3 Roles of Thermal Imaging in Industrial Safety and Accident Prevention

In industries, safety always has a top priority, and one way to ensure that employees and equipment are safe is through thermal imaging. Thermal imaging is the use of infrared cameras to detect heat radiation and produce an image of the heat distribution on a surface. It is a non-contact and non-destructive method of detecting temperature changes, and it has a significant role in industrial safety and accident prevention.

Role 1: Detecting Overheating in Electrical Systems

Electrical safety is a significant concern in industrial settings. Overheating in electrical systems can result in equipment failure, fires, and even explosions. Regular inspections of electrical systems are essential to identify potential hazards before they cause an accident. However, traditional methods of inspection cannot detect these hazards all the time. This is where thermal imaging comes in.

Thermal imaging cameras can detect temperature changes and is especially useful for electrical systems. The cameras can detect hotspots, which are areas where the temperature is higher than the surrounding areas. These hotspots can be caused by a variety of factors, including overloaded circuits, damaged components, and worn-out equipment. By detecting hotspots early, engineers can take corrective actions to prevent equipment failure or fire. Check Out InfiRay® Thermal Imaging Monitoring Solution for High-Voltage Substations.

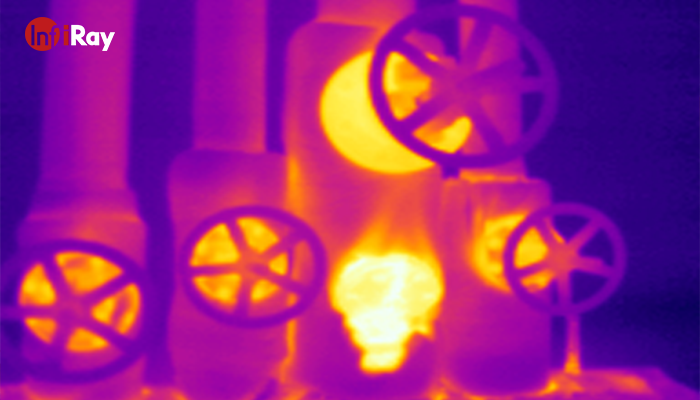

Did you find which parts were abnormal?

Role 2: Identifying Potential Mechanical Failures

Mechanical equipment is often used in industrial settings. Machinery can wear out and malfunction, leading to potential accidents. Identifying potential mechanical failures before they occur is crucial for industrial safety. This is where thermal imaging comes in.

Thermal imaging cameras can detect temperature changes in mechanical equipment. For example, excessive friction can cause a temperature increase in bearings, shafts, and gears. By detecting these temperature increases, engineers can take corrective actions to prevent equipment failure or accidents. This can include lubrication, alignment, or replacing damaged components.

The temperature in thermal imaging can alert engineers to the operating status of industrial equipment.

Thermal imaging can also detect pipe leaks, which can lead to environmental hazards and accidents. The cameras can detect temperature changes in the surrounding area caused by leaking fluids. This allows engineers to detect and repair leaks before they become a safety hazard. See How Thermal Cameras Discover Pipe Exceptions of Hot-Blast Stoves within 1 Second.

Role 3: Preventing Fires in Storage

Fires in storage areas can be catastrophic in industrial settings. Stored materials can ignite, leading to fires that can cause extensive damage to property and, more importantly, pose a significant risk to workers' safety. Identifying potential hazards in storage areas is crucial for industrial safety, and thermal imaging can play a crucial role in this regard. See How InfiRay Thermal Camera Safeguarding the Warehouse from Fire.

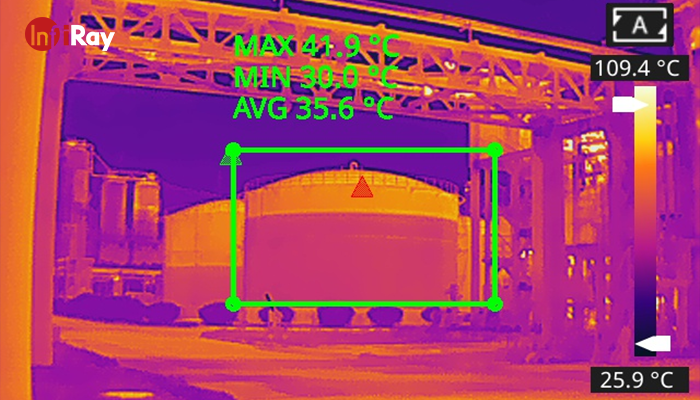

Thermal imaging cameras can detect temperature variations in storage areas. This is especially useful in detecting hotspots that can indicate potential fire hazards. For instance, overheating electrical equipment, faulty storage tanks, or chemical reactions can generate heat and cause hotspots in storage areas. By detecting these hotspots early, engineers can take corrective actions to prevent fires from occurring.

InfiRay online thermal imaging monitors storage 24/7 and provides timely alerts

Thermal imaging can also detect the temperature of stored materials. Some materials are prone to spontaneous combustion or can react violently with other materials when exposed to heat or moisture. By monitoring temperature changes in stored materials, engineers can take the necessary precautions to prevent accidents and fires.

InfiRay thermal imaging system is alerting to the point of fire

Thermal imaging is an invaluable tool for industrial safety and accident prevention, with a range of applications across multiple industries. It can help detect potential hazards that may not be visible to the naked eye, allowing engineers to take corrective actions before an accident occurs. It can detect hotspots in electrical systems, temperature changes in mechanical equipment, leaks in pipes, moisture in building materials, and potential fire hazards in storage areas. By incorporating thermal imaging technology into their safety plans, industrial organizations can improve safety, reduce the risk of accidents, and protect the health and well-being of their workers.