Difficult to Detect Hollow Walls, Leakage, and Air Tightness? Building Detection Solution Using Thermal Cameras

Due to various factors in design, construction, and subsequent use, problems such as hollow external walls, liquid leakage in the wall, and poor airtightness frequently occur in buildings, adversely affecting living quality and causing potential safety issues. Thermal cameras are tools for building maintenance. They can detect the temperature difference on the building surface in a non-contact manner and quickly locate defect locations.

I. Main Applications of Thermal Cameras in Building Detection

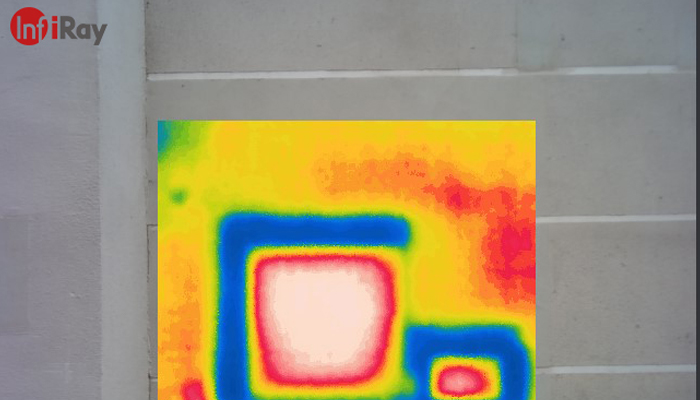

1. Hollow External Wall Detection

Hollowing is a phenomenon of insecure bonding between structural layers in the floors, walls, or suspended ceiling. Hollow external walls will cause temperature differences on the external walls. Thermal cameras can detect and display the temperature difference for engineers to quickly discover quality issues of the external wall and assist them to repair the wall.

2. Wall Leakage Detection

Damage to buildings will weaken the thermal insulation and cause problems such as rainwater leakage. Thermal cameras have excellent thermal sensitivity and can clearly display subtle temperature differences, to spot and locate the leakage point.

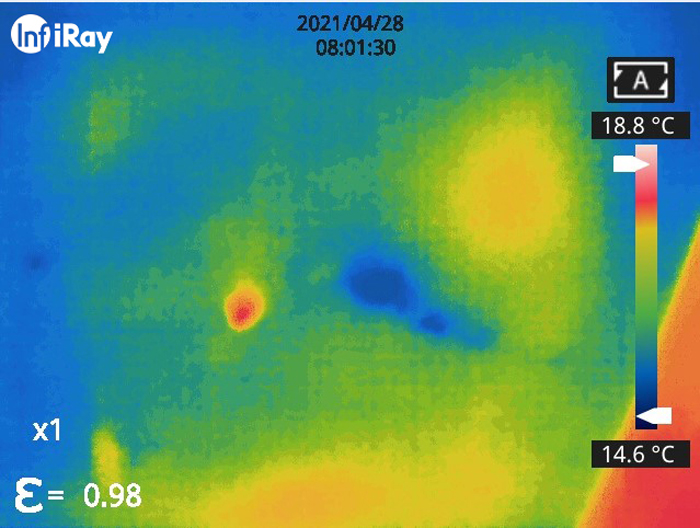

3. Air Tightness Detection of Buildings

Poor airtightness of buildings will cause problems such as cold air pumping into the room, heat leakage, and increased load of the heating system. Thermal cameras can be used to check key parts and provide an effective qualitative analysis basis for detection.

II. Unique Advantages of Thermal Cameras in Building Detection

1. Non-contact and non-destructive detection is supported. Without scaffolds, engineers can measure a large area, achieving high detection efficiency.

2. Dual-spectrum fusion and voice annotation functions (on some models) are supported, facilitating quick identification and fault location.

3. The temperature measurement area can be freely selected, and the data can be automatically collected. Secondary analysis of images is supported to avoid maintenance with no purpose.

4. The high and low-temperature alarms are supported to help engineers with building detection and management.