Techniques for Using Thermal Imaging Cameras for Industrial Air Leak Detection That Only Professionals Know

The workplace may be a maze of pipelines, pipelines, and machines, with the potential for leakage of concealed air to damage the effectiveness and security of the system. Luckily, we've got a superhero to deal with those mysterious criminals -- thermal cameras! Today we will discuss how to use a thermographic camera to apply technical techniques for air-leakage tests in the industry.

Research on Understanding Industrial Air Leaks

Imagine this: your industry is like a boat on an ocean of manufacturing. But instead of water, it's the air that's constantly pushing you along. Think of little holes in the hull -- they're leakage of air. While they look tiny, they can be costly in terms of lost power and security.

What Does Thermal Camera Mean

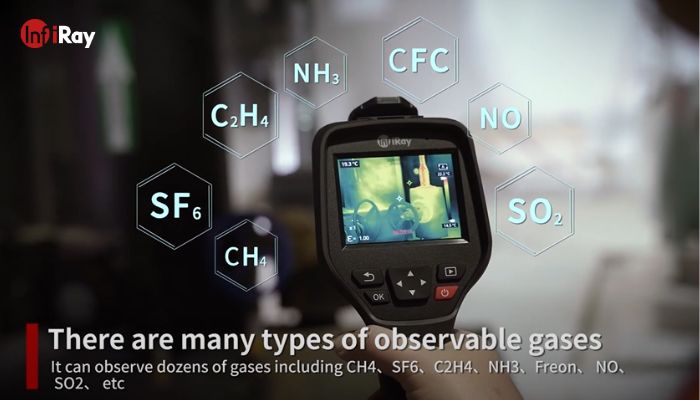

Before we begin, I'd like to introduce our main character: a thermal camera. This incredible device is like a magical eye, capable of seeing things that are not visible to the naked eye. Its function is to detect thermal signatures. Every object emits an infrared ray, which is captured by the camera and displayed on a thermograph. This allows even the slightest variation in temperature to be detected.

Air Leak Detection Preparation

So, we're going to prepare for the adventure of an air escape. Safety comes first! Ensure that you and your group wear the necessary protective equipment such as gloves, glasses, and thermal cameras. Make sure your equipment is well-lit so you can obtain precise measurements.

Air Leak Detection of Using Thermal Cameras

Now, there's an interesting bit to do -- with a thermal imaging camera. It's as simple as point and point. Begin by looking for any possible air leakage. Be on the lookout for potential causes, including joints, valves, and other devices.

When you're scanning for air leaks, you may notice a change in your camera's temperature. The air leakage is typically distinguishable by a colder or warmer area than its surroundings. The cool or warm spots indicate the location of the leaked air and can be easily identified.

Common Challenges Using Thermal Camera to Detect Air Leak

Like all superheroes, thermal cameras face challenges in their search. In some cases, weather conditions such as wind and high temperatures may interfere with the precision of your measurements. Do not be afraid, we have a solution.

To fight against wind disturbance, try to create a static atmosphere surrounding the suspicious zone with a screen or barrier. Before beginning the scan, allow your body to acclimate to high temperatures. Those small changes can be very significant.

Advantages of Using Thermal Cameras

Now, we're going to discuss how a thermal imaging device can be a true MVP for detecting gas leakage. Not only can they help you find leaks quickly, but they can also save you a lot of money by detecting and correcting air leaks early, which increases energy efficiency and reduces utility bills.

Furthermore, the thermographic camera is non-destructive. You don't have to knock down the wall or take apart the facilities to look for these annoying leaks. Not only will it save you time, but it will also avoid unwanted destruction of your equipment.

Conservation and Best Practices

Finally, to maintain the thermal camera in the best position, use the following maintenance tips:

- It is important to regularly clean the camera lens to ensure that the pictures taken are clear.

- Keep it in a protective box to avoid damage.

- Calibration of the camera as recommended by the manufacturer.

- Make sure that your battery is fully charged and that you have a backup battery ready for long periods of time.

To sum up, it's a game change to apply the thermal camera to the industry to detect the leakage of air. It's like you've got x-ray eyes on the underlying issues of your device. With the help of this expert technique, you will be able to detect and solve the problem of leakage effectively, which will reduce the amount of energy and cost involved in making the workplace more secure

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar