Can Thermal Cameras Be Used in Harsh Environments?

Thermal cameras have become an increasingly popular tool across many industries, including industrial manufacturing, energy production, security, and surveillance. These cameras are designed to capture images based on the heat signatures emitted by objects, making them highly effective in a variety of applications. However, in harsh environments, thermal cameras may face challenges that can affect their accuracy and performance. In this article, we will explore the use of thermal cameras in harsh environments, the challenges they may face, and the strategies that can be used to overcome these challenges. Want to learn more about InfiRay thermal imaging technology applications and solutions in various industries? Click to view.

InfiRay thermal imaging camera for industrial pipeline inspection

Extreme Temperatures

One of the most significant challenges that thermal cameras face in harsh environments is extreme temperatures. High temperatures can cause thermal cameras to overheat, leading to reduced accuracy and performance. In contrast, low temperatures can cause the camera's display to freeze or become distorted, making it difficult to obtain accurate readings.

To address these challenges, manufacturers have developed thermal imaging cameras with ruggedized housings and advanced cooling systems that can withstand harsh temperatures. These cameras are often used in applications where traditional cameras may not be effective, such as in the automotive industry or power plants. For example, they can be used to detect overheating in car engines or identify areas of heat loss in power plant equipment.

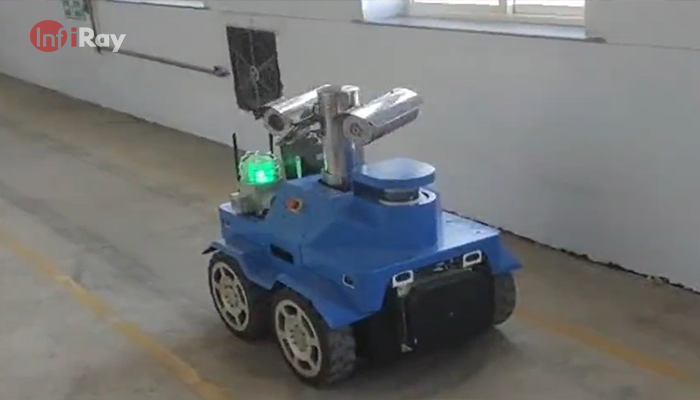

InfiRay Thermal Imaging Cameras and Robots Combine to Provide Safety for Hazardous Environment Inspections

In addition to ruggedized housings and cooling systems, thermal cameras may also feature automatic gain control, which allows the camera to adjust the image's brightness based on the temperature range. This feature helps to ensure that the camera can capture accurate images in a wide range of temperatures.

High Humidity

Another challenge that thermal cameras may face in harsh environments is high humidity. Humidity can cause condensation to form on the camera's lenses, which can obscure the camera's view and lead to inaccurate readings. In some cases, high humidity can also affect the camera's electronics, leading to reduced accuracy and performance.

To address these challenges, anti-fogging coatings or built-in heaters can be used to prevent condensation from forming on the lenses of thermal cameras. Anti-fogging coatings are typically applied to the lens surface and work by reducing the surface tension of water droplets, preventing them from forming on the lens. Built-in heaters work by warming the lens surface, preventing condensation from forming and allowing the camera to capture accurate images. Find more thermal imaging cameras for ocean perimeter applications here.

InfiRay thermal imaging cameras work in high humidity and foggy environments such as the ocean

Chemical Exposure

Chemical exposure is another challenge that thermal cameras may face in harsh environments. Exposure to chemicals can cause damage to the camera's lenses, sensors, and other components, leading to reduced accuracy and performance. In some cases, exposure to chemicals can also cause the camera's housing to deteriorate, reducing its ability to withstand harsh environments.

To protect thermal cameras from chemical exposure, manufacturers have developed cameras with protective coatings and housings that can withstand exposure to harsh chemicals. These coatings and housings can help to prevent chemical damage and ensure that the camera can continue to operate effectively in harsh environments. In addition to protective coatings and housings, thermal cameras may also feature ruggedized connectors and cables that can withstand chemical exposure.

InfiRay thermal imaging cameras in chemical plants and other high-risk environmental protection staff safety

Vibration and Shock

Thermal cameras may also face challenges related to vibration and shock in harsh environments. Vibrations and shocks can cause damage to the camera's components, leading to reduced accuracy and performance. In some cases, vibrations and shocks can also cause the camera's image to become distorted or blurred, making it difficult to obtain accurate readings.

To address these challenges, manufacturers have developed thermal cameras with shock-absorbing features, such as vibration-resistant mounts and ruggedized housings. These features help to ensure that the camera can withstand vibrations and shocks and continue to operate effectively in harsh environments. Learn more about the Application of Thermal Cameras in Safety Monitoring for Coal Mines.

InfiRay Thermal Imaging Cameras Keep Workers Safe in Coal Mine Operations

Thermal cameras can be used in harsh environments, but their effectiveness will depend on the camera's design and features. InfiRay thermal imaging technology has developed thermal cameras with advanced features that can withstand extreme temperatures, high humidity, chemical exposure, vibration, and shock, allowing them to continue to operate effectively in harsh environments.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar