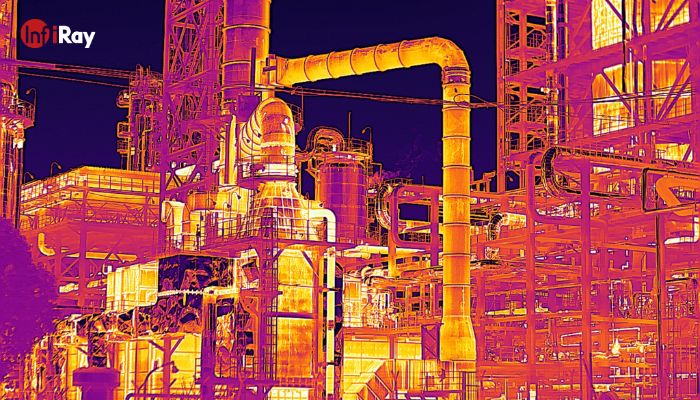

Top 4 Applications of Thermal Imaging in the Petrochemical Industry

The petrochemical industry stands at the forefront of technological advancements, constantly seeking innovative solutions to enhance efficiency and safety. Among these, thermal imaging has emerged as a game-changer, offering a myriad of applications that revolutionize operations in petrochemical plants.

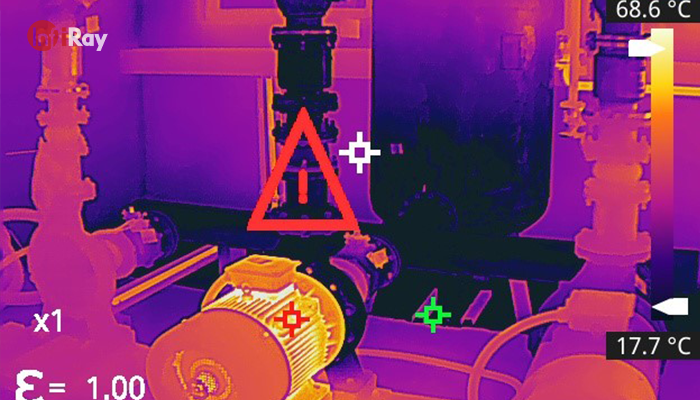

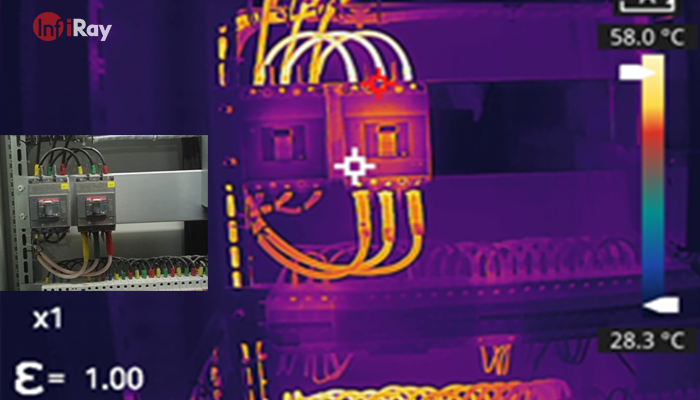

Application 1: Equipment Monitoring and Predictive Maintenance

In the complex web of machinery within petrochemical plants, ensuring the reliability of equipment is paramount. Thermal imaging proves invaluable in this regard, acting as the vigilant eyes that detect anomalies and potential failures before they escalate. By capturing infrared radiation, thermal cameras identify temperature variations that hint at malfunctioning components. This capability enables predictive maintenance, allowing for timely interventions and preventing costly downtime.

Real-life examples abound, such as a case where a thermal imager identified an overheating pump motor. Swift action was taken to rectify the issue, preventing a catastrophic failure that could have resulted in significant production losses.

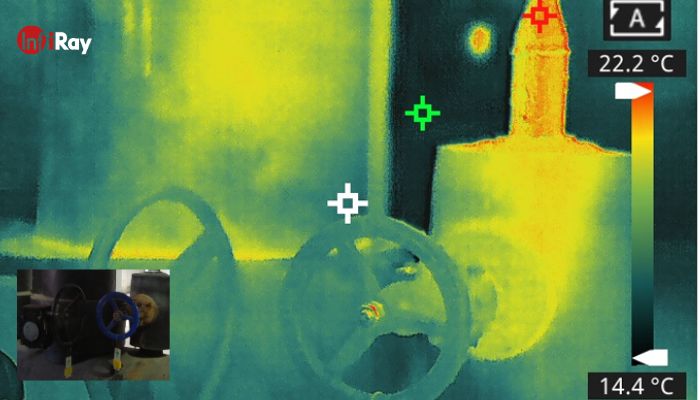

Application 2: Safety and Leak Detection

Safety concerns loom large in petrochemical plants, given the volatile nature of the materials processed. Thermal imaging takes center stage in mitigating risks by providing early detection of leaks and potential hazards. By visualizing temperature differentials, these cameras can pinpoint abnormalities, signaling the presence of gas leaks or other safety threats.

Notable instances include the identification of a concealed gas leak in a storage facility. Thanks to this cutting-edge tech, the leak was detected promptly, and emergency response measures were implemented, averting a potential disaster.

