multiple lenses to choose from, to satisfy various detection requirements

② 24-hour all-weather monitoring, supporting online monitoring and I/O alarm output for high temperature/low temperature/temperature rise in the area, to effectively prevent fire

③ Secondary development support, with good openness, integration, and scalability

IV. System Software

With the InfiRay IRT-VMS industrial temperature measurement and monitoring system, multiple devices can be networked to connect the software platform for image displaying. A maximum of 64 real-time images can be displayed for video preview, and palette selection, temperature measurement tool configuration, and alarm configuration are supported. The temperature data curve and report are automatically generated to effectively monitor the temperature changes of the battery chips in the warehouse.

V. How Can I Use a Thermal Camera to Produce a Thermal Image of Premium Quality?

Please refer to the following suggestions for using a thermal imager to produce a thermal image of premium quality:

1. Note that a few types of lithium-ion batteries are equipped with metal shells. During the inspection, the devices should be deployed to vertically monitor these batteries, avoiding onsite interference, and it is best to cover the battery with paint or tape

2. Select thermal imagers with high thermal sensitivity for scenarios with a small regional temperature difference

3. Select products or levels of proper measurement ranges for different scenes and temperature

4. Use automatic measurement first, and then enable the temperature width stretch function. Manually set the temperature width to the minimum and include the previously measured temperature range to enrich the image details

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar