How to Choose Industrial Thermal Camera?

With the rapid development of industrial production technologies, intelligent thermal cameras have become indispensable equipment for many industrial scenarios, to not only meet the monitoring demands of new industrial scenarios, but also realize the update and replacement of traditional industrial temperature measurement methods.

Infrared thermal imaging technology is widely used. There are demands for thermography and monitoring in many traditional industries, such as smelting equipment monitoring in the metallurgical industry, production and transportation temperature measurement in the petrochemical industry, fire prevention and warning in the coal industry, and equipment maintenance in the power industry. New application scenes have been found in emerging industries, such as lithium-ion battery storage and test monitoring in the new energy industry, real-time monitoring of rail transit equipment, monitoring of treatment process for hazardous chemicals, and quality control of industrial precision manufacturing.

InfiRay offers an abundance of industrial thermal cameras, which are mainly divided into two product lines: online temperature measuring and monitoring industrial thermal camera and handheld industrial thermal camera. Online temperature measuring thermal cameras include the AT series, ATF fixed-focus series, AT20 card thermal camera series, fire protection series, and ultra-high temperature series; handheld thermal cameras cover the handheld C series, handheld M series, power industry T series and portable P series. Each product series offers different resolutions, lenses of different focal lengths and different communication interfaces for customers to choose.

For diversified application scenes and industrial temperature measurement products, the customer can select suitable products and solutions to meet the application requirements according to the following factors:

Different Forms for Different Scenes and Using Methods:

Handheld thermal cameras are for patrol inspection or applications where scenarios may change, such as oil pipeline patrol inspection, ground heating maintenance, and circuit board problem detection. For application in fixed scenes or detection of sizable objects, such as coal pile fire prevention, hazardous chemical warehouse monitoring, high-speed train pantograph detection, and industrial manufacturing process monitoring, online temperature measurement thermal cameras could be selected to complete 24h all-weather temperature monitoring in the area through fixed installation.

Different Models for Different Industrial Needs:

There are infrared thermal imaging demands in each industry, and specific product models could be selected according to scenarios demands. For example, in the metallurgical industry, demands are divided into:

I. Process management and control:

In the metallurgical industry, temperature shall be strictly controlled throughout the entire process for the raw materials, thermal energy required for smelting, temperature of steel and iron water, and temperature of processing parts. Thus, the online temperature measurement industrial thermal cameras plays a very critical role in the process management and control of the metallurgical industry.

II. Equipment detection:

In the daily maintenance and overhaul of the equipment, the infrared thermal imaging diagnostic technology can be used for multiple kinds of detection. For example, in detection of steel ladles and iron water, rotary kilns, and important pipelines, it marks the most effective and convenient way to detect the presence of faults with the handheld thermal cameras.

Different Resolutions for Different Definitions and Prices:

InfiRay temperature measurement industrial thermal cameras are available in different resolutions: 384×256, 640×512, 1280×1024, 1920×1080, etc. The higher the resolution, the clearer the infrared image. Products with higher resolution are more suitable for scenes requiring high-definition observation and rich details. The resolution is also proportional to the product price. So, for scenarios with low image clarity requirements, low resolution products turn out more cost-effective options.

Different Lens, FOV, and Focusing Modes for Different Operating Distance and Object Sizes:

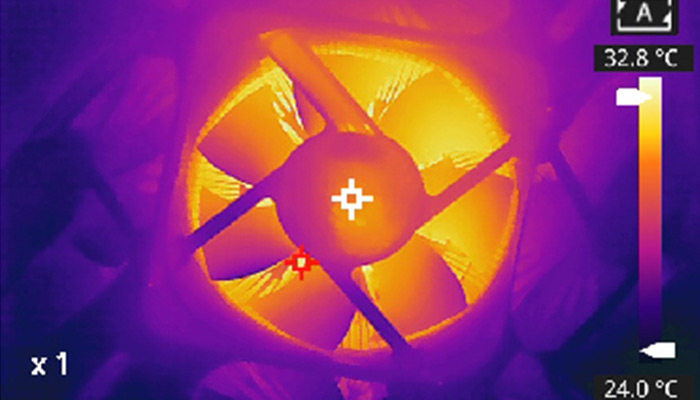

The lens focal length determines the distance to be measured, and the infrared FOV is the field of view that can be observed by the photoelectric equipment. When the distance is certain, the infrared FOV determines the monitoring coverage. So, in selection of lens parameters, the measurement distance and the object to be detected will be estimated, to calculate the appropriate lens focal length and infrared FOV. Fixed-focus or zoom lenses could be selected to detect fixed and moving targets. When the detected object moves back and forth, it often produces a non-solid focus to output blurred images. Thus, a clear image could be obtained by lens focusing.

Others:

For other functions, AT31U is ideal for ultra-high temperature application, with a temperature measuring range of 0 - 1500°C. T series handheld thermal camera is optimum for electric device maintenance. P series portable thermal camera, with a compact size and adjustable rotating lens, are best for narrow space applications.

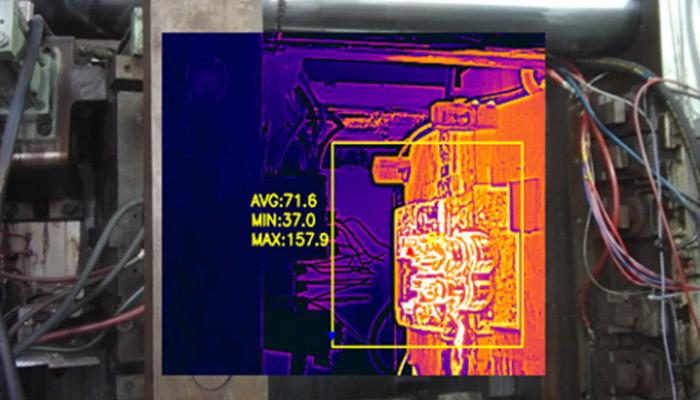

InfiRay temperature measurement industrial thermal cameras adopt advanced engineering image processing algorithms and cutting-edge infrared chips. The use of temperature measurement industrial thermal camera has the following advantages:

The system operates 24 hours a day in all-weather without interference;

The industrial thermal camera can accurately measure the temperature of the whole process in real time to provide automatic tracking of spots of abnormal temperature;

The infrared images can be used for secondary analysis offline to display the temperature at any pixel;

The control end locates the spot of abnormal temperature to help the technicians repair the equipment failure area in time.

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar