Avoid Catastrophic Failures with Thermal Cameras

High-power electronics are very prone to overheating and can lead to catastrophic failures. Ensuring their reliability and longevity is critical. Thermal imaging cameras can detect possible problems before they escalate. It has become a game changer, providing an active way to monitor and protect.

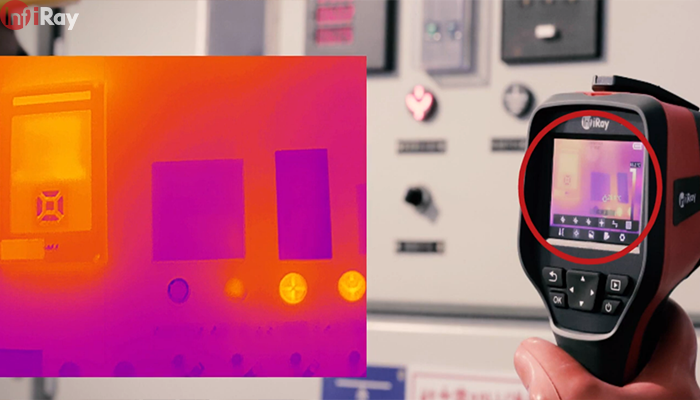

Understanding Thermal Imaging Monitoring

Thermal techniques can detect infrared radiation and turn them into visual images showing temperature changes. In high-power electronics, this means detecting excessive heat in time and avoiding expensive downtimes and parts faults.

Application of High-Power Electronics

1. Industrial Settings

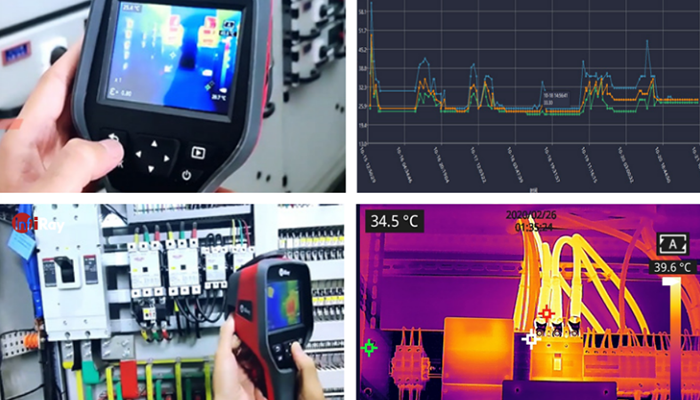

In the world of factories and power plants, high-power electronic equipment is the mainstay of business. Thermographic cameras are critical in their ability to continuously monitor devices. Early detection of the abnormal temperature will enable the operator to act quickly and avoid possible damage to critical parts. Not only does this guarantee that machines run smoothly, but it also reduces downtime and maintenance expenses.

2. The Energy Sector

In the field of power, which includes renewable and high-power transmission lines, the role of the thermal camera is essential. Such techniques help to avoid overheating and to make energy infrastructure more reliable. This technology makes it possible to maintain the durability and effectiveness of electrical systems in this key industry by detecting and dealing with temperature variations.

3. Healthcare Technology

In addition to the traditional industries, the use of thermal imaging products is also expanding into health care. High-power electronics like diagnostics and imaging equipment tend to be overheated. Through temperature monitoring, they give additional safety to ensure that key healthcare systems operate continuously and reliably.

4. The Research Laboratories

In R&D environments, where the most advanced techniques are being developed, high-power electronic devices are crucial. Thermal cameras help scientists and researchers detect temperature changes, helping to improve experimental accuracy and reliability as well as the overall performance of modern electronics.

Thermal Cameras' Key Features

Investment in high-quality thermal imaging offers several main advantages:

1. High Resolution

This makes it possible to keep track of even the smallest temperature changes.

2. The Real-time Monitoring Capabilities

The real-time surveillance ability of the thermal camera allows for an instant reaction to any abnormal event that is discovered, thus avoiding possible damage to the electrical system.

3. Integrating Remote Monitoring with Internet of Things

Thermographic cameras can be incorporated into the Internet of Things, enabling remote surveillance and administration, and offering flexible and efficient supervision of high-power electronics.

4. Immediate Response Alarm Systems

Equipped with an alert system, the thermal camera will alert the operator if there is a sudden temperature change, enabling it to take immediate action to prevent potential failures.

Efficacy of thermal cameras in protecting high-power electronics

Inside one of the power stations, infra-red cameras had discovered a continuing issue with one of the mains lights, which was far more brightly lit than the rest and had required preventative repairs to prevent expensive downtime. Such instances highlight the need for active surveillance.

Significance of Regular Maintenance

The implementation of thermal monitoring is not a one-off exercise. Periodic checks and calibration is essential to keep the system accurate. Furthermore, training staff for effective monitoring plays a crucial role in maximizing the benefits of thermal imaging cameras.

The protection of high-power electronic equipment is a huge challenge, requiring active action. Thermal cameras provide real-time surveillance, early detection, and integration. Adopting those techniques and keeping pace with the latest developments will enable them to make their high-power electronics more durable.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar