5 Applications of Thermal Imaging Cameras in the Field of Automation

Thermal imaging cameras have revolutionized the field of automation, providing a range of benefits that were previously unattainable. By utilizing infrared technology, these cameras enable automated systems to detect, monitor, and control various processes and conditions. In this article, we will explore the advantages of thermal imaging in automation and delve into five key applications where these cameras excel.

Advantages of Thermal Imaging in Automation

Thermal cameras offer numerous advantages in the realm of automation. Firstly, they provide non-contact temperature measurement, allowing for remote monitoring without physical interaction. This feature is especially useful in hazardous or hard-to-reach environments, where human intervention may be impractical or unsafe. Additionally, thermal imaging cameras provide real-time data, enabling swift decision-making and response to critical situations. Their high-speed image capture capabilities make them ideal for continuous monitoring, enhancing overall system efficiency and safety.

1. Automated Inspection:

Thermal imaging cameras play a crucial role in automated inspection processes. By detecting temperature variations, these cameras can identify defects, anomalies, or malfunctions in machinery, equipment, or products. This application is particularly valuable in industries such as manufacturing, where product quality and consistency are paramount. Thermal camera enables automated systems to conduct comprehensive inspections, leading to improved quality control, reduced downtime, and increased productivity. Extended Reading: How Thermal Cameras Help Factories Improve Product Quality and Efficiency.

InfiRay thermal camera can quickly identify products with problem.

2. Process Control

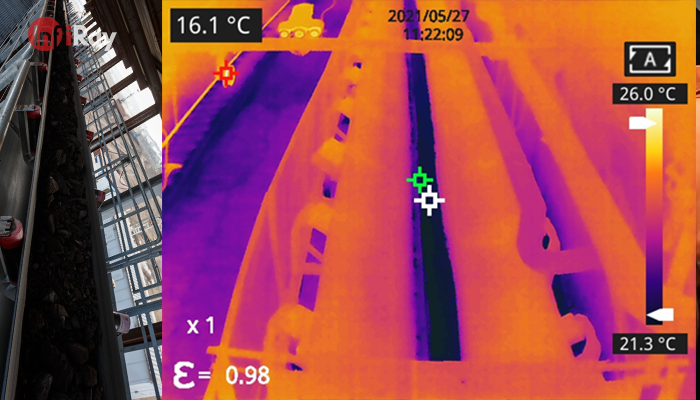

The precise control of industrial processes is essential for maintaining optimal efficiency and safety. Thermal cameras aid in process control by monitoring and regulating temperature levels. By continuously scanning the temperature of critical components, these cameras can identify deviations from desired levels and trigger automated adjustments. This proactive approach ensures that processes remain within specified parameters, minimizing the risk of system failures and maximizing productivity.

InfiRay thermal camera detects conveyor operation.

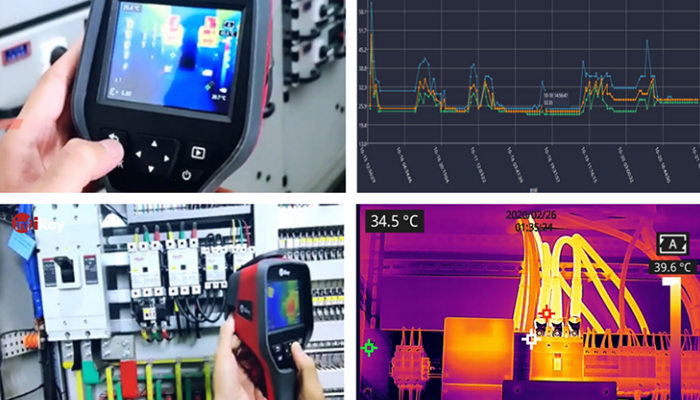

3. Condition Inspection

Regular monitoring of equipment and infrastructure is crucial for preventing unexpected failures and costly repairs. Thermal cameras offer a reliable solution for condition inspection. By detecting abnormal temperature patterns, these cameras can identify potential faults or weaknesses before they escalate into major problems. Automated systems equipped with thermal imaging technology can perform regular inspections without human intervention, significantly reducing the risk of equipment failure and optimizing maintenance schedules. Find thermal cameras that can help in condition inspection here.

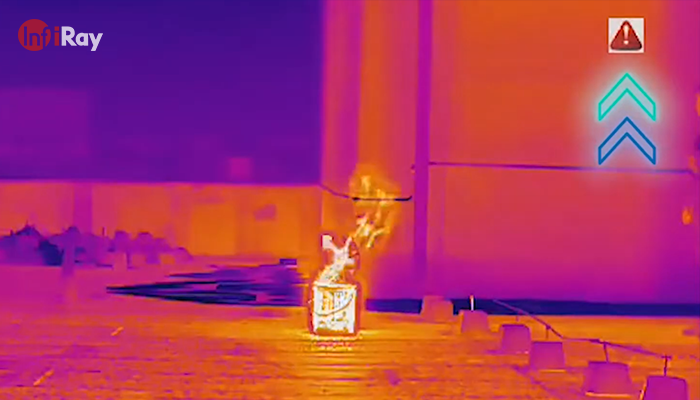

4. Fire Prevention or Detection

In automated environments, the risk of fire poses a significant threat to both personnel and assets. Thermal imaging cameras excel in fire prevention and detection applications by identifying abnormal heat patterns or hotspots that may indicate an impending fire. These cameras can trigger automated responses, such as activating fire suppression systems, sounding alarms, or alerting designated personnel. By providing early warning and enabling swift action, thermal cameras enhance fire safety measures and minimize the potential damage caused by fires.

InfiRay thermal camera can give early warning of the fire point.

5. Continuous Optical Gas Imaging

Certain industries, such as oil and gas, face the challenge of monitoring fugitive gas emissions to ensure compliance with environmental regulations. Thermal imaging cameras equipped with gas-specific filters enable automated systems to detect and visualize gas leaks in real time. By continuously monitoring gas emissions, these cameras facilitate proactive leak detection, helping industries minimize environmental impact and prevent safety hazards associated with gas leaks. Find the Thermal Camera for Gas Detection Here.

As automation continues to evolve, the demand for efficient and reliable monitoring solutions grows. Thermal cameras offer a versatile and valuable tool for enhancing automation processes across various industries. Their ability to provide non-contact temperature measurement, real-time data, and automated response makes them indispensable for the automation field. By incorporating thermal imaging technology into automated systems, businesses can enhance productivity, improve safety, and reduce maintenance costs.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar