Important Application of Thermal Cameras in Battery Storage Monitoring

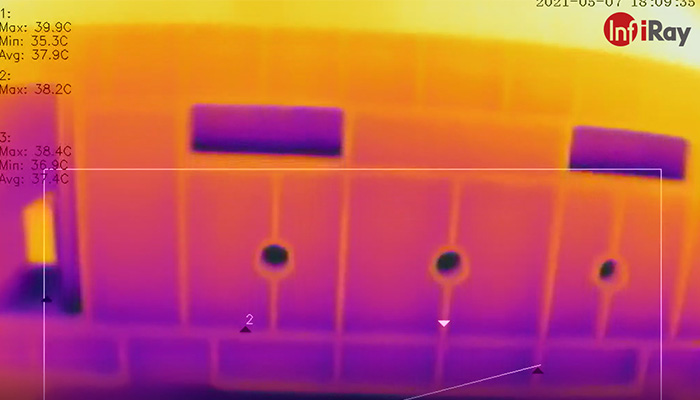

In recent years, the new energy vehicle industry is booming, creating enormous opportunities for the battery industry. Lithium-ion batteries have the same energy ratio and bearing capability in high power in smaller sizes compared with other batteries, making them the mainstream energy storage devices in the vehicle domain. Due to the activity of lithium ions, lithium-ion batteries in the warehouse are prone to short circuits, causing heat and ignition. The heating and ignition processes are extremely short, and common smoke sensors and temperature sensors can hardly discover the problem promptly. When the problem is discovered, major financial losses have already occurred, severely threatening life and financial safety. Thermal cameras can monitor the temperature distribution of battery packs in real time, to quickly and accurately locate the exception and hottest point, promptly trigger alarms, and link the fire-prevention system, effectively avoiding major fire and explosions.

I. Main Applications of Thermal Cameras in Battery Storage Monitoring

Monitoring the battery status and temperature changes in the warehouse: When the thermal camera detects temperature exceptions of the battery, it promptly generates pre-warning signals; the signal is transmitted through the alarm output port for sound and light alarm and fire-prevention linkage. Software is used to analyze whether there is fire, and determine whether to link the fire-prevention system. After the point of fire is confirmed, the fire alarm is sent to the local monitoring platform.

II. Unique Advantages of Thermal Cameras in Battery Storage Monitoring

1. All-weather real-time temperature monitoring is implemented for the entire battery warehouse, supporting display and analysis of temperature in a selected area of a video and image

2. The alarm parameters can be configured based on the temperature characteristics of the monitored area, to achieve pre-warning of exceptional battery temperature fluctuation at an early stage

3. Multiple protocols are supported to access the industrial or IoT systems, extensively applied to scenarios such as device operation status safety monitoring and confined-space fire-prevention monitoring