Application of Thermal Cameras in Monitoring Hazardous Waste Treatment

In a hazardous waste treatment center, hazardous waste is temporarily stored and then burned. Improper treatment will bring dangers such as fire and explosions. Causes of fire include spontaneous combustion, fabric debris contacting solvent, and lithium-ion batteries in the waste, severely endangering safe production. Traditional monitoring methods can only identify dangers on the surface. Thermal cameras can be deployed for all-weather hazardous waste monitoring to display the real-time temperature information of monitored objects and trigger linkage alarms of multiple devices. In this way, alarms can be triggered when the temperature drastically changes, to prevent the fire before happening.

I. Main Applications of Thermal Cameras in Monitoring Hazardous Waste Treatment

1. Temperature Monitoring for the Secondary Combustion Chamber

A secondary combustion chamber is the secondary combustion system installed to burn the exhaust gas from the rotary kiln. It can effectively remove organic substances and other hazardous gas that are not completely burned in the exhaust gas of the rotary kiln, ensuring that the exhaust gas does not cause pollution. With thermal cameras, temperature data can be monitored in real-time. Users can configure the temperature upload time interval, use software to process data and generate temperature curves, and determine the temperature change trends accordingly. This can effectively help to monitor and determine the burning process in the secondary combustion chamber, ensuring its safe operation.

2. Temperature Monitoring for the Waste Pit

The waste pit is used to temporarily store, mix, and prepare the waste to be burned. Various types of hazardous wastes with complicated characteristics are stored in the pit, and some wastes are usually combustible and reactive and fiercely burn with spontaneous combustion in the pit. Traditional visible-light fire alarm triggers can trigger alarms only after a fire breaks out in the pit. Once the fire has spread, it will severely damage life and property safety. Thermal cameras are used for comprehensive temperature monitoring, for staff to promptly get information about areas of exceptionally high temperature. Then staff can determine whether to conduct operations in advance or spray water for cooling down, preventing temperature rise and fire.

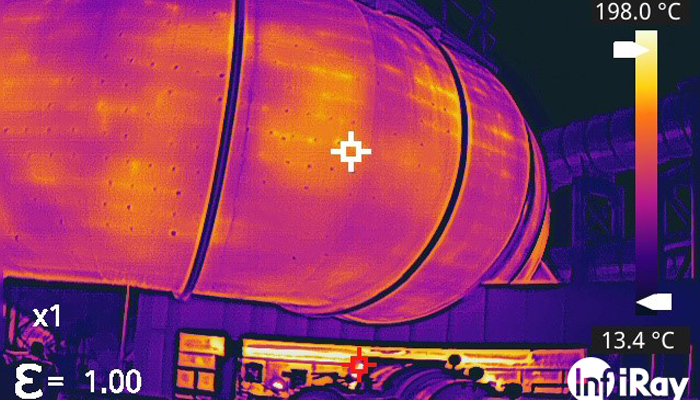

3. Temperature Monitoring of the Rotary Kiln

There are refractory materials of about 220mm thick inside of the rotary kiln, with a 20 to 30mm thick cover of steel plates. The refractory materials inside the rotary kiln will be eroded and even fall off. Consequently, the steel plate, exposed in the high-temperature environment, will be softened and even melted, severely threatening safe production. Thermal cameras are deployed for all-weather monitoring on the rotary kiln, for real-time display of temperature on the external shell of the rotary kiln. Therefore, staff can get to know the degree of refractory erosion inside the rotary kiln. Linkage alarm of multiple devices and configuration of multiple temperature measurement areas are supported, helping to take preventive measures to avoid rotary kiln penetration.

II. Unique Advantages of Thermal Cameras in Monitoring Hazardous Waste Treatment

1. Flexible selections of products with different lenses and resolutions enable users to easily handle different scenarios. Explosion-proof shell and PTZ offer flexible onsite installations.

2. Comprehensive temperature monitoring and division of multiple temperature measurement areas are supported, and users can also configure different temperature alarm thresholds for different types of wastes.

3. 7×24 hour continuous safety monitoring is supported for users to discover signs (heat) of spontaneous combustion in real-time and implement pre-warnings and alarm IO. Alarms will be triggered if a temperature exception occurs.

4. The temperature measurement and monitoring system can link the fire-prevention module, automatically triggering and controlling the fire-prevention system to handle potential risks in a safe and efficient manner.