A Quick Guide to Thermography Method of Electrical Inspection

Thermography is a non-destructive testing method that uses infrared thermal imaging to detect and measure the temperature variations of an object. In the field of electrical inspection, thermography has become an increasingly popular method for identifying potential issues with electrical systems. By using this method, inspectors can quickly and easily detect areas of overheating, loose connections, and other problems that could lead to equipment failure or even electrical fires.

If you are interested in learning more about the thermography method of electrical inspection, this quick guide will provide you with all the essential information you need.

How Does Thermography Work?

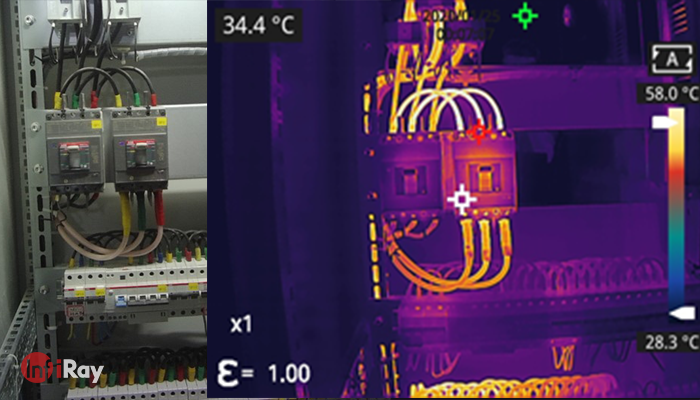

Thermography works by detecting the infrared radiation emitted by an object, which is directly related to its temperature. A thermographic camera converts this radiation into a visible image that shows the temperature variations of the object. In electrical inspection, thermography is used to detect hot spots that can indicate potential issues with the electrical system. Expanded reading: Everything You Need to Know about Thermal Camera.

Although the InfiRay AT20 is easy to install, significant temperature differences can be seen in the thermal images

Why is Thermography Useful for Electrical Inspection?

Thermography is a valuable tool for electrical inspection because it allows inspectors to identify potential issues that might not be visible to the naked eye. For example, loose connections or damaged insulation can cause an increase in resistance, which can generate heat that is not easily visible. By using thermography, inspectors can quickly and accurately identify these hot spots and take action to prevent further damage or failure.

In addition to identifying potential issues, thermography is also useful for routine maintenance and monitoring of electrical systems. By regularly inspecting electrical equipment using thermography, inspectors can identify trends and patterns that might indicate developing problems. This allows them to take proactive measures to prevent equipment failure and extend the lifespan of electrical systems.

InfiRay AT31F/61F can be linked to external alarm devices for preventive detection

How is Thermography Used in Electrical Inspection?

In electrical inspection, thermography is used to detect and measure the temperature variations of electrical components. This includes switches, breakers, transformers, motors, and other equipment. By identifying areas of overheating, inspectors can pinpoint potential issues and take corrective action.

Thermography is also used to inspect electrical panels and cabinets. These enclosures can often be difficult to access and inspect visually, but thermography can quickly and easily identify hot spots that might indicate loose connections, damaged insulation, or other issues. For example, the InfiRay AT20 is placed in critical electrical cabinets to monitor electrical contacts, contact switches, wiring connectors, and other critical points 24/7 and push alarm information to the back office promptly. Find Thermography That Can Be Used In Electrical Inspection.

Finally, thermography is also used to inspect electrical systems during installation or retrofitting. By inspecting the system before it is energized, inspectors can identify any potential issues that might cause problems once the system is operational. This can prevent costly downtime and repairs in the future.

The image quality of InfiRay AT20 arranged in a cabinet

How Do You Perform a Thermography Inspection?

Performing a thermography inspection requires specialized equipment and training. A thermographic camera is used to capture images of the electrical system being inspected. These images are then analyzed to identify areas of overheating or other issues.

To ensure accurate results, it is important to perform thermography inspections under the right conditions. This includes ensuring that the electrical system is energized and operating under normal load conditions. Inspections should also be conducted in a stable environment with minimal air movement and without direct sunlight or other heat sources.

To perform a thorough thermography inspection, it is important to inspect all accessible electrical components, including switches, breakers, transformers, and motors. Inspectors should also inspect electrical panels and cabinets, as well as any other components that might generate heat.

In conclusion, thermography is a valuable tool for electrical inspection that allows inspectors to quickly and accurately identify potential issues with electrical systems. By detecting areas of overheating and other problems, inspectors can take proactive measures to prevent equipment failure and extend the lifespan of electrical systems. If you are interested in having your electrical system inspected using thermography, be sure to contact a qualified and experienced inspector who can provide you with the reliable results you need.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar