How Thermal Imaging Cameras Are Revolutionizing Industrial Inspections

How Can Thermal Imaging Cameras Revolutionize Industrial Inspections

In today's fast-paced industrial world, inspections are a critical part of ensuring that equipment, machinery, and other critical assets are running efficiently and safely. However, traditional inspection methods can be time-consuming, inaccurate, and even dangerous. This is where thermal imaging cameras come in. These cameras have revolutionized the way how industries conduct inspections, allowing for quicker, more accurate, and safer assessments of equipment, machinery, and other critical assets. In this article, we will take a closer look at how thermal imaging cameras update the industrial inspection process and how they can help prevent costly downtime and improve overall efficiency.

What is Thermal Imaging?

Thermal imaging is a non-contact, non-destructive method of capturing and analyzing the infrared radiation emitted by objects. This technology has many advantages when it comes to industrial inspections. For example, thermal imaging cameras can detect temperature differences that are not visible to the human eye, making it easier to identify potential problems with machinery and equipment before they become major issues. These cameras can also capture images from a distance, reducing the need for workers to climb ladders or work in hazardous conditions.

How Does Thermal Imaging Cameras Update Industrial Inspections?

The use of thermal imaging cameras in industrial inspections has been a game-changer. These cameras provide real-time information about the condition of machinery and equipment, allowing for quicker, more accurate, and safer assessments of critical assets. This information can be used to identify potential problems before they cause downtime or other issues. For example, a thermal imaging camera can detect overheating in an electrical system, which could be an early warning sign of a potential electrical failure. By identifying this issue early on, maintenance crews can take action to prevent downtime and reduce the risk of equipment failure. InfiRay thermal cameras have a wide range of applications in various industries.

Some thermal imaging cameras can provide real-time information, which is a superior advantage. The information can be used to optimize maintenance schedules and reduce the need for costly repairs. For example, by identifying potential problems early on, companies can schedule maintenance at the most convenient time, reducing downtime and minimizing the impact on production. This can lead to significant cost savings over time, making thermal imaging cameras a smart investment for many industrial businesses.

Handheld thermal imaging cameras for industrial temperature measurement

Thermal Imaging Cameras and Safety

Another advantage of thermal imaging cameras is that they can help prevent accidents and injuries in the workplace. By identifying potential hazards before they become major issues, thermal imaging cameras can help workers avoid dangerous situations. For example, a thermal imaging camera can detect hot spots in machinery that could cause burns or other injuries. By identifying these hot spots early on, workers can take steps to avoid them and prevent accidents from occurring.

In addition to improving safety and efficiency, thermal imaging cameras can also save companies money. By detecting potential problems early on, companies can take action to prevent downtime and reduce the need for costly repairs. This can lead to significant cost savings over time, making thermal imaging cameras a smart investment for many industrial businesses.

Remote inspections prevent accidents from occurring

Thermal Imaging Cameras in the Energy Sector

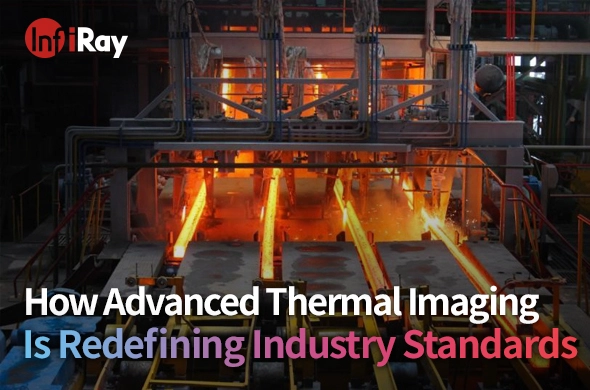

Thermal imaging cameras are commonly used in the energy sector to inspect pipelines, turbines, and other critical assets. These cameras can detect temperature changes and hot spots that may indicate problems with equipment or leaks in pipelines. By identifying these issues early on, companies can take action to prevent costly downtime and ensure the safe and efficient operation of their equipment.

InfiRay industrial thermal imaging cameras are able to detect energy leaks in time

Thermal Imaging Cameras in Manufacturing

Thermal imaging cameras are also widely used in the manufacturing industry to inspect machinery and equipment. These cameras can detect potential problems with bearings, motors, and other critical components, allowing maintenance crews to take action before equipment failure occurs. By identifying potential problems early on, companies can reduce downtime and improve the overall efficiency of their operations.

Thermal Imaging Cameras in the Building and Construction Industry

The building and construction industry is another area where thermal imaging cameras are being used to great effect. These cameras can be used to identify potential problems with HVAC systems, electrical systems, and building insulation. By identifying potential issues early on, building and construction companies can take action to ensure the safety and energy efficiency of their buildings.

In addition to detecting potential problems, thermal imaging cameras can also be used to verify the quality of construction materials. For example, these cameras can detect voids in concrete, which can compromise the strength and durability of a building. By identifying these issues early on, building and construction companies can take action to ensure the structural integrity of their buildings. You can learn more about Thermographic Camera in HVAC of Buildings.

Thermal cameras used in building and construction

In conclusion, thermal imaging cameras have revolutionized the way industries conduct inspections, allowing for quicker, more accurate, and safer assessments of critical assets. These cameras can detect temperature differences that are not visible to the human eye, providing real-time information about the condition of machinery and equipment. This information can be used to identify potential problems before they become major issues, optimizing maintenance schedules and reducing the need for costly repairs.

Thermal imaging cameras are widely used in the energy, manufacturing, building, and construction industries to inspect pipelines, turbines, machinery, and other critical assets. These cameras can help prevent accidents and injuries in the workplace and save companies money by reducing downtime and improving efficiency.

If you are looking to improve the efficiency and safety of your industrial operations, thermal imaging cameras are definitely worth considering. By providing real-time information about the condition of critical assets, these cameras can help you identify potential problems before they become major issues, saving you time and money in the long run.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar