What Are Infrared Camera Cores And How to Choose

In today's world, where technology plays a vital role in various industries, the use of infrared camera cores has become increasingly prevalent. These sophisticated devices offer a wide range of applications, from surveillance and security to medical imaging and industrial inspection. But what exactly are infrared camera cores, and how do you choose the right one for your needs? In this comprehensive guide, we'll delve into the intricacies of infrared camera cores, their functionality, and provide valuable insights on selecting the best one for your requirements.

Understanding Infrared Camera Cores

What Are Infrared Camera Cores?

Infrared camera cores, also known as thermal imaging cores, are the heart of thermal imaging devices. They are responsible for capturing and processing thermal radiation emitted by objects in the environment. Unlike traditional cameras that rely on visible light, infrared camera cores detect heat signatures emitted by objects, enabling users to visualize temperature differences and identify potential anomalies.

How Infrared Camera Cores Work

These cores operate on the principle of thermal imaging, where specialized sensors detect infrared radiation emitted by objects. The captured radiation is then converted into electrical signals, which are processed to create thermal images. Advanced algorithms and image processing techniques enhance the clarity and accuracy of the images, providing valuable insights into temperature variations and heat patterns.

Types of Infrared Camera Cores

Infrared camera cores are broadly classified into two categories: uncooled and cooled cores.

Uncooled Infrared Camera Cores: These cores feature sensors that do not require cryogenic cooling. They are compact, lightweight, and suitable for various applications, including consumer electronics and firefighting.

Cooled Infrared Camera Cores: Cooled infrared thermal cores utilize cryogenic cooling to enhance sensitivity and image quality. They are commonly used in demanding applications such as surveillance and scientific research.

Advantages of Using Infrared Camera Cores

1. Enhanced Visibility: Infrared camera cores can detect objects and anomalies in complete darkness or adverse weather conditions where visible light cameras fail.

2. Non-Destructive Testing: These cores enable non-destructive testing by detecting temperature variations without physical contact, making them ideal for inspecting delicate components.

3. Increased Efficiency: By identifying temperature anomalies and potential defects early on, infrared camera cores help streamline maintenance processes and prevent costly downtime.

Factors to Consider When Choosing Infrared Camera Cores

Resolution and Image Quality

High resolution ensures clarity and detail in thermal images, allowing for precise analysis and interpretation.

Sensitivity and Detection Range

Opt for cores with high sensitivity to detect subtle temperature differences accurately, especially in challenging environments.

Frame Rate and Refresh Rate

A higher frame rate enables real-time monitoring and faster data acquisition, crucial for dynamic applications such as aerial surveillance and vehicle navigation.

Size, Weight, and Power Consumption

Consider the physical dimensions and power requirements of the core, ensuring compatibility with your intended application and platform.

Compatibility and Integration

Choose cores that seamlessly integrate with your existing systems and software, facilitating easy installation and operation.

Budget Considerations

Balance performance requirements with budget constraints, opting for cores that offer the best value for your investment.

Applications of Infrared Camera Cores

Surveillance and Security

Infrared camera cores play a crucial role in surveillance and security applications, monitoring sensitive areas and detecting intruders even in low-light conditions.

