Applications of Thermal Cameras in the Manufacture of Fiber Lasers

Fiber lasers feature excellent beam quality, high energy density, high electro-optical conversion efficiency, good thermal diffusivity, compact structure, flexible transmission, and eliminating the need for maintenance. Such lasers signify the development direction of laser technology and have become the major choice in applications. The overall electrical-optical efficiency of fiber lasers is 30% - 35%, and most of the energy is dissipated in the form of thermal energy. Hence, temperature control during the operation of such lasers determines their quality and service life. The conventional contact temperature measurement method damages the structure of lasers, while the single-point non-contact measurement solution cannot accurately capture fiber temperature. Using a thermal camera to detect the temperature of a whole optical fiber, especially that of its fusion splices, can ensure the R&D and quality of optical fiber products.

I. Main Applications of Thermal Cameras in Safety Monitoring of Optical Fibers

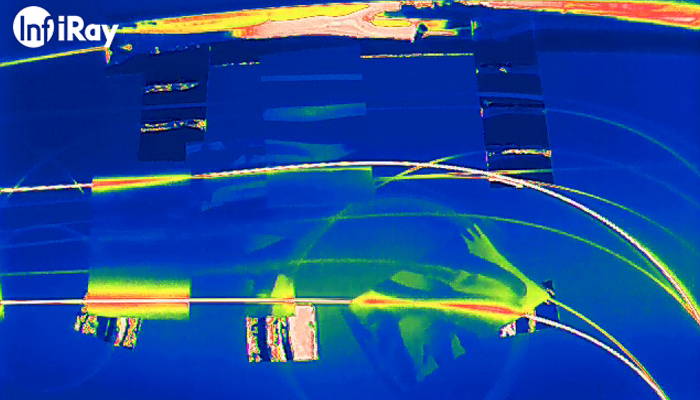

Fusion splice quality monitoring

During the manufacture of a high-power fiber laser, there are certain optical discontinuities and defects at the fusion splices, and serious defects will cause abnormal heating of the fusion splices, resulting in damages to the laser or the heating splice. Therefore, temperature monitoring of fiber fusion splices is an important part of fiber laser manufacturing. Thermal cameras can realize temperature monitoring of fusion splices, thus helping determine whether the quality of the fusion splices being monitored is acceptable and improving product quality as a whole.

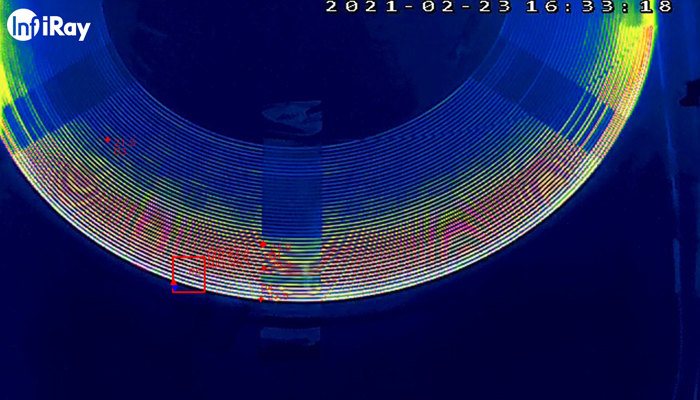

LD pump source

The laser power output by a single LD chip is limited. A pump packages several LD chips together to increase the output power. Such a pump usually generates a large amount of heat, thus temperature directly affects the laser wavelength output by the chips. Thereby, incoming quality inspection should be carried out on each pump using a thermal camera, so as to return unqualified pumps and ensure the overall laser quality.

Verification of laser reflection protection

Fiber lasers are vulnerable to back reflections from metal workpieces. Therefore, high-quality fiber lasers require a reflection protection mechanism and laser reflections with a certain power should be simulated on the lasers to ensure quality. Inspection using a thermal camera can verify that the reflection protection mechanism of lasers is reliable.

Laser combiner

A laser combiner can synthesize N-line pump lasers into a 1-line laser to ensure the high power output of a laser device. Pre-delivery inspection using a thermal camera can effectively reduce the probability of return.

II. Unique Advantages of Thermal Cameras in Fiber Laser Inspection

Thermal cameras serve to achieve remote and non-contact temperature measurement and eliminate the need for disassembly

With professional measurement tools, monitor the areas selected and automatically obtain the highest temperature point

The setting of temperature threshold, duration, and sampling interval is available to achieve data collection and curve generation

Various forms of alarms and linkages are available to provide notes to workers or automation equipment for management and control

Secondary development and technical services facilitate the creation of customers' autonomous edge