Application of Thermal Cameras in the Railway Pantograph-OCS System Monitoring, to Assist Railway Transportation

The railway pantograph-OCS system provides power to electric locomotives, and the system quality and its operational status will directly affect the transportation capability and safety of the railway. Thermal cameras are vital in the railway pantograph-OCS system monitoring. Thermal cameras are installed on the roof of the locomotive to monitor the real-time temperature of the pantograph-OCS system and promptly record the high-temperature value and fault locations of the system, so that maintenance staff can repair the system in time and avoid power interruptions and transportation paralysis.

I. Main Applications of Thermal Cameras in Pantograph-OCS System Monitoring

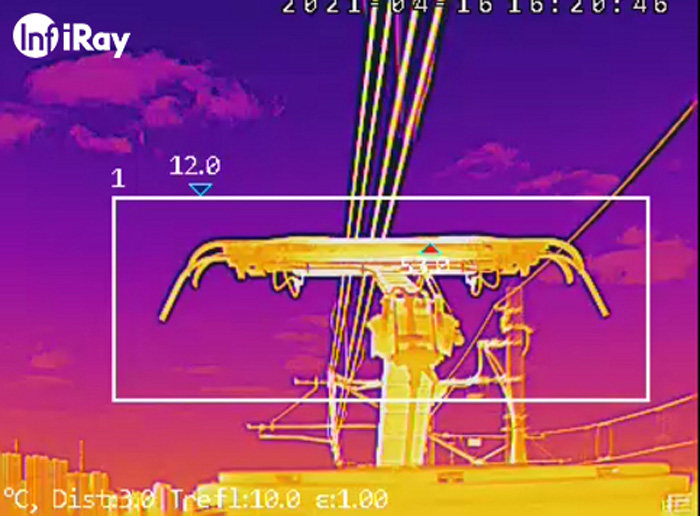

1. Overhead Line Catenary Monitoring

Due to mechanical tensions, over-heated connection faults are likely to occur for the catenary of the overhead line, causing connection fault due to over-heating. Consequently, the contact wire is extended and even loses tensions to become loose, blocking the electricity transmission over the contact wire. The temperature data with geographic locations, measured values, or operational status is continuously collected by the thermal camera at each measurement point. If exceptions occur, alarms are automatically generated, notifying staff to promptly handle the device fault, eliminating the danger before happening.

2. Pantograph Monitoring

The pantograph is installed on the roof of the high-speed train with no covers, and protection devices cannot be installed. In addition, the stress is complex for high-speed train operation, and therefore faults can easily occur. The thermal camera can observe the real-time heat distribution on the pantograph, and locate and diagnose pantograph exceptions when the train is moving at high speed. The thermal image is used for device fault diagnosis, and pre-warnings are provided for potential faults, ensuring the safety and smoothness of railway transportation.

II. Unique Advantages of Thermal Cameras in Pantograph-OCS System Monitoring

1. Thermal cameras feature 24-hour all-weather monitoring. They can normally operate in harsh weather and have ultra-strong protection in low-temperature environment and capabilities of high-temperature and high-humidity resistance

2. They implement non-contact online temperature measurement, and can automatically capture the hottest point on the screen or area without stopping the trains, to efficiently discover problems with no omissions

3. With professional PC software, multiple devices can be used for online real-time monitoring and data collection, to quickly and accurately identify the temperature and location of the fault point, ensuring the normal operation of the devices and smoothness of maintenance tasks