In-Depth Analysis: Application of Thermal Cameras in Rotary Kiln Fault Diagnosis at Iron and Steel Plants

At an iron and steel plant, the rotary kiln is an important device for calcining pallets in the ironmaking process. The rotary kiln body is the part that is heated. The inner lining of the rotary kiln is refractory, and a steel plate is on the surface. During normal operation, the internal temperature is over 1200°C, and the burning zone temperature is 1300 to 1400°C. Non-stop temperature measurement and temperature trend analysis of the inner shell and outer shell of the rotary kiln by using thermal cameras are particularly important.

I. Pain Points in the Industry

The inner wall close to the rotary kiln head has the highest temperature in the rotary kiln. With the increasing time of rotary kiln operations, the inner lining will become thinner and even fall off due to the constant high temperature and friction of clinkers. Consequently, the pipe wall temperature changes drastically, and the temperature in the rotary kiln becomes unevenly distributed, hampering stable and reliable operations of rotary kilns. An overly high temperature will cause over-calcination and a low temperature will cause under-calcination. Therefore, a too high or low temperature will not produce ideal calcination results. Traditional manual inspection can hardly discover exceptional areas, and cannot enable effective safety control for rotary kilns.

II. Main Applications of Thermal Cameras in Rotary Kilns

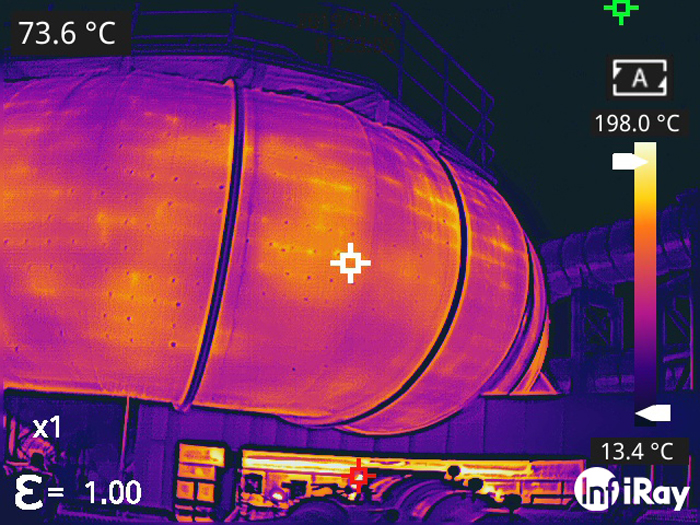

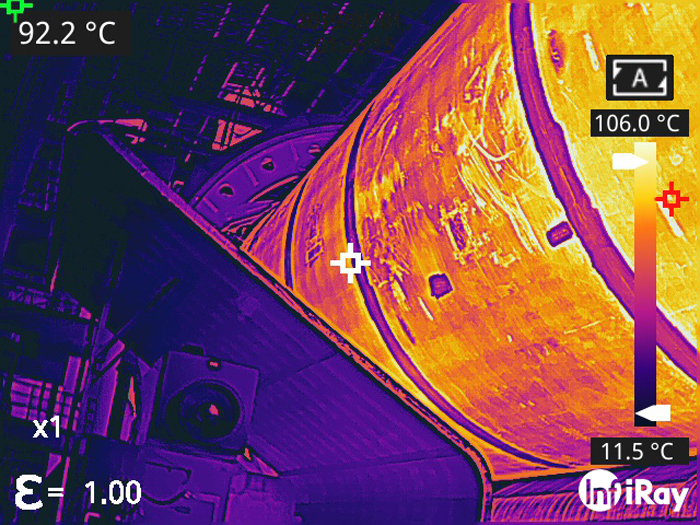

Temperature Monitoring of the Rotary Kiln Outer Wall

The rotary kiln is large and keeps rotating, causing difficulties in the manual inspection. Besides, single-point temperature measurement will cause detection omission, and faults cannot be promptly eliminated. Thermal cameras enable all-weather temperature monitoring, temperature trend analysis, and alarm prompt for the rotary kiln outer wall, to replace manual inspection. The thermal cameras effectively transmit images and temperature data to the control room in real-time, to prevent, handle, and trigger alarms for problems.

The rotary kiln head sprays fuel into the kiln. The exhaust gas generated through combustion goes to the material and then is let out from the rotary kiln discharge head. The temperature gradually decreases from the rotary kiln head to the rotary kiln discharge head. The temperature at the quenching position of the rotary kiln head can reach 1400°C, but the temperature at the rotary kiln discharge head is only 500 to 800°C. Thermal cameras can monitor the operation status and temperature fields of the combustion in the rotary kiln in real-time, for real-time visual display of temperature and history temperature queries.

III. Unique Advantages of Thermal Cameras in Rotary Kiln Detection

1. Professional temperature measurement tools help freely select monitored areas and automatically obtain the highest temperature point for regular inspection. Thermal image comparison helps discover the damage in the kiln lining, and notify staff or link automation devices for control.

2. The settings of temperature threshold, duration, and sampling interval are available to achieve data collection. Thermal cameras are used to measure the temperature field of the outer wall. Then, analysis is conducted for the linear relationship between the outer wall temperature and corrosion in the inner lining refractory, and the obtained relationship serves as the reference to making maintenance plans.

3. Thermal cameras feature flexible and convenient operations. Preliminary constructions such as fixed platform installation and cable layout are no longer needed, and the device maintenance cost is relatively low.

4. The secondary development pack SDK is provided for users' secondary development.