3 Reasons Why Condition Monitoring cannot be done Without Thermal Imaging

In the current industry environment, It is crucial to maintain smooth facility operations to ensure high productivity and security levels. This is a critical stage in the development of thermographic techniques. By implementing status monitoring, maintenance processes can experience significant benefits. Let's look at the three main advantages of using thermal images in your status surveillance strategy.

Benefit 1: Thermal Imaging Helps Equipment Failure Early Detection

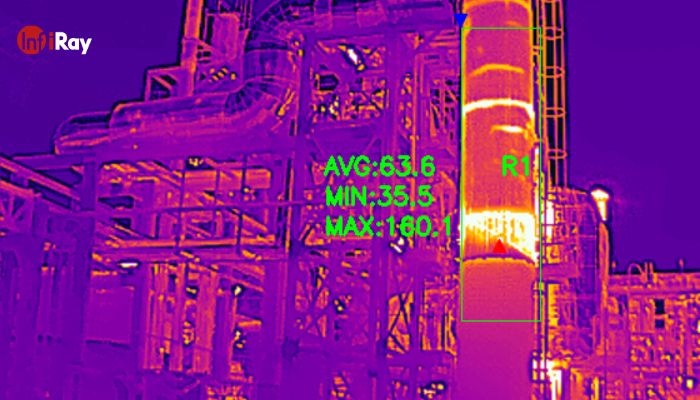

Thermal imaging is a useful technology that can quickly identify possible malfunctions. By creating heat maps of machines and facilities, the camera can detect abnormal conditions such as overheating parts or electric hot spots that may indicate an impending failure. This capability makes thermal imaging an effective tool for preventive maintenance, as it can address potential problems before they become serious issues.

A small rise in engine or shaft temperature can easily be missed without proper monitoring. However, the thermal camera can make those changes more noticeable so that the repair group can fix the problem before it becomes a more expensive problem. Not only does this early discovery minimize the time spent on the system, but it also lowers the cost of maintenance and eventually improves the operating efficiency.

Benefit 2: Thermal Imaging Can Improve Safety

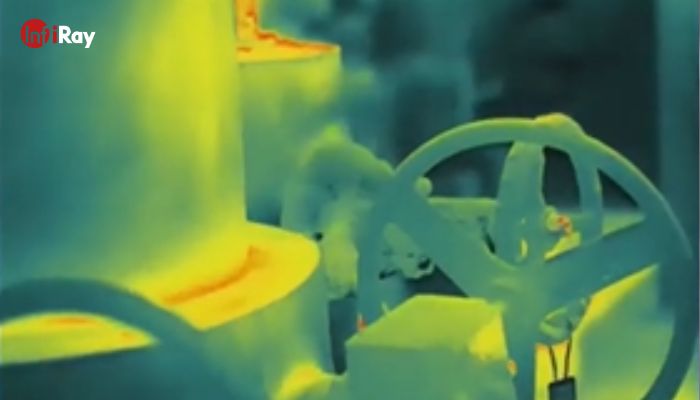

Safety is of the utmost importance in any industry environment, and the use of thermography to improve the working environment is crucial. Thermal imaging cameras can detect potential hazards such as overheated electrical components or leaking pipes, reducing risks promptly.

Think of a situation in which an electric board starts to heat up as a result of a loose connector. In the absence of thermal imaging, the problem may go unnoticed until it results in a fire or a malfunction of the device. With periodic heat checks, however, maintenance staff will be able to detect and correct these issues before they become unsafe. This initiative ensures the protection of workers, property, and compliance with safety rules.

Benefit 3: Thermal Imaging Can Enhance Efficiency and Precision

Apart from being detected at an early stage and being more secure, thermal imaging provides a great improvement in performance and precision over conventional surveillance techniques. Conventional approaches usually require manual testing, which is time-consuming and easy for people to make mistakes.

Thermography offers noncontact, nondestructive testing, which enables a rapid and complete evaluation of the state of the device. Thanks to its capability of taking detailed heat pictures over a wide range in just a few seconds, the thermal camera can make it easier to inspect and save time and resources.

In addition, the cameras can detect even the smallest temperature changes, which could be an indication of underlying issues. This degree of accuracy allows the maintenance group to make an informed decision based on solid data, thereby guaranteeing the optimum performance and lifetime of the device.

Thermal imaging provides three major benefits to condition monitoring systems: timely detection of equipment failures, increased safety, and enhanced system effectiveness and accuracy. By incorporating thermal imaging into your service policy, you will be able to proactively identify problems, reduce risk, and optimize operations.