What Advantages Do InfiRay Thermal Cameras Have in Monitoring Hazardous Waste Storage?

The hazardous waste warehouse temporarily stores and processes the hazardous wastes. Due to heat accumulated by spontaneous combustion, frictions, and pressures, spontaneous chemical reactions between wastes, and methane gathering, potential fire can be caused, severely endangering safe production.

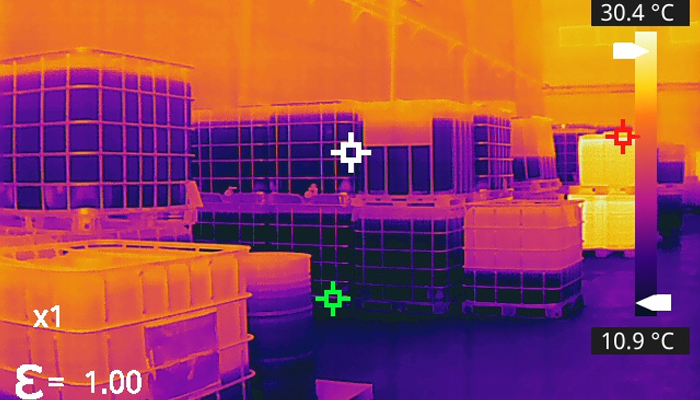

Traditional monitoring methods can hardly identify subtle leakage of wastes and the temperature changes caused by the chemical reaction of different wastes. Thermal cameras can monitor the temperature of hazardous waste warehouses in an all-weather manner, and linkage alarm of multiple devices is supported for processing the accident as there is a sign of it, effectively preventing the fire from happening.

I. Main Applications of Thermal Cameras in Monitoring Hazardous Waste Storage

1. Monitoring hazardous waste storage

Thermal cameras with hazardous chemical storage safety monitoring software are used for the fire prevention of hazardous wastes in the storage. Automatic online temperature measurement is implemented, with no manpower needed. Linkage alarms with multiple devices are supported, to produce real-time alarms of high-temperature points in the workshop, promptly preventing fire.

II. Unique Advantages of Thermal Cameras in Monitoring Hazardous Waste Storage

1. Easy to use: It is easy to install and use. Explosion-proof shells of multiple specifications are available to reduce the impact of the environment on the device service life.

2. Remote monitoring: Online remote monitoring and control enable networked operation of multiple devices through background software, thus reducing the cost of onsite personnel monitoring

3. Wide measurement range: The wide measurement range from -20°C to +550°C is supported, effectively adapting to the hazardous waste treatment and storage procedure in different environment

4. Professional software: Safety monitoring software for hazardous chemical storage is equipped, which is professional, and its functions can be customized in accordance with customer's requirements

5. Multi-level alarm: Linkage alarms are supported by the fire prevention module, which is connected to the multi-level alarm control box to provide the multi-level alarm signal. In this way, fire alarms are efficiently provided