Application of the Thermal Cameras in the Dairy Industry: To Promptly Discover Diseases in Dairy Cows and Goats

Mastitis, a common disease for dairy cows and goats, is a big problem for the modern dairy industry. In the past, farmers could discover the disease with their experience in the milking process. However, the modernized milking machine replaces the manual milking process, making it difficult to sense the udder temperature rise, which is a sign of mastitis deterioration. Currently, only the milk is tested in labs for most farms, to obtain its biochemical and physiological indicators. This method cannot promptly discover the diseases in dairy cows and goats. The thermal camera can help staff on the farm promptly discover diseases, prevent the disease spread and deterioration of dairy cows and goats, and avoid their deaths and financial losses.

I. Main Applications of Thermal Cameras in the Dairy Industry

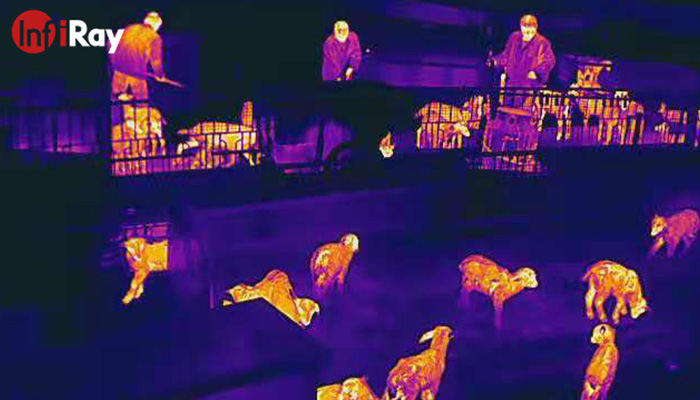

1. Observing Whether There Are Body Temperature Exceptions in Dairy Cows and Goats

Usually, the body temperature rise is a symptom of the cow and goat epidemic. The feeders can use the thermal camera to observe and record the body temperature changes of cows and goats to discover epidemics for prompt quarantine and medical treatment.

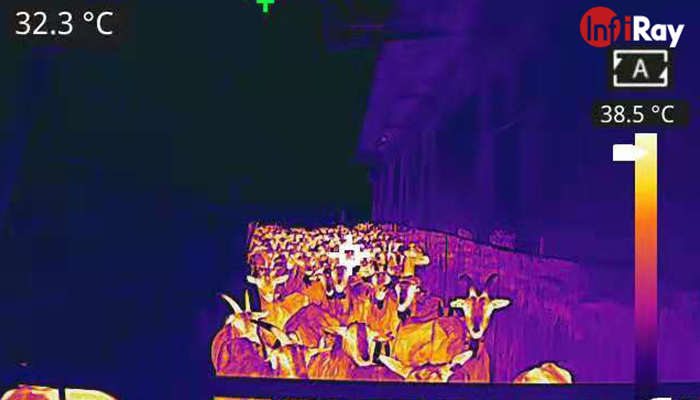

2. Observing Whether There Is Local Fever in the Breasts of Dairy Cows and Goats

Local inflammation or physiological condition changes of animals will damage or affect the entire-body or local heat balance, and the clinical manifestation is tissue temperature rise or reduction. Normally, the left and right udders of a dairy cow are symmetric. The thermal camera can detect the temperature difference between the left and right udders. If the temperature exceeds a certain value, it can be preliminarily determined that the breast with a temperature rise has mastitis.

II. Unique Advantages of Thermal Cameras in the Dairy Industry

1. Remote and non-contact temperature measurement makes the measurement process more hygienic and safer

2. 24-hour real-time measurement and automatic capture of the highest temperature point in the entire screen or an area can help locate the point of animal fever in a reliable and prompt manner, improving feeders' work efficiency

3. With a visual temperature display, feeders can see the temperature of the target more clearly. The temperature range is wider for feeders to discover the temperature change and temperature difference of animals on the farm

4. The automatic pre-warning function is available. The alarm system automatically monitors the target for alarms. When it discovers a problem, the alarm device is started to remind feeders to take measures in advance.

III. Recommended Models

AT300/600 Online Thermal Camera

| Frame rate of 50Hz, real-time temperature data transmission

| Patented intelligent compensated temperature measurement algorithm, measurement accuracy of ±0.3°C

| Provide SDK, and support secondary development by customers

| Compact structure, easy installation

2. C200H Handheld Thermal Camera

| Accurate handheld measurement within 1 to 5 meters, measurement accuracy of ±0.5°C

| Dual-spectrum fusion, easy identification of fever points

| High/low-temperature tracking, quick discovery of abnormal temperature points

| Sufficient power, with ultra-long battery life of 11 hours

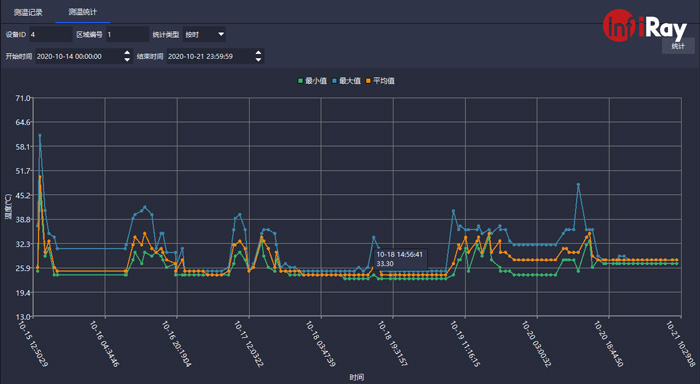

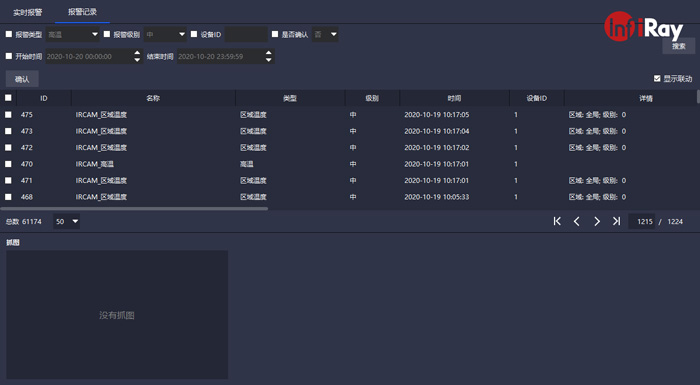

IV. System Software

Use with InfiRay's professional temperature measurement software is recommended:

1. Temperature distribution on the farm is automatically scanned to generate intuitive images and the point with the highest temperature is automatically captured. When the temperature reaches the preset threshold, the system software displays the alarm temperature and the image of the position where the temperature is high

2. Supports palette selection and configuration of measurement tools, which can be flexibly and easily applied to provide a simple way for temperature data collection at the backend

3. Automatically generates curves of temperature data and temperature reports for effectively monitoring of temperature changes of animals on the farm

4. The temperature measurement software supports networked access of multiple devices, providing video previews with real-time images

V. How Can I Produce a Thermal Image of Premium Quality?

Please refer to the following suggestions for using a thermal imager to produce a thermal image of premium quality:

1. Select thermal imagers with high thermal sensitivity for scenarios with a small regional temperature difference

2. Select thermal imagers or levels of proper measurement ranges for different scenarios and temperature

3. Use automatic measurement first, and then enable the temperature width stretch function. Manually set the temperature width to the minimum and include the previously measured temperature range to enrich the image details

français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  日本語

日本語  한국어

한국어  magyar

magyar