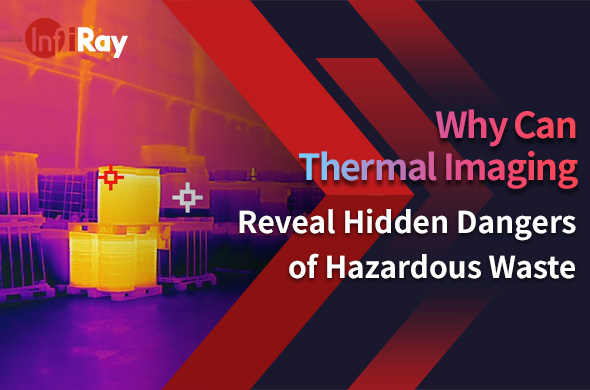

Why Can Thermal Imaging Reveal the Hidden Dangers of Hazardous Waste

Hazardous waste, a byproduct of industrial and commercial processes, poses a severe threat to both the environment and human health. The hidden perils within hazardous waste storage and disposal can lead to catastrophic incidents, ranging from chemical leaks to fires, causing irreparable damage. In the realm of modern technology, there exists a powerful tool that can help us reveal the unseen threats lurking beneath the surface – thermal imaging.

Uncovering Hidden Incidents

Traditional monitoring methods can only identify surface hazards, while thermal imaging can conduct continuous monitoring of hazardous waste, displaying real-time temperature information for the monitored objects. They support multiple cameras working together to generate alarms in the event of a sudden temperature change in the target, effectively suppressing any potential fire before it ignites.

Secondary Combustion Chamber Temperature Monitoring

The secondary combustion chamber is an exhaust gas secondary combustion system installed at the rear section of the rotary kiln. It effectively eliminates unburned organic components and other harmful gases in the exhaust gas from the rotary kiln, ensuring pollution-free emission of gases in the rear section. Real-time temperature data collection is performed using a thermal camera, with a set temperature upload interval. Data processing on the software end generates temperature data curves. Based on these curves, temperature change trends are predicted, enabling effective monitoring and assessment of the incineration process inside the secondary combustion chamber to ensure its safe operation.

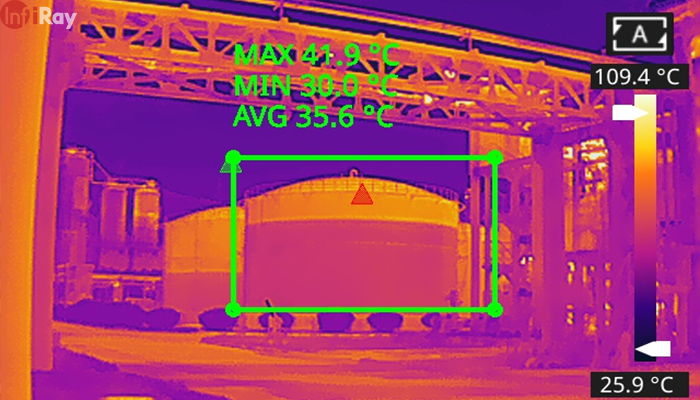

Waste Pit Temperature Monitoring

Waste pits are primarily used for the temporary storage, mixing, and preparation of waste for incineration. These pits store various types of hazardous waste, often with complex characteristics, including flammable and reactive materials that can undergo intense combustion reactions within the pit, leading to spontaneous combustion. Traditional visible light fire alarm algorithms only trigger alarms after the pit has caught fire, posing significant risks to life and property once the fire spreads. Using thermal imaging for comprehensive temperature monitoring of waste pits allows for timely detection of areas with abnormally high temperatures. This enables prioritized actions such as cooling or water spraying to prevent temperature escalation and the outbreak of fires.

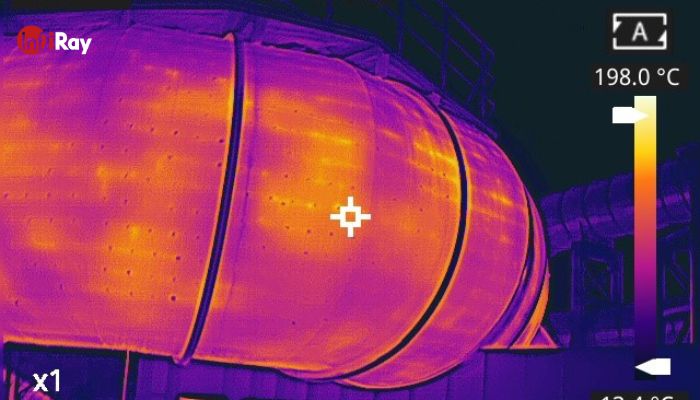

Rotary Kiln Temperature Monitoring

Inside the rotary kiln, there is a layer of refractory material, and the outer layer is a steel plate enclosure. During operation, the internal refractory material of the kiln is eroded and even peeled off, leading to the steel plates being directly exposed to high-temperature environments, which can soften and even melt, posing a serious threat to production safety. Using thermal imaging enables continuous monitoring of the rotary kiln, displaying real-time temperature information of the kiln's outer wall. This allows for a prior understanding of the extent of erosion of the internal refractory material, supports multiple units for coordinated alarms, and the setup of multiple temperature measurement zones, aiding in the timely implementation of preventive measures to prevent kiln penetration accidents.

Solutions and Prevention

Now that we understand the range of hidden incidents that thermal imaging can uncover, let's explore the solutions we offered and how it contributes to prevention.

1. Early Warning

Traditional smoke sensors or visible light monitoring systems can only detect fires at the smoldering or open flame stage, while thermal imaging can identify temperature anomalies in the initial stages of fire ignition, enabling early warning.

Continuous monitoring with thermal imaging allows for non-contact temperature measurement, temperature visualization, all-around coverage, ensuring safety and providing intuitive data.

3. Fire Integration

InfiRay's thermal imaging solutions not only excel in uncovering hidden dangers in hazardous waste management but also offer seamless integration with fire suppression systems. This innovative feature represents a significant advancement in enhancing safety measures, as it enables the automatic elimination of hazards in the event of a fire emergency.

4. Alarm Integration

By linking pop-up alerts and audible-visual alarms to its thermal imaging solutions, InfiRay ensures that its technology is not only capable of detecting anomalies but also of providing a rapid and effective response.

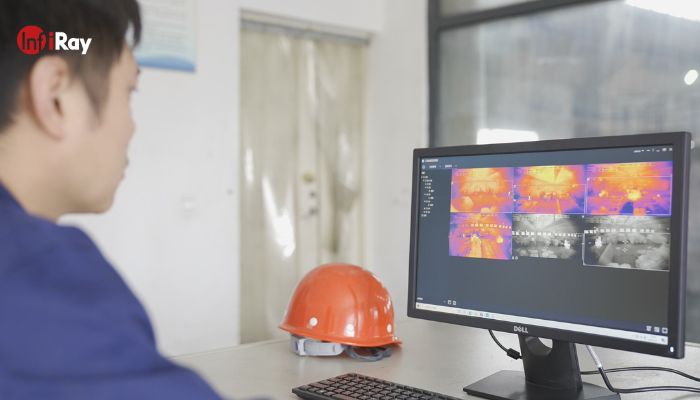

5. System Software

All online temperature measurement devices within the factory can be connected to the local network, and industrial temperature monitoring system software can manage them collectively, offering an economical and practical solution.

Thermal imaging is a powerful tool for uncovering hidden incidents, offering practical solutions, and preventing disasters. This cutting-edge technology goes beyond the visible spectrum of light to expose hidden incidents that can have a profound impact on our lives. As technology continues to advance, thermal imaging becomes more accessible and affordable, making it a valuable addition to your safety and maintenance toolkit. So, don't wait until hidden incidents become major problems – start utilizing thermal imaging today.