3 Top Benefits of Thermal Imaging for Condition Monitoring

In today's industrial landscape, ensuring the smooth operation of equipment is crucial for maintaining productivity and safety standards. That's where thermal imaging technology comes into play, offering a range of benefits for condition monitoring that can significantly enhance maintenance practices. Let's explore the three top benefits of incorporating thermal imaging into your condition-monitoring strategy.

Benefit 1: Early Detection of Equipment Failure

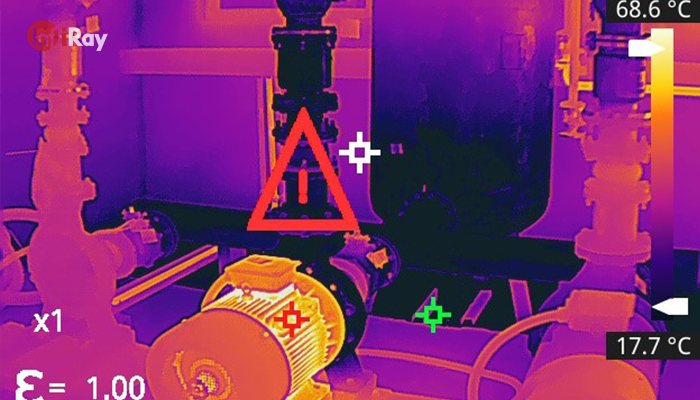

One of the most significant advantages of thermal imaging is its ability to detect potential equipment failures at an early stage. By capturing thermal images of machinery and infrastructure, thermal cameras can identify anomalies such as overheating components or electrical hotspots that may indicate impending malfunctions.

For instance, a slight increase in temperature in a motor or a bearing may go unnoticed through visual inspection alone. However, thermal cameras can highlight these temperature variations, allowing maintenance teams to address issues before they escalate into costly breakdowns. This early detection not only minimizes downtime but also reduces repair costs, ultimately optimizing operational efficiency.

Benefit 2: Improved Safety

Safety is paramount in any industrial setting, and thermal imaging can play a vital role in enhancing workplace safety. By identifying potential hazards such as overheating electrical components or leaks in pipelines, thermal imaging enables proactive measures to be taken to mitigate risks.

Consider a scenario where an electrical panel is gradually overheating due to a loose connection. Without thermal imaging, this issue might remain undetected until it leads to a fire or equipment failure. However, with regular thermal inspections, maintenance personnel can identify and rectify the problem before it poses a safety threat. This proactive approach not only protects employees and assets but also ensures compliance with safety regulations.

Benefit 3: Enhanced Efficiency and Accuracy

In addition to early detection and improved safety, thermal imaging offers significant gains in efficiency and accuracy compared to traditional monitoring methods. Traditional methods often involve manual inspections, which can be time-consuming and prone to human error.

Thermal imaging, on the other hand, provides non-contact, non-destructive testing that allows for quick and comprehensive assessments of equipment conditions. With the ability to capture detailed thermal images of large areas in a matter of seconds, thermal cameras streamline the inspection process, saving time and resources. Expended Reading: Can a Thermal Camera Detect Industrial Air Leaks

Moreover, those cameras offer unparalleled accuracy in detecting subtle temperature variations that may indicate underlying issues. This level of precision enables maintenance teams to make informed decisions based on reliable data, ensuring optimal performance and longevity of equipment.

Thermal imaging technology offers three key benefits for condition monitoring: early detection of equipment failure, improved safety, and enhanced efficiency and accuracy. By incorporating thermal imaging into your maintenance strategy, you can proactively identify issues, mitigate risks, and optimize operational performance.