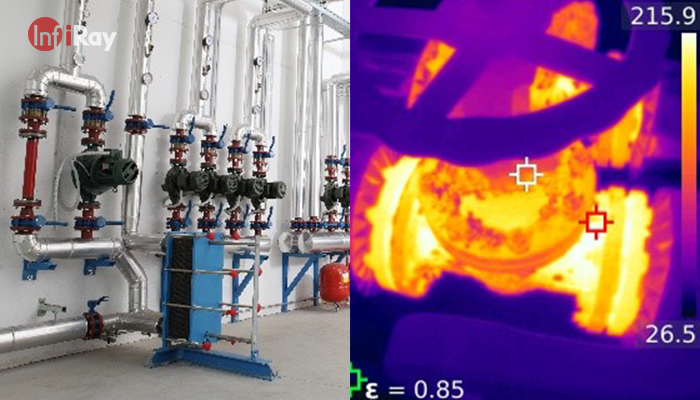

Application 3: Energy Efficiency and Process Optimization

Amidst global efforts towards sustainability, energy conservation in petrochemical processes is gaining prominence. Thermal imaging plays a pivotal role in this arena by identifying areas of heat loss and inefficiencies. By mapping temperature variations, operators can optimize processes, reduce energy consumption, and minimize environmental impact.

Consider a case where a thermal camera identified insulation gaps in a pipeline, leading to substantial energy savings after rectification. The technology not only enhances environmental stewardship but also contributes to cost-effectiveness in operations.

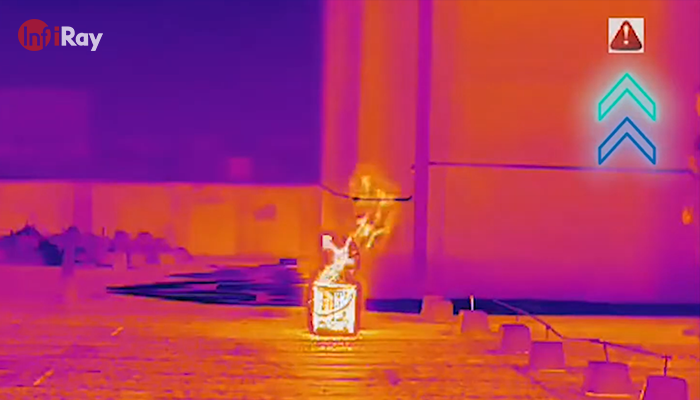

Application 4: Fire Prevention and Emergency Response

The specter of fire looms as a constant threat in petrochemical facilities. Thermal imaging emerges as a potent tool in early fire detection, offering a crucial advantage in emergency response planning. By swiftly identifying temperature spikes, these cameras enable operators to pinpoint potential ignition sources before a fire breaks out.

In one noteworthy case, thermal imaging detected a hot spot in an electrical panel, allowing for timely intervention and preventing a catastrophic fire. The technology proves indispensable in fortifying the layers of fire prevention and response strategies.

Advantages of Integrating Thermal Imaging:

The seamless integration of thermal cameras into petrochemical operations ushers in a host of unparalleled advantages, positioning it as an indispensable asset for the industry's future.

1. Enhanced Predictive Maintenance

By harnessing the power of thermal imaging, petrochemical plants gain a proactive edge in maintenance practices. The technology's ability to identify subtle temperature variations allows for the early detection of equipment issues, paving the way for timely interventions. This not only minimizes unplanned downtime but also maximizes the lifespan of critical assets, resulting in significant cost savings.

2. Augmented Safety Measures

Safety is paramount in the petrochemical realm, and thermal imaging amplifies the industry's safety measures. With their capacity to swiftly detect anomalies and potential hazards, such as gas leaks, thermal cameras become the frontline defense against accidents. Real-time visualization of temperature differentials ensures rapid response, mitigating risks and safeguarding both personnel and infrastructure.

3. Optimized Energy Consumption

As the world moves towards sustainable practices, energy efficiency becomes a key focus. Thermal imagers play a pivotal role in identifying areas of heat loss and inefficiencies in petrochemical processes. Armed with this information, operators can fine-tune processes, reduce energy consumption, and align operations with environmental stewardship goals. This not only enhances the industry's reputation but also contributes to long-term cost-effectiveness.

4. Early Fire Prevention

Petrochemical plants are inherently susceptible to fire risks. Thermal imaging, with its ability to detect temperature anomalies, becomes an invaluable tool in early fire prevention. By identifying potential ignition sources before a fire erupts, these cameras empower operators to implement preventive measures swiftly. This proactive approach significantly reduces the likelihood of catastrophic fires, safeguarding both assets and personnel.

5. Cost-efficiency and Operational Resilience

The integration of thermal imaging translates into tangible cost savings through predictive maintenance, energy optimization, and accident prevention. Beyond the immediate financial benefits, it fosters operational resilience by minimizing downtime and disruptions. This, in turn, enhances the overall efficiency and competitiveness of petrochemical operations in a dynamic market landscape.

As we delve into the top applications of thermal imaging in the petrochemical industry, it becomes apparent that this technology is a transformative force. From predictive maintenance to safety enhancement, energy conservation to fire prevention, thermal imaging stands as a beacon of innovation. Embracing these advancements is not just an option but a necessity for a resilient and forward-looking petrochemical industry.