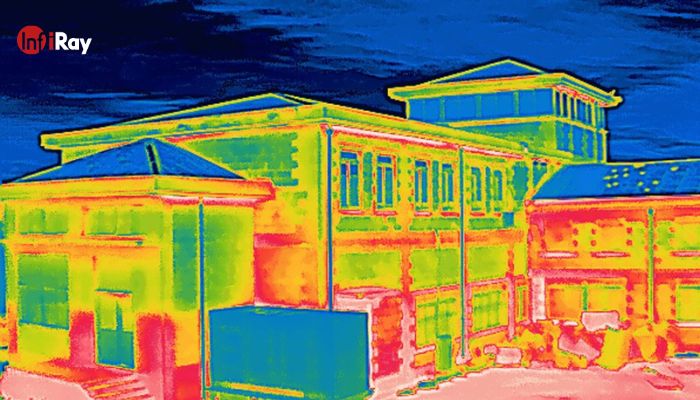

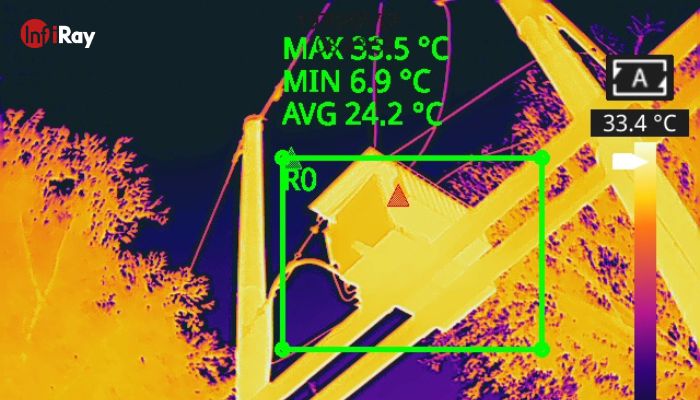

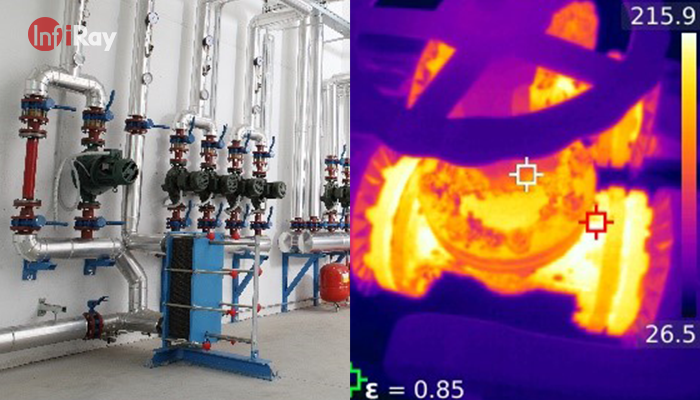

Thermography and Temperature Measurement

These cores are extensively used in thermography and temperature measurement, enabling precise monitoring of industrial processes, building diagnostics, and medical imaging.

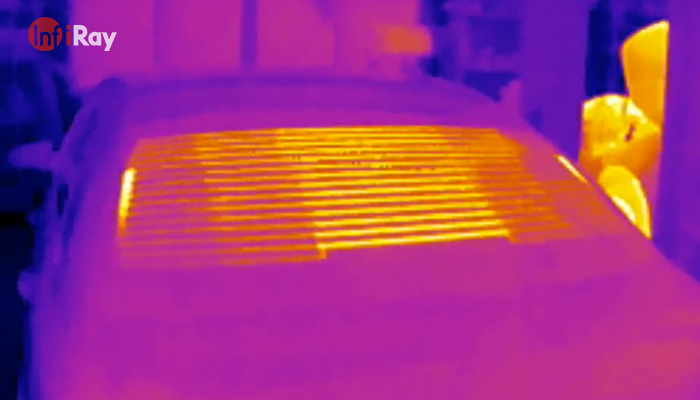

Automotive and Transportation

In the automotive industry, infrared camera cores are employed for driver assistance systems, night vision, and vehicle detection, enhancing safety and navigation capabilities.

Medical Imaging

Infrared camera cores are utilized in medical imaging applications such as thermography, diagnostics, and monitoring patient conditions, aiding in early disease detection and treatment.

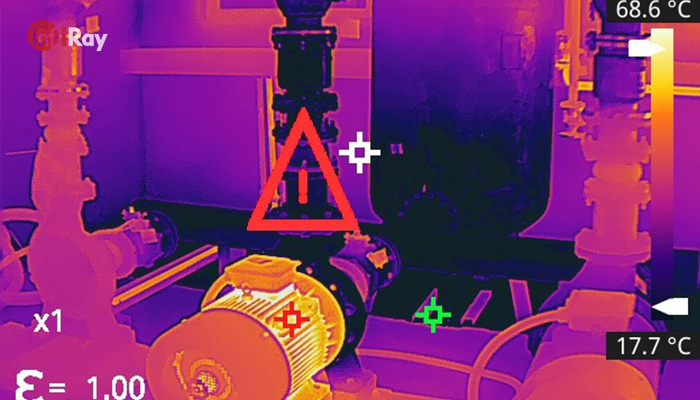

Industrial Inspection and Maintenance

Infrared camera cores facilitate proactive maintenance by identifying equipment failures and inefficiencies, minimizing downtime, and optimizing operational efficiency.

How to Choose the Right Infrared Camera Core

Assessing Your Specific Needs and Requirements

Understand your application requirements and performance expectations to narrow down the options and prioritize essential features.

Researching Available Options and Brands

Explore different infrared camera cores available in the market, considering factors such as technical specifications, reliability, and customer reviews.

Consulting with Experts and Peers

Seek advice from industry experts and peers who have experience with infrared camera cores, gaining valuable insights and recommendations.

Testing and Evaluating Different Camera Cores

Whenever possible, test the performance of different camera cores in real-world scenarios to assess their suitability and effectiveness.

Considering Long-Term Support and Maintenance

Choose a reputable manufacturer that offers comprehensive support and maintenance services, for example, InfiRay infrared thermal core, ensuring the longevity and reliability of your investment.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar