InfiRay Thermal Cameras for 24-hour Continuous Safety Assurance of Hydrogen Supply Stations

The hydrogen energy industry in China is starting. A comprehensive understanding of the danger of hydrogen and safe exploitation of hydrogen energy are the basis for hydrogen energy development in China. Hydrogen is colorless, odorless, non-toxic, flammable, and explosive. If the safety measures are not properly implemented during exploitation, fires and explosions are likely to occur, resulting in personnel injury and deaths, as well as financial losses. Traditional monitoring methods can be used only for fixed-point measurement, while the thermal camera can implement large-area measurement, to quickly and accurately obtain the temperature distribution of the entire area, and effectively prevent accidents and reduce energy consumption.

I. Unique Advantages of the Thermal Cameras Used for Safety Monitoring of Hydrogen Supply Stations

1. Non-contact temperature measurement can ensure the safety of onsite personnel while avoiding interference with the equipment operation to the maximum extent

2. 24-hour real-time observation can help quickly discover problem points, and offer causal analysis after the risks are handled, to ensure safety in manufacturing

3. Visual temperature display offers clear temperature information about the measured targets. The measurement range is wider, and staff can intuitively discover the temperature change and temperature difference of different targets, to improve the safety of hydrogen supply stations

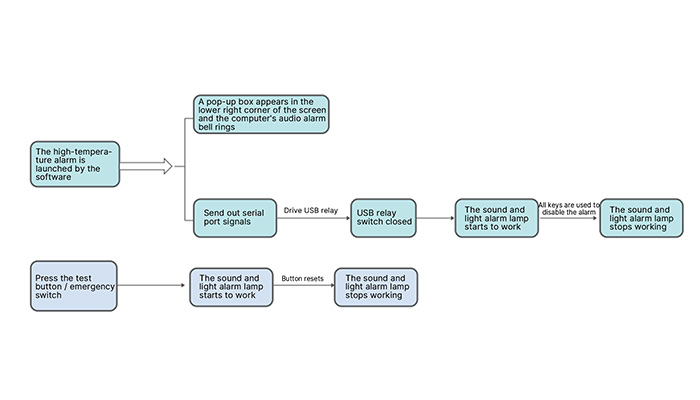

4. The automatic pre-warning function is available. The alarm system automatically monitors the target for alarms. When it discovers a problem, the alarm device is started to remind staff to take safety measures in advance.

II. Main Applications of Thermal Cameras in Safety Monitoring of Hydrogen Supply Stations

1. Temperature Monitoring of the Hydrogen Loading and Unloading Processes

Temperature rise is usually a sign of hazardous accidents. The thermal cameras can detect high-temperature combustibles present in the environment and temperature changes in the valves and pipelines, enabling temperature linkage alarms configurations in the control room and field. When the temperature exceeds the threshold, linkage alarms are generated in the control room/field.

2. Temperature Monitoring in the Hydrogen Storage Zone

Thermal cameras are used to detect the temperature changes of the hydrogen storage devices, such as the hydrogen tank. When the safe storage temperature is exceeded, an alarm is generated to inform the staff for safe handling, preventing accidents from happening.

III. Recommended Models

1. AT31/61 Electric Focusing Online Temperature Measurement Thermal Camera

Measures Temperature, to See and to Analyze

Automatic focusing: More convenient field application

POE power supply: simplified cabling

Comprehensive software functions: Correlation with external alarm devices

SDK for multiple platforms: Secondary development support

2. AT31F/61F Fixed Focusing Online Temperature Measurement Thermal Camera

It measures temperature for visible reading and analysis

Wide-angle lens: No blind spot

I/O alarm output: Correlation with external alarm devices

Port 485: Linked PTZ

Comprehensive software functions: All-round analysis of temperature data

IV. Installation Solution Example

InfiRay proposes the following installation solution based on the customer's needs and actual field situation:

1. A combination of multiple alarms is adopted. If there is a temperature exception, all related personnel in the control room and on the field are notified for evacuation or emergency safety measures.

2. With the PTZ, the tube trailer tails and hydrogen storage zones can be fully covered for monitoring.

V. Software Solution

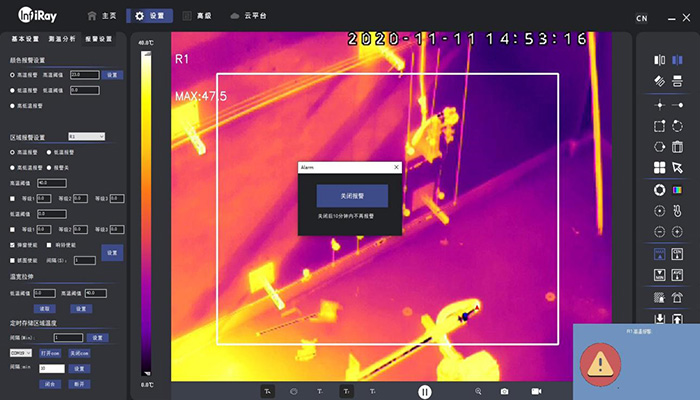

Use with InfiRay's professional temperature measurement software is recommended:

1. Supports palette selection and configuration of measurement tools, which can be flexibly and easily applied to provide a simple way for temperature data collection at the backend

2. Can send abnormal temperature alarms and supports multi-level alarm configuration

3. Automatically generates curves of temperature data and temperature reports for effectively monitoring temperature changes of the hydrogen supply station

4. The temperature measurement software supports networked access of multiple devices, providing video previews with up to 64 real-time images

VI. How Can I Produce a Thermal Image of Premium Quality?

Please refer to the following suggestions for using a thermal imager to produce a thermal image of premium quality:

1. Select thermal imagers with high thermal sensitivity for scenarios with a small regional temperature difference

2. Select thermal cameras or levels of proper measurement ranges for different scenarios and temperature

3. Use automatic measurement first, and then enable the temperature width stretch function. Manually set the temperature width to the minimum and include the previously measured temperature range to enrich the image details

